Anti-corrosion antifouling paint and preparation method thereof

An anti-fouling coating and anti-corrosion technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve problems such as increased energy consumption, increased surface roughness of ships, accelerated hull corrosion, etc. The effect of improving anti-corrosion performance, improving anti-fouling performance and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

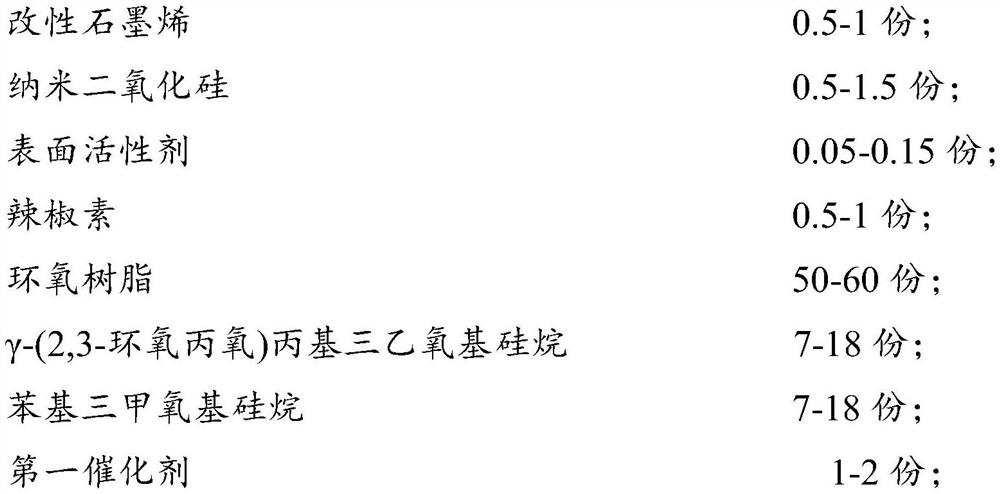

[0047] Correspondingly, the present invention also discloses a preparation method of the above-mentioned anti-corrosion and anti-fouling paint, which specifically includes the following steps:

[0048] (1) adding nano-silica into modified graphene and mixing, then adding surfactant to obtain graphene pre-dispersion;

[0049] (2) Add epoxy resin, γ-(2,3-glycidoxy)propyltriethoxysilane, phenyltrimethoxysilane and the first catalyst into the reaction kettle, under the condition of 110-120℃ Heating and stirring for 2-4h to obtain matrix resin;

[0050] (3) matrix resin, capsaicin, graphene pre-dispersion are added in the reactor and stirred to obtain matrix components;

[0051] (4) Add the composite silane coupling agent, ethyl orthosilicate and the second catalyst into the reaction kettle, heat and hydrolyze it at 55-80 ° C for 7-9 hours, and then add an anionic surfactant after cooling to room temperature to obtain the curing component ;

[0052] (5) The base component and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com