Segmented discharge type flow-equalizing bag-type dust collector

A bag dust collector, discharge type technology, applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of bag filter dust removal performance reduction, unable to filter dust, unable to blow down dust, etc., to improve filter dust removal Ability, the effect of strengthening the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

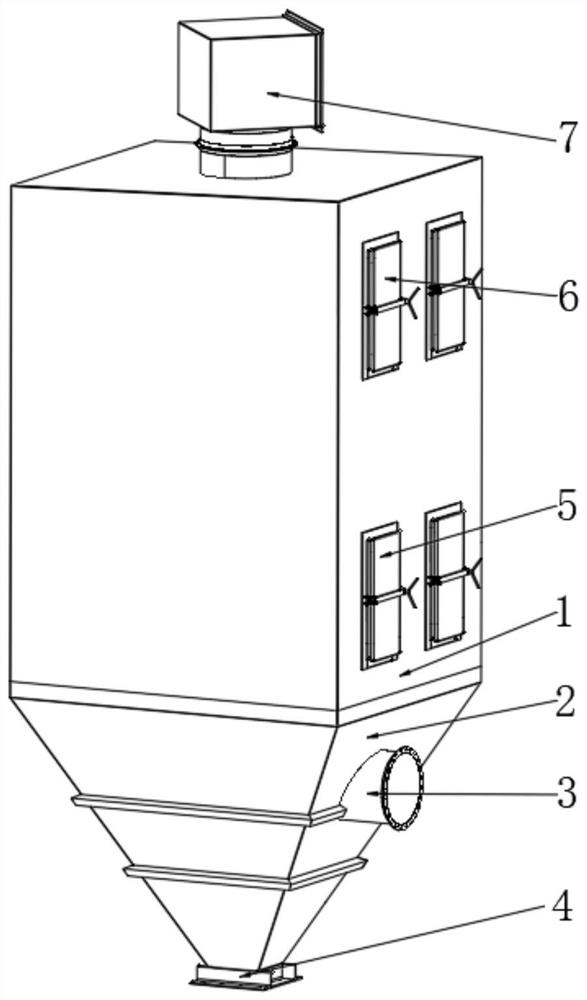

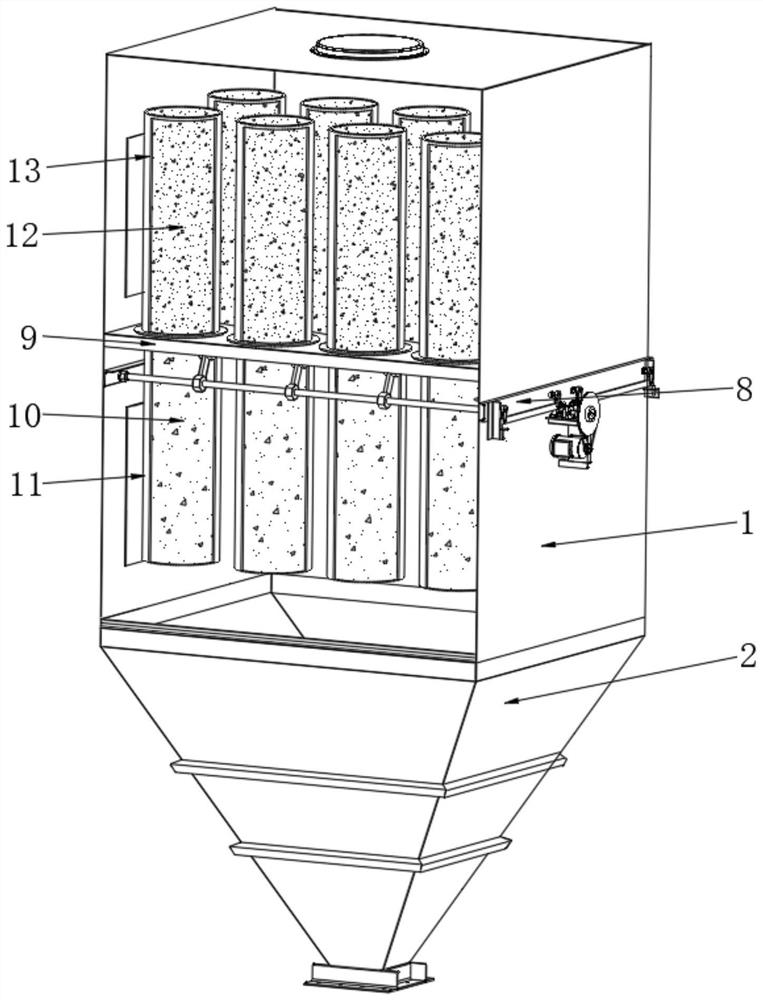

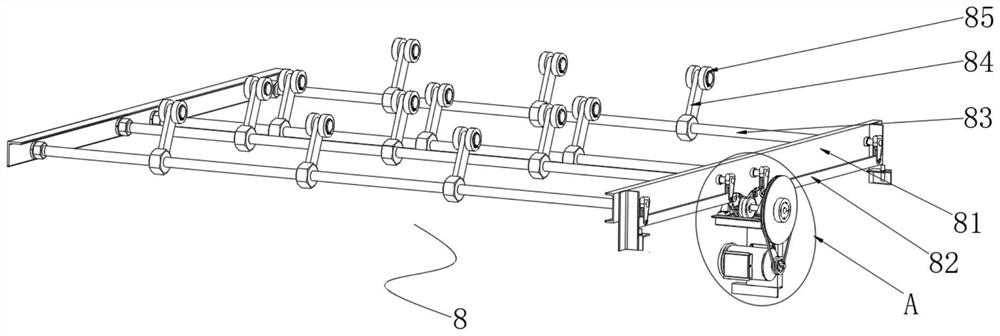

[0023] see Figures 1 to 6 , In the embodiment of the present invention, a segmented discharge type uniform flow bag filter includes a dust removal box 1, one side of the dust removal box 1 is located at the lower half position symmetrically connected with two sets of first access door panels 5, and the dust removal box Two sets of second access door panels 6 are symmetrically connected to one side of the 1 at the upper half position. During the use of the bag filter, by opening the first access door panel 5 and the second access door panel 6 on the side of the dust box 1, it can be It is convenient for staff to carry out regular maintenance work on its internal equipment.

[0024] The top of the dust box 1 is connected to the air outlet 7 at the middle position, and the bottom of the dust box 1 is connected to the ash box 2. One side of the ash box 2 is connected to the air inlet 3 at the middle position, and the ash material The bottom of the box 2 is located at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com