Prediction method for yield and recovery rate of pyrrhotite and application thereof

A technology of pyrrhotite and prediction methods, which is applied in the direction of prediction, data processing applications, instruments, etc., can solve the problems of no process parameters, process condition parameters are not given, and influencing factors are not considered, so as to reduce the prediction error , improve accuracy, and efficiently separate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] This embodiment provides a method for predicting the yield and recovery rate of pyrrhotite in a pyrite concentrate, wherein the main minerals in the pyrite concentrate are pyrrhotite and chalcopyrite, and also contain a small amount of pyrrhotite. Zinc ore and galena, so it is necessary to separate the pyrrhotite in it to achieve the purpose of desulfurization. The prediction method includes the following steps:

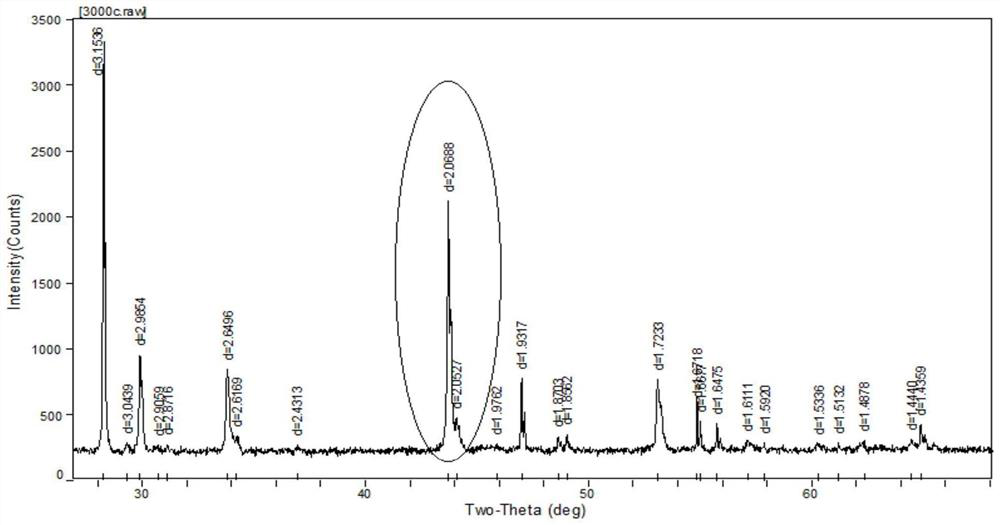

[0083] (1) Judging the crystal structure type of pyrrhotite in the pyrite concentrate: X-ray diffraction analysis is performed on the pyrite concentrate sample, and the X-ray diffraction pattern is obtained, such as figure 1 shown. from figure 1 It can be seen that the characteristic peak at about 2θ=44° is a single peak and has small bifurcations, that is, there are two types of monoclinic pyrrhotite and hexagonal pyrrhotite in the sulfur concentrate sample.

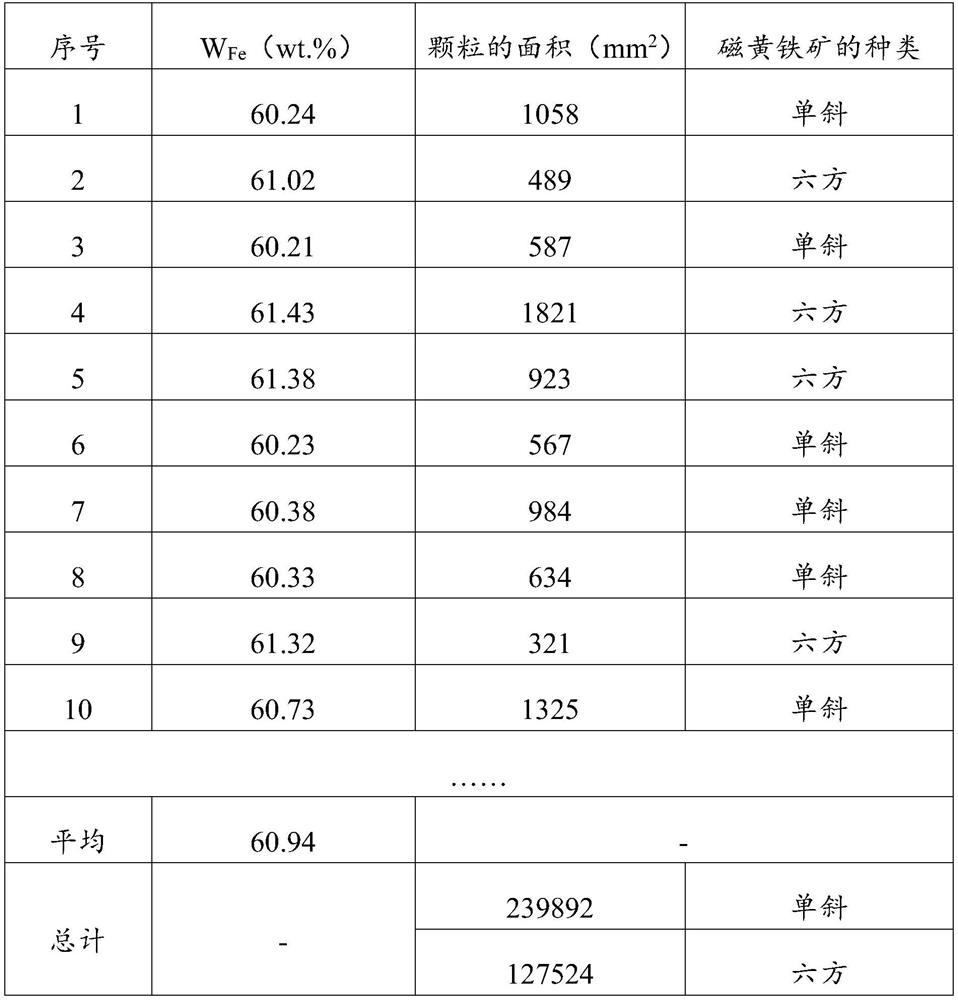

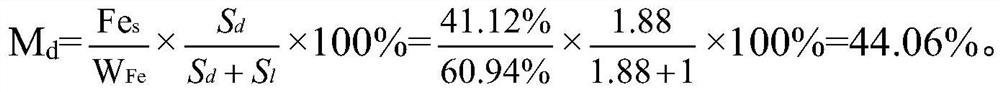

[0084] Then, calculate the mass percentage content M of monoclinic pyrrhotite in the ore to be pr...

Embodiment 2

[0112] The present embodiment provides a method for sorting pyrrhotite, comprising the following steps:

[0113] (1) sulphur concentrate sample (this sample is the same as the sample adopted in Example 1) processing:

[0114] The samples were subjected to grinding treatment based on the grinding fineness established by the actual ore feeding. When the grinding fineness is less than 0.074mm accounting for 80%, the dissociation degree of chalcopyrite monomer in the sulphur concentrate sample is 92%, the monomer dissociation degree of pyrrhotite is 95%, valuable minerals and magnetic The pyrite has basically been completely dissociated.

[0115] (2) X-ray diffraction analysis of sulphur concentrate samples:

[0116] According to the X-ray diffraction pattern obtained in Example 1, it can be known that the pyrite concentrate sample contains both monoclinic pyrrhotite and hexagonal pyrrhotite.

[0117] (3) Perform magnetic separation according to the crystal structure type: it c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com