Liquid level pipe joint and wafer cleaning equipment capable of obtaining accurate liquid level information in absence of liquid

A technology for cleaning equipment and liquid level tubes, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, liquid/fluid solid measurement, etc., and can solve the problem of liquid level sensor 4 outputting wrong liquid level information and liquid level tube 2 liquid not being timely Discharge, cleaning fluid can not completely discharge light and other problems, to achieve the effect of reducing the surface tension of the liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

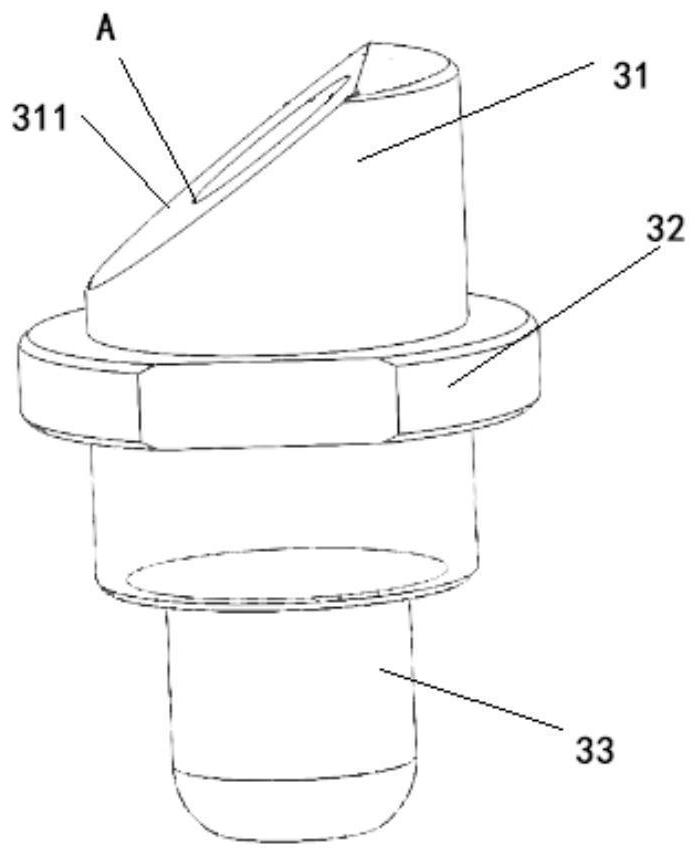

[0037] This embodiment provides a liquid level pipe joint, such as figure 2 As shown, the liquid level pipe joint is arranged at the bottom of the tank body 1 to connect the liquid level pipe 2 with the bottom of the tank body 1. The liquid level pipe joint 3 has a channel in the middle, including the upper end extending into the bottom of the tank body 1. part 31, the lower end part 33 connected with the liquid level pipe 2, the flange 32 between the upper end part 31 and the lower end part 33, the top surface of the upper end part 31 has an inclined surface, so that the plane where the opening of the upper end part 31 is located is the same as the horizontal plane An included angle is formed (that is, an acute angle is formed, preferably 30°-60°), and the lowest point of the opening of the upper end 31 ( figure 2 A point in ) is not higher than the inner wall of the bottom of the tank body 1.

[0038] In the liquid level pipe joint of this embodiment, the structure of the...

