Steelmaking end point prediction method based on neural networks

A prediction method and neural network technology, which are applied in the field of steelmaking automation control, can solve the problems of inaccurate flame information acquisition, inaccurate training of neural network parameters, and large prediction errors, so as to achieve small prediction errors and overcome artificial experience prediction. , the effect of accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below by means of embodiments in conjunction with the accompanying drawings.

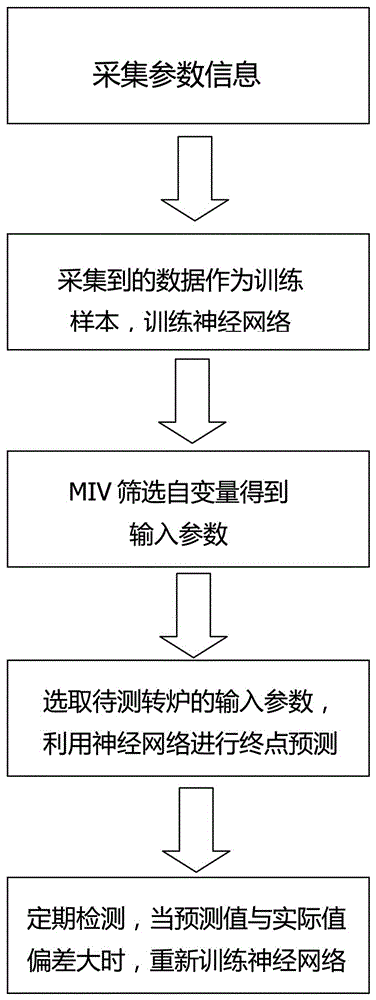

[0023] like figure 1 As shown, it is a flow chart of the neural network-based end point prediction of converter steelmaking according to the embodiment of the present invention. The method includes:

[0024] S1. Collect multiple groups of parameter information in converter steelmaking. The parameter information includes the weight of molten iron, temperature of molten iron, carbon content, steel scrap quality, oxygen lance blowing time, oxygen lance position and oxygen blowing volume; these parameters are directly passed through the production equipment Obtain. Since the molten steel in the converter shows a violent reaction and is covered with slag, the conventional flame information collected directly from the furnace mouth is not accurate. Therefore, in this embodiment, a vent is provided on the side wall of the converter, and a The ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com