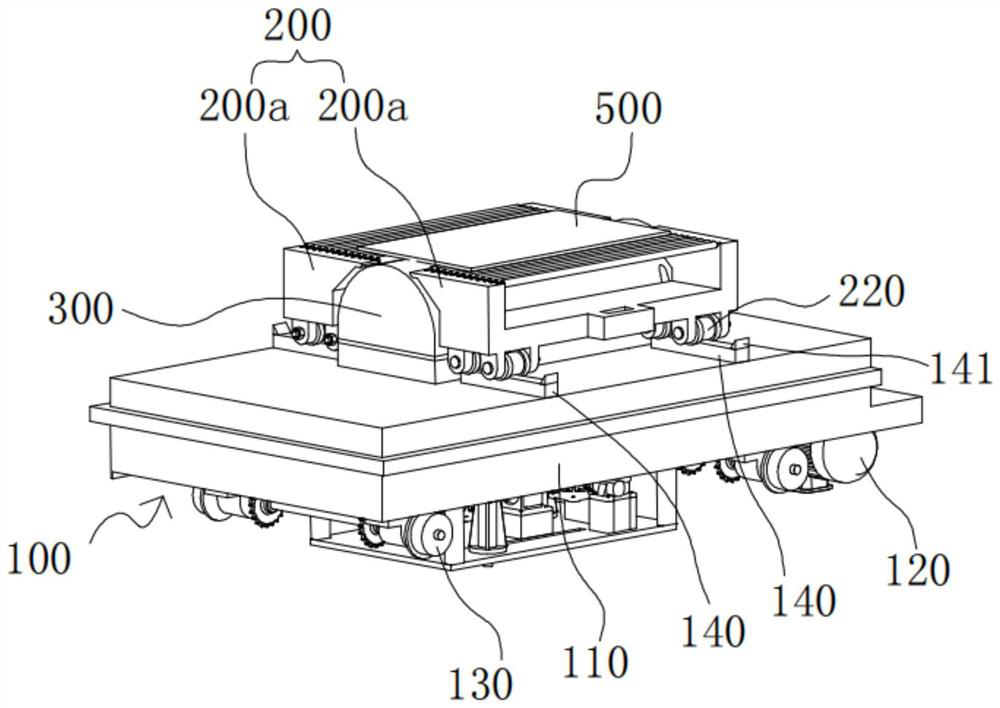

Kiln car and kiln for curved surface ceramic rock plate production

A kiln car and ceramic technology, applied in the field of kiln cars and kilns, can solve the problems of poor process controllability, high production cost, long production cycle, etc., and achieve the effect of simple process, low production cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The kiln in this embodiment takes a bogie kiln as an example.