Embodiment 2

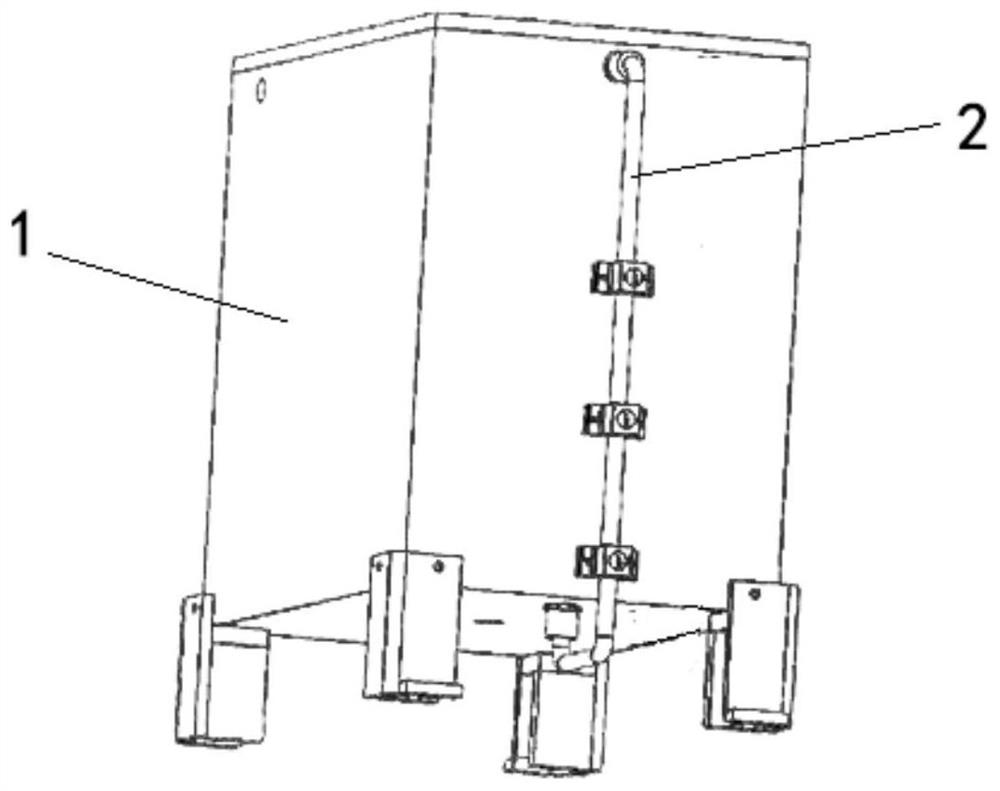

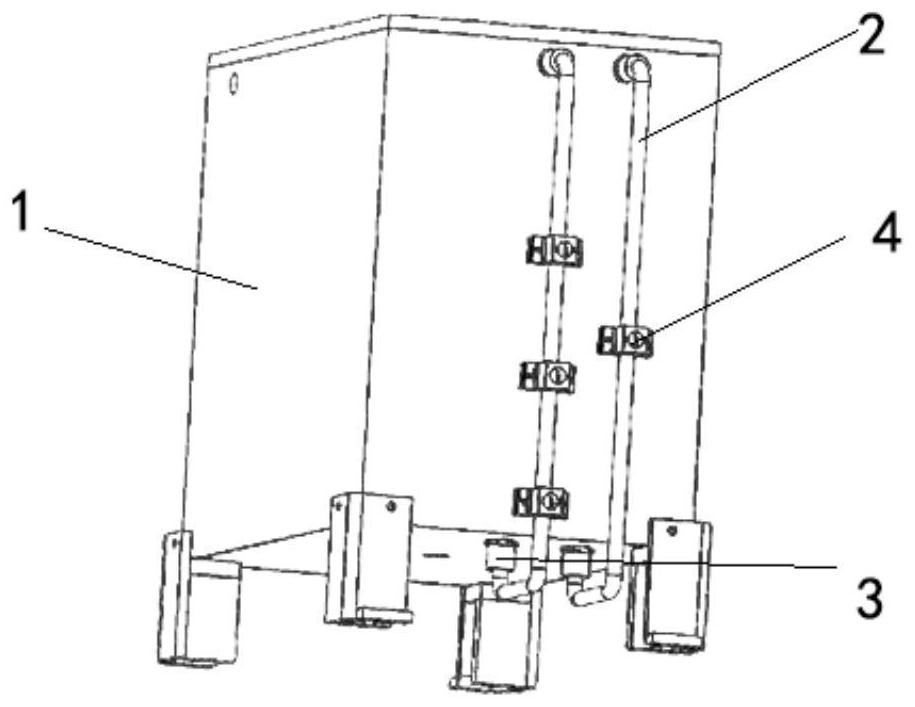

[0044] This embodiment provides a wafer cleaning device with accurate liquid level information when there is no liquid, including:

[0045] tank 1;

[0046] The liquid level pipe 2 is vertically arranged on the outer wall of the tank body 1, the bottom of the liquid level pipe 2 is communicated with the bottom of the tank body 1, and the top of the liquid level pipe 2 is communicated with the top of the tank body 1 or is an opening;

[0047] The liquid level sensor 4 is arranged on the liquid level pipe 2 and is used for sensing the liquid level height in the liquid level pipe 2;

[0048] The liquid level pipe joint 3 is the liquid level pipe joint described in Embodiment 1.

[0049] Further, a plurality of the liquid level sensors 4 are arranged along the height direction of the liquid level pipe 2 .

[0050] The liquid level pipes 2 are arranged in parallel, so as to facilitate the installation of multiple liquid level sensors 4 in a limited space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com