Complete removable denture resin block and digital complete removable denture manufacturing method

A technology of removable dentures and complete dentures, which is applied in medical science, dentistry, dental prosthesis, etc., can solve the problems of occlusal relationship prone to errors, difficult operation, and hidden dangers of firmness, and achieve low professional requirements and production Simple method, consistent effect of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] see Figure 1-Figure 5, the present embodiment also provides a method for making a digital removable denture resin block for a full-mouth removable denture, which is mainly used to make the above-mentioned full-mouth removable denture resin block, including the following steps:

[0048] (1) Data scan of teeth and jaws:

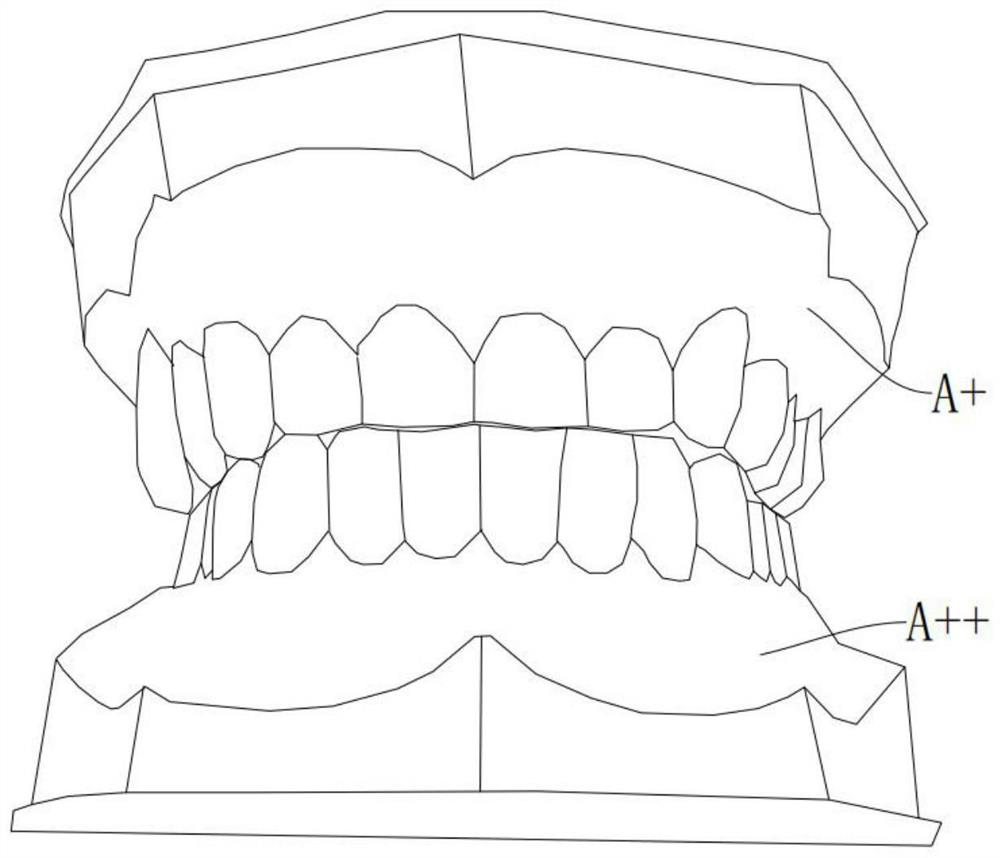

[0049] The dental model scanner is used to collect data on the patient's mouth. After scanning, the upper and lower jaw 3D data are obtained. Then the software automatically matches the upper and lower jaw models to obtain the upper and lower jaw model data, and then save the upper and lower jaw model data in STL format, respectively. The mandibular model data forms the dental jaw data A required for CAD design. The dental and jaw data A of the patient is collected mainly to facilitate the production of a dental and jaw bone model identical to the patient's dental and jaw bone. The dental and jaw data A obtained by scanning can be divided into upper d...

