Composite filter cloth

A technology of composite filtration and filter cloth, which is applied in the field of filter cloth, can solve the problems of reducing the service life of filter bags, difficulty in filtering out dust particles, increasing the breakage rate of filter bags, etc., and achieves long service life, enhanced strength, and is not easy to clog Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to better understand the present invention, the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

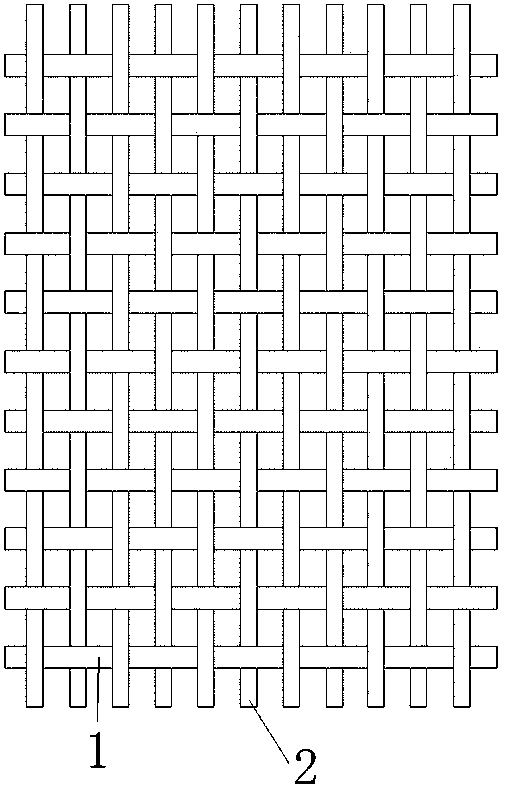

[0012] Such as figure 1 As shown, a composite filter cloth filter cloth is made of several warp threads 2 and weft threads 1. The warp threads 2 are Wuyan fibers, and the weft threads 1 are polypropylene tearing membranes; Vinyl fluoride filter membrane; the filter cloth and the filter membrane are combined by hot pressing to form an integral structure.

[0013] The filter cloth also includes a base cloth. The base cloth is a woven fabric formed by weaving yarns. The base cloth and the filter cloth are connected by lamination to form an integral structure. The base cloth includes a polyester fiber non-woven fabric. The thickness of the filter cloth is 0.16 mm.

[0014] The present invention is not limited to the specific implementation manners described above. The above descriptions are only pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com