Polyvinylidene fluoride filtering membrane as well as preparation method and application thereof

A polyvinylidene fluoride and filtration membrane technology, applied in the field of filtration, can solve the problems of small water contact angle and poor filtration performance, and achieve the effects of increasing water contact angle, enhancing oil filtration effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

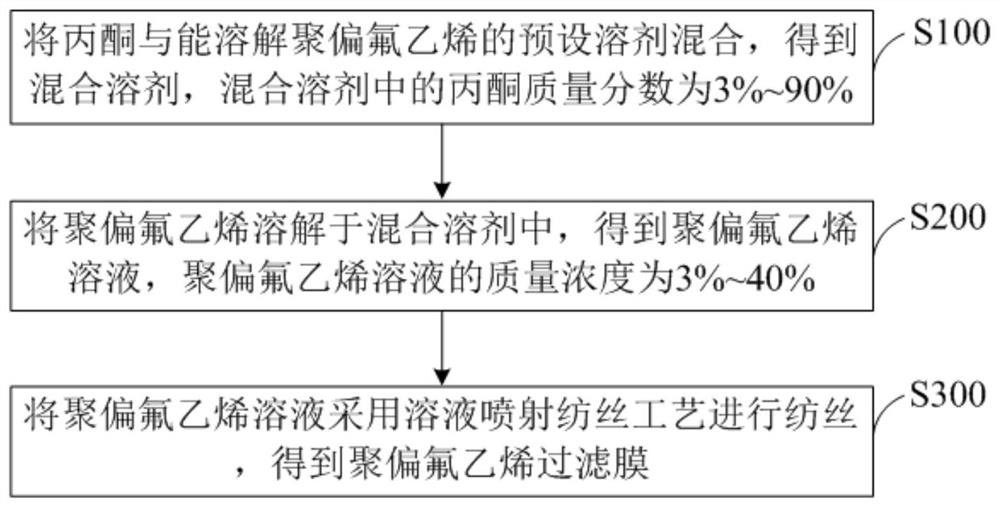

[0026] The embodiment of the present application provides a preparation method of a polyvinylidene fluoride filter membrane, such as figure 1 As shown, the preparation method of polyvinylidene fluoride filter membrane comprises the following steps:

[0027] S100, mixing acetone with a preset solvent capable of dissolving polyvinylidene fluoride to obtain a mixed solvent, and the mass fraction of acetone in the mixed solvent is 3% to 90%;

[0028] S200, dissolving polyvinylidene fluoride (ie PVDF) in a mixed solvent to obtain a polyvinylidene fluoride solution, and the mass concentration of the polyvinylidene fluoride solution is 3% to 40%;

[0029] S300, spinning the polyvinylidene fluoride solution by a solution jet spinning process to obtain a polyvinylidene fluoride filter membrane.

[0030] In the method for preparing a polyvinylidene fluoride filter membrane provided in the embodiment of the present application, a mixed solvent formed by mixing acetone and a preset solve...

Embodiment 1

[0045] A preparation method of polyvinylidene fluoride filter membrane comprises the following steps:

[0046] S101, uniformly mixing 7.5g DMF and 0.4g acetone to obtain a mixed solvent;

[0047] S102, adding 2.5 g of polyvinylidene fluoride to the mixed solvent, and stirring at a temperature of 60° C. at a speed of 800 rpm for 1 h to obtain a polyvinylidene fluoride solution:

[0048] S103, spinning the polyvinylidene fluoride solution by a solution jet spinning process to obtain a polyvinylidene fluoride filter membrane; during spinning, the distance between the spinneret and the receiver is 20cm, and the airflow velocity of the compressed air is 40m / s, the extrusion speed of the spinneret was 5 mL / h.

Embodiment 2

[0050] A preparation method of polyvinylidene fluoride filter membrane comprises the following steps:

[0051] S201, uniformly mixing 7.5g DMF and 0.6g acetone to obtain a mixed solvent;

[0052] S202, adding 2.5 g of polyvinylidene fluoride to the mixed solvent, and stirring at a temperature of 60° C. at a speed of 800 rpm for 1 h to obtain a polyvinylidene fluoride solution:

[0053] S203, spinning the polyvinylidene fluoride solution by a solution jet spinning process to obtain a polyvinylidene fluoride filter membrane; during spinning, the distance between the spinneret and the receiver is 20cm, and the airflow velocity of the compressed air is 40m / s, the extrusion speed of the spinneret was 5 mL / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com