Storage equipment for recycling waste lead-acid storage battery and use method thereof

A lead-acid battery, waste technology, used in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of low storage space utilization, small storage area, high space utilization, and achieve installation and maintenance. Convenience, small storage footprint, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

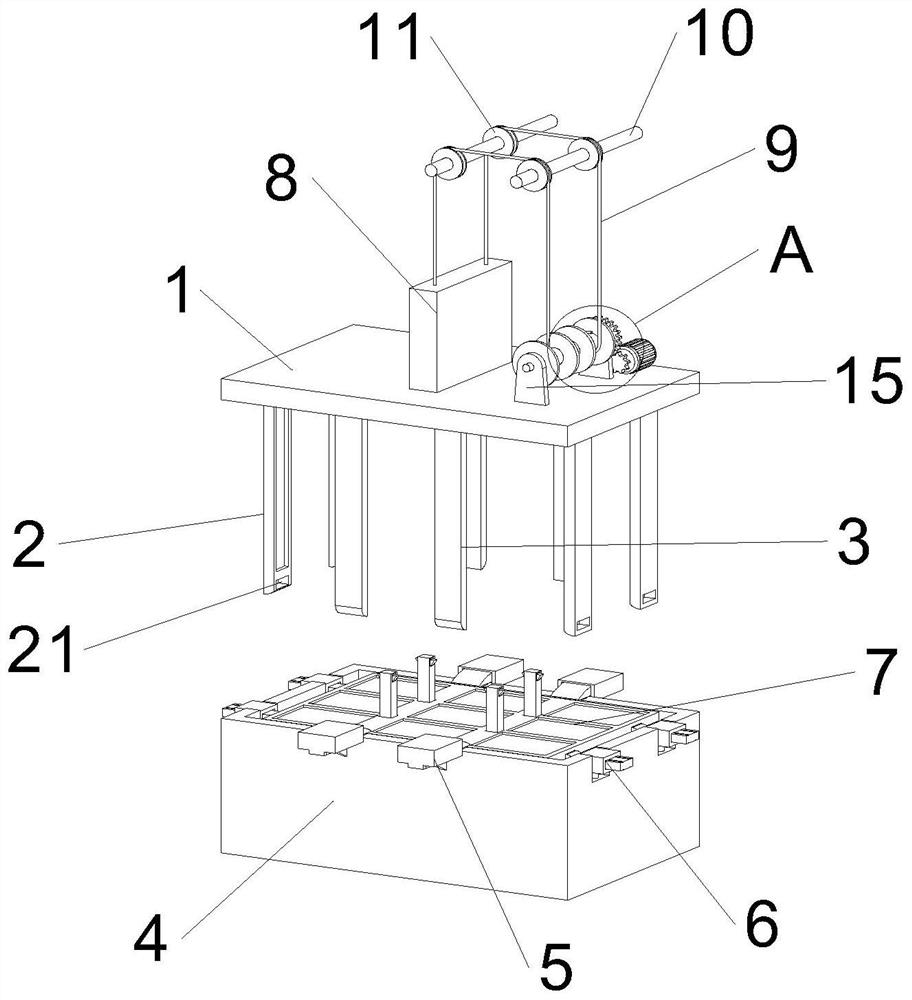

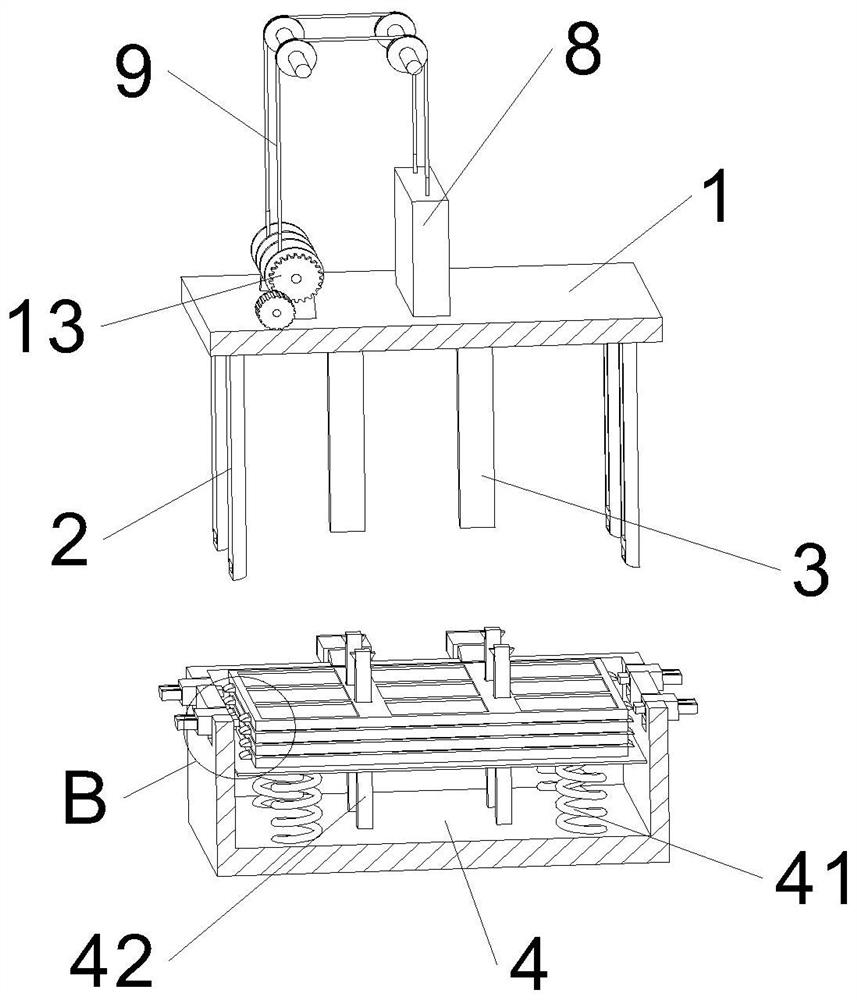

[0040] see figure 1 - Figure 7 As shown, a storage device for recycling waste lead-acid batteries includes a cover plate 1, a connecting block 8 is fixedly connected above the cover plate 1, a lifting cable 9 is fixedly connected to the top of the connecting block 8, and the lifting cable 9 is wound around the runner 11 Externally, the runner 11 is rotatably connected to the outer wall of the fixed rod 10, so that the runner 11 can adjust the length of the hoisting cables 9 located on both sides of the fixed rod 10 through rotation, so that the cover plate 1 is kept balanced;

