Method for estimating optimal energy protein ratio and feed

An energy-to-protein ratio, the best technology, applied in animal feed, animal feed, equipment, etc., can solve the problems of low feed conversion efficiency, waste of protein feed resources, low feed conversion rate, etc., to avoid excessive accumulation of abdominal fat, avoid The effect of low protein biological titer and feed conversion efficiency and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

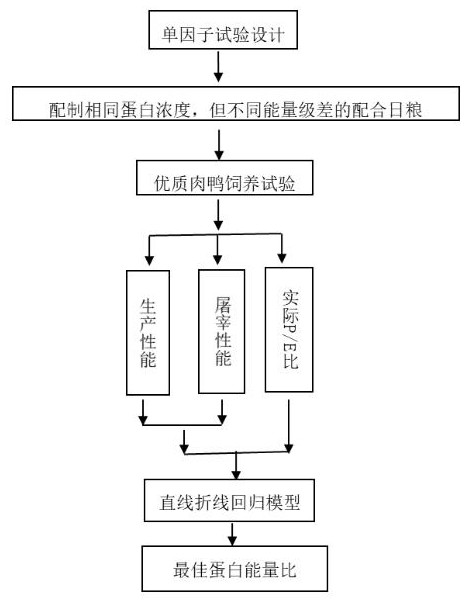

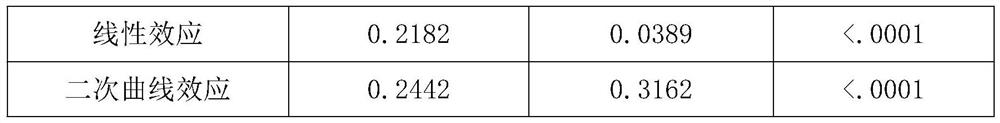

[0024] Example 1: Using a single-factor completely randomized experimental design, with a corn-soybean meal basal diet, when the crude protein was 19.55%, the effect of dietary metabolizable energy concentration of three ear ducks on the actual energy and protein of three ear ducks 0-4 weeks old was studied. The results are shown in Table 1: with the increase of dietary AME level, energy intake and protein intake had no significant effect (P>0.05), but protein intake showed a linear increase trend (P <0.05), the calculation found that with the increase of dietary AME level, the actual intake of energy to protein ratio increased linearly (P < 0.05) and quadratic curve model (P < 0.05), the above results indicate that dietary energy Concentration regulates the ingested energy-to-protein ratio.

[0025] Table 1: Effects of dietary metabolizable energy concentration of Sansui ducks on energy and protein intake of 0-4 weeks old Sansui ducks

[0026]

[0027]

Embodiment 2

[0028]Example 2: The ingested energy-to-protein ratio was regulated by the feed energy concentration. It was found that with the increase of the energy-to-protein ratio, the final weight and the average daily increment increased linearly (P2 = 0.88). The regression relationship between the energy-to-egg ratio and the average daily weight gain was fitted by a straight-line broken line model. The results showed that when the energy-to-egg ratio was 13.96 (kcal / g) (ie CP=19.55%, AME=2729.2kcal / kg), the curve reached the lowest The inflection point, the inflection point is 25.06 (g / g), that is, the best daily gain is 25.06C. The fitted curve is y=25.06-5.6607*(13.9559-x), P=0.0439, R 2 = 0.86).

[0029] Table 2: Effects of energy-protein ratio of Sansui ducks on the production performance of 0-4 weeks old Sansui ducks

[0030]

Embodiment 3

[0031] Example 3: The ingested energy-to-protein ratio was regulated by the energy concentration of the feed. It was found that with the increase of the energy-to-protein ratio, the abdominal fat rate increased linearly (P2 =0.87). When the energy-to-protein specific energy-to-egg ratio was 14.96 (kcal / g), it did not affect the production of chest and leg muscles.

[0032] Table 3: Effects of energy-protein ratio of Sansui ducks on slaughter performance of 0-4 weeks old Sansui ducks

[0033] Energy to egg ratio (kcal / g) Leg muscle rate / % Chest muscle rate / % gizzard index / % Abdominal fat rate / % Liver body rate / % 13.35 10.55 1.33 5.06 0.223c 2.11 13.91 11.54 1.39 3.92 0.359bc 1.93 14.42 10.87 1.53 4.25 0.437b 2.04 14.99 10.59 1.22 4.67 0.524ba 1.98 15.50 10.43 1.50 4.16 0.491ba 1.95 16.06 10.48 1.46 4.92 0.646a 2.00 aggregate standard error 0.14 0.05 0.17 0.03 0.04 AME effect 0.1547 0.58...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com