Semiconductor packaging element testing device

A technology for packaging components and testing devices, applied in the field of testing devices for semiconductor packaging components, can solve the problems of inconvenience in testing semiconductor packaging components, the test process is not smooth, and the semiconductor packaging components cannot be fixed, and the effects of preventing loosening and incomplete testing can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

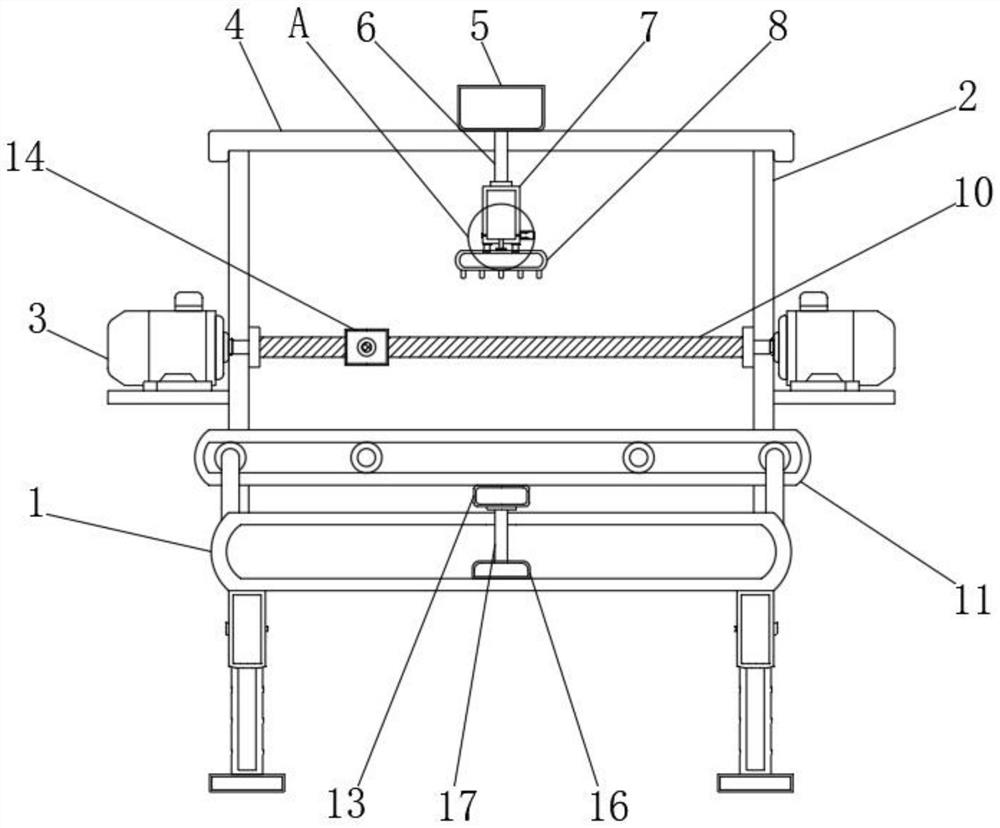

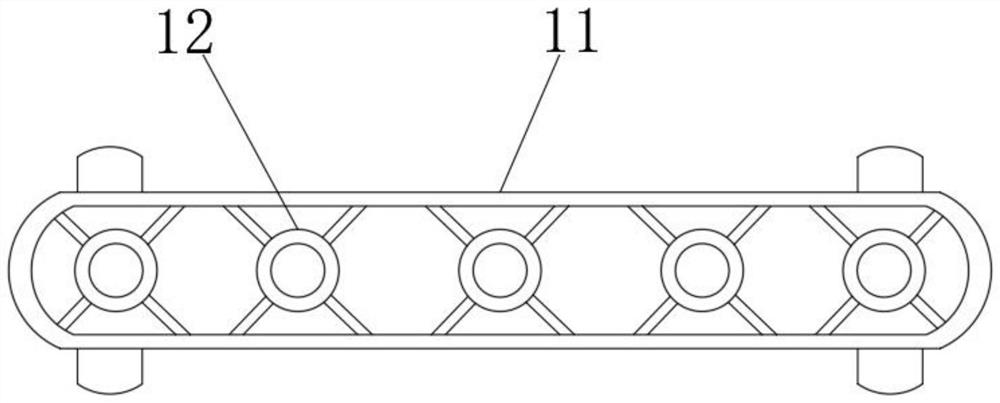

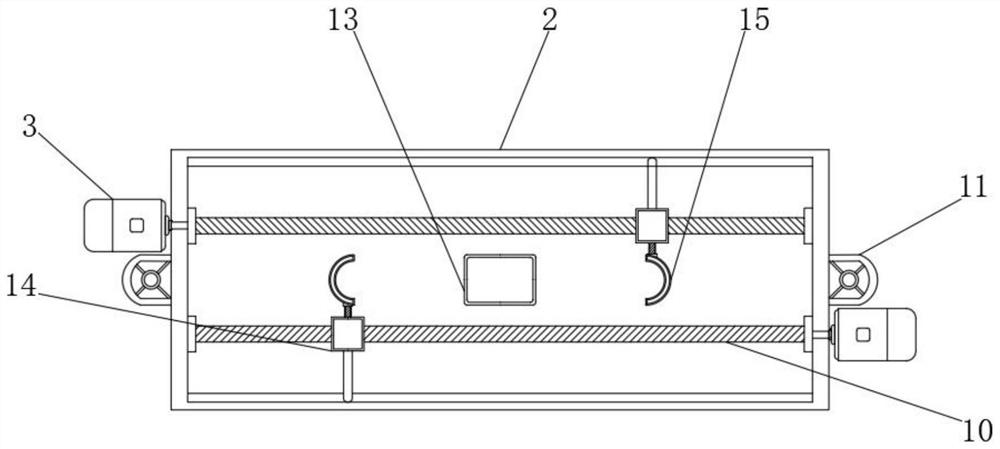

Embodiment 1

[0040] The present invention provides a technical solution, a semiconductor package component testing device, comprising a support base 1 , a fixed connection plate 2 , a drive motor 3 , a connection cover plate 4 , a first hydraulic cylinder 5 , a first piston rod 501 , and a connection column 7 , test board 8, test probe 9, threaded rod 10, conveyor belt 11, placement groove 12, test table 13, sliding connection block 14, semicircular clamp 15, second hydraulic cylinder 16, second piston rod 17, rotating gear 18 and translation tooth plate 19, see figure 1 , the top of the support base 1 is fixedly installed with a fixed connection plate 2, both sides of the fixed connection plate 2 are fixed with a drive motor 3, and the top of the fixed connection plate 2 is movably equipped with a connection cover plate 4, and the connection cover plate A first hydraulic cylinder 5 is movably installed at the top center position of the connecting cover plate 4, and a first piston rod 501 ...

Embodiment 2

[0044] On the basis of Example 1, as Figure 6-8 As shown, the lifting support column includes:

[0045] The fixed seat 6, the inner left and right sides of the fixed seat 6 are symmetrically provided with a movable cavity 1 601, a movable cavity 2 602, and a movable cavity 3 617, and the movable cavity 2 602 penetrates the upper end of the fixed seat 6 and communicates with the outside world, so The second movable cavity 602 is communicated with the third movable cavity 617, the left and right ends of the fixed seat 6 are symmetrically provided with open grooves 604, and the lower end of the open groove 604 is provided with a second groove;

[0046] Two rotating blocks 603, the two rotating blocks 603 are respectively rotated and arranged in the opening grooves 604 at the left and right ends, the lower end of the rotating block 603 is provided with a groove one 605, the groove one 605 and the groove The two are arranged correspondingly, and the second groove is slidably conn...

Embodiment 3

[0057] On the basis of embodiment 1, also include:

[0058] Force sensor 1: The force sensor 1 is arranged at one end of the semicircular fixture 15 on the left side away from the sliding connection block 14, and is used to detect the force that the semicircular fixture 15 on the left side receives during semiconductor testing;

[0059] Force sensor 2: The force sensor 2 is arranged at the end of the right semi-circular fixture 15 away from the sliding connection block 14, and is used to detect the force received by the right semi-circular fixture 15 during semiconductor testing;

[0060] Alarm: the alarm is arranged outside the support base 1;

[0061] Controller: the controller is electrically connected with the first force sensor, the second force sensor and the alarm;

[0062] The controller controls the alarm to work based on the first force sensor and the second force sensor, including the following steps:

[0063] Step 1: The controller calculates the theoretical allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com