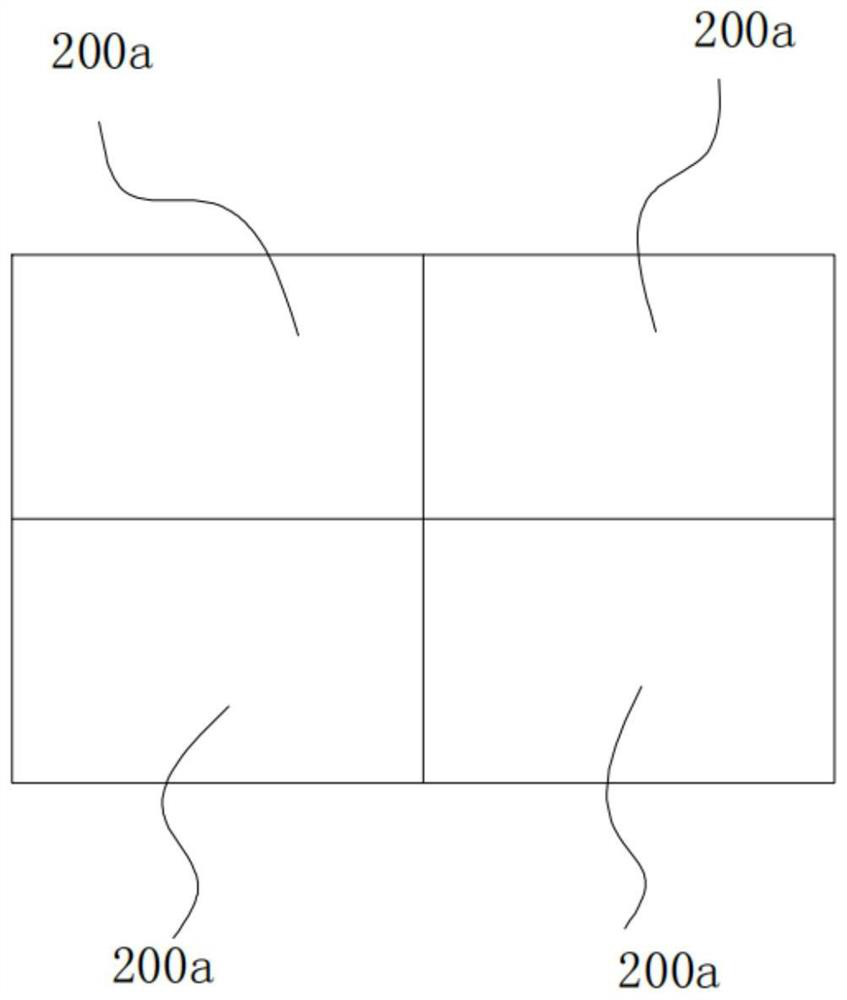

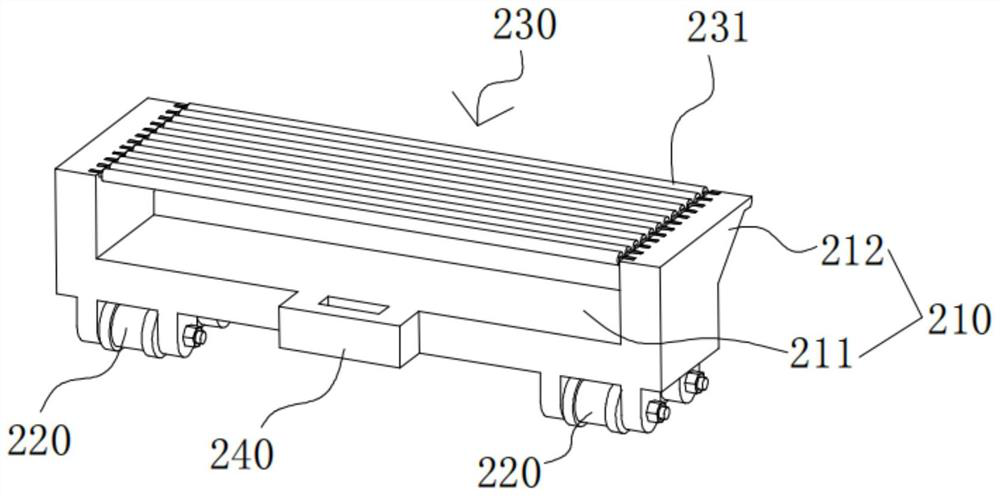

[0071] Step S100, when the kiln car of the above-mentioned embodiment is located outside the kiln, the ceramic tile blanks after the pressing process of the ceramic press, drying, glaze line coating, and inkjet printing are used to use the external roller table and the rollers provided on the kiln car. The roller platform is transferred to the kiln car in the way of docking. At this time, the roller platform is located close to the arc-shaped mold body. support, and the center of the ceramic brick must be located at the vertex of the arc-shaped mold body.

[0072]In step S200, after the kiln car enters the kiln, the kiln in this embodiment takes the trolley furnace as an example, and the kiln operates in the form of intermittent operation, then the lifting furnace door is closed accordingly to make the combustion system and the exhaust system work, The kiln is heated and heated until the ceramic brick 500 ...

Embodiment 2

[0077] The kiln in this embodiment takes a tunnel kiln as an example.

[0078] Step S100, when the kiln car of the above-mentioned embodiment is located outside the kiln, the ceramic tile blanks after the pressing process of the ceramic press, drying, glaze line coating, and inkjet printing are used to use the external roller table and the rollers provided on the kiln car. The roller platform is transferred to the kiln car in the way of docking. At this time, the roller platform is located close to the arc-shaped mold body. support, and the center of the ceramic brick must be located at the vertex of the arc-shaped mold body.

[0079] In step S200, the kiln car moves into the preheating zone of the kiln accordingly. As the kiln car moves, the temperature in the kiln where the ceramic bricks are located gradually increases, and the strength of the ceramic bricks increases. When the body supports the whole piece of ceramic brick by its own weight and the ceramic brick does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com