Copper bar tinning equipment for new energy automobile circuit control system

A new energy vehicle, circuit control technology, applied in the direction of electrolysis components, electrolysis process, cleaning methods and utensils, etc., can solve the problems of waste of residual liquid, affecting the effect of tin plating, volatilization, etc., to avoid waste, improve the efficiency of tin plating, The effect of avoiding gas volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

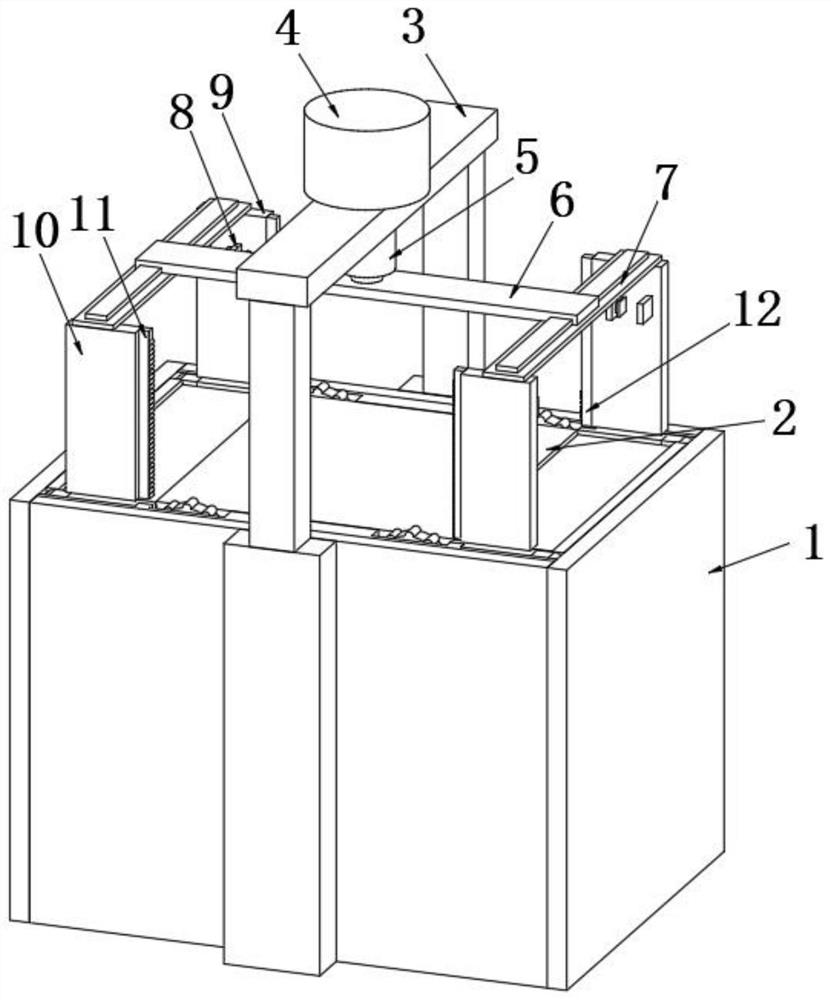

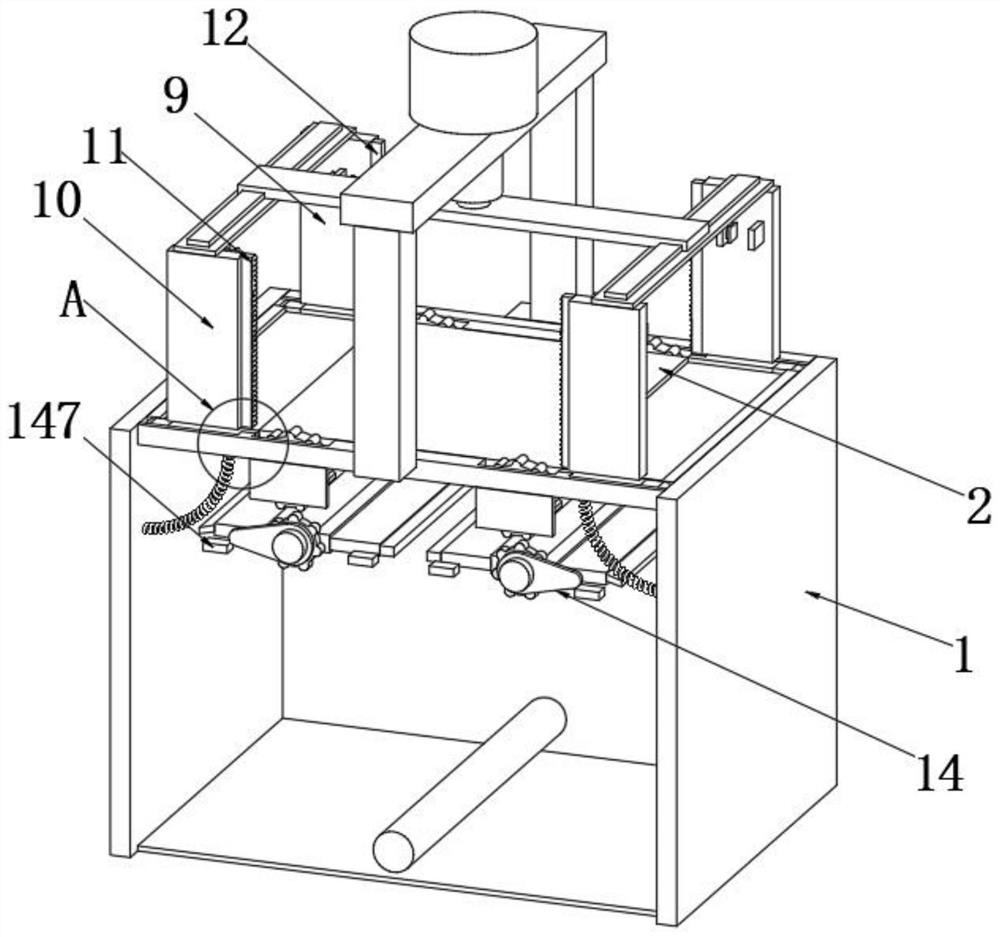

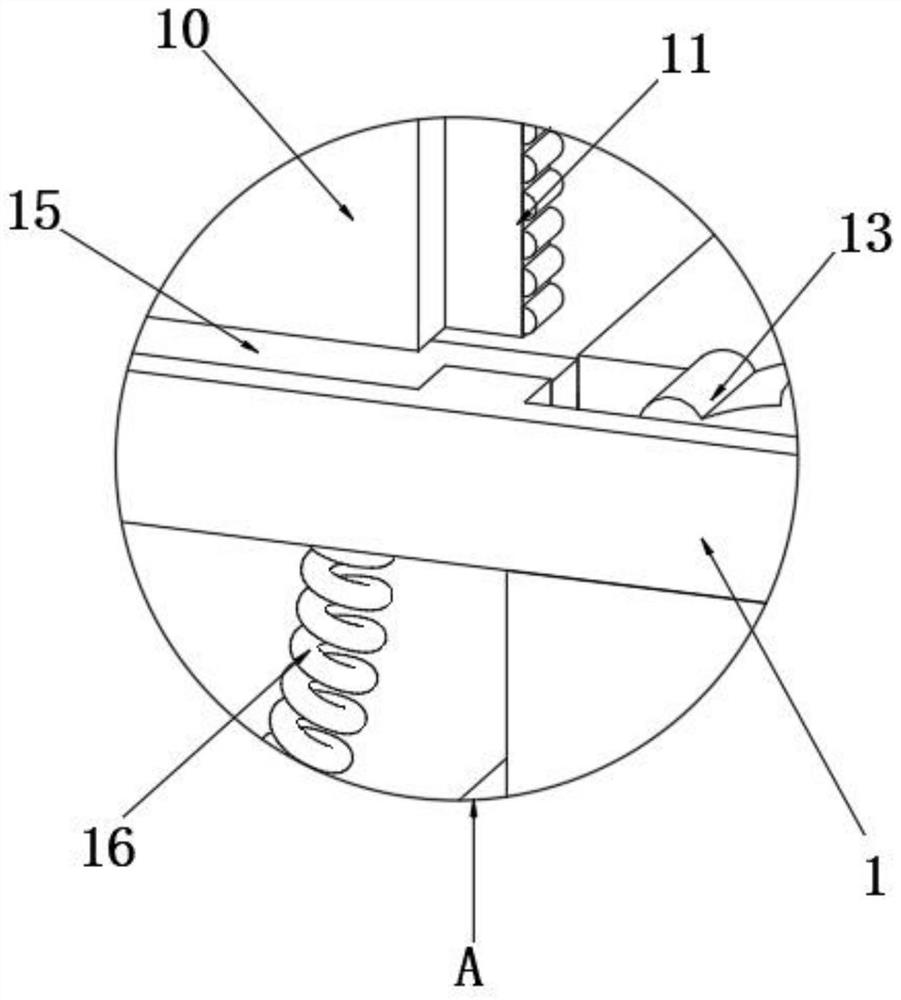

[0030] see Figure 1-8As shown, the present invention is a copper bar tinning equipment for a circuit control system of a new energy vehicle, including a processing box 1, a sealing plate 2 is fixedly connected to the upper surface of the processing box 1, and a fixing frame 3 is fixedly connected to the upper surface of the processing box 1 , the side of the fixing frame 3 away from the processing box 1 is fixedly connected with a positioning cylinder 4, the side of the fixing frame 3 away from the positioning cylinder 4 is fixedly connected with a telescopic rod 5, and the side of the telescopic rod 5 away from the fixing frame 3 is fixedly connected with a horizontal plate 6. The lower surface of the horizontal plate 6 is symmetrically and fixedly connected with a positioning plate 7, and the lower surface of the positioning plate 7 is fixedly connected with a vertical pressure plate 2 10 and a vertical pressure plate 9 from front to back, and a vertical pressure plate 9 and...

Embodiment 2

[0033] During the production and use of the copper bar, if it is exposed to the air for a long time, it will be oxidized to form a film - patina, and the conductivity of the copper green is very poor, which will increase the resistance, but the existing equipment is conducting When tinning, the surface of the oxidized copper bar cannot be treated, which will affect the tinning effect of the copper bar, and there is liquid remaining on the surface of the copper bar after tin plating. When the copper bar is taken out, the residual liquid will be taken out. Take it out, causing waste of resources and polluting the environment at the same time, so it is urgent to solve the existing problems;

[0034] During the downward movement of the vertical pressure plate 1 9, the vertical pressure plate 1 9 drives the sealing teeth 131 to rotate through the single-sided toothed plate 2 12, and the sealing teeth 131 drive the cleaning mechanism 14 to rotate through the transmission between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com