Embodiment 2

[0066] see Figure 6-Figure 8 , this embodiment provides a method for manufacturing a digital full-mouth removable denture, which uses the first embodiment and includes the following steps:

[0067] 1) Scanning data of patient's teeth and jaws:

[0068] The dental model scanner is used to scan the intraoral jaw model, and then the software automatically matches the upper and lower jaw models. After scanning, the upper and lower jaw three-dimensional data E consistent with the patient's jaw are obtained, and then the upper and lower jaw model data are saved in STL format respectively. , the mandibular model data to form the maxillary base data F required for CAD design;

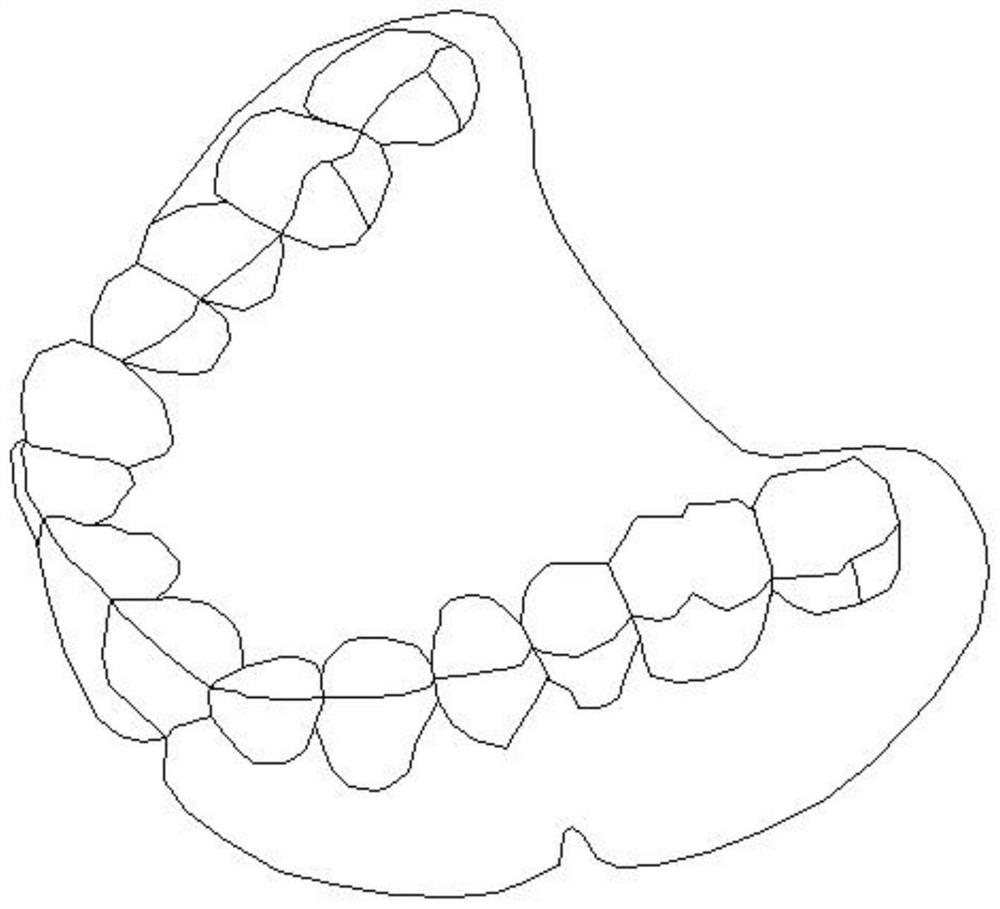

[0069] 2) Jaw design:

[0070] Using the denture CAD design software, match the maxillary base data F to the gingival boundary resin block model data C, match the upper teeth at the gum line of the model data C to design the upper and lower jaw data H of the full-mouth removable denture, and use STL The for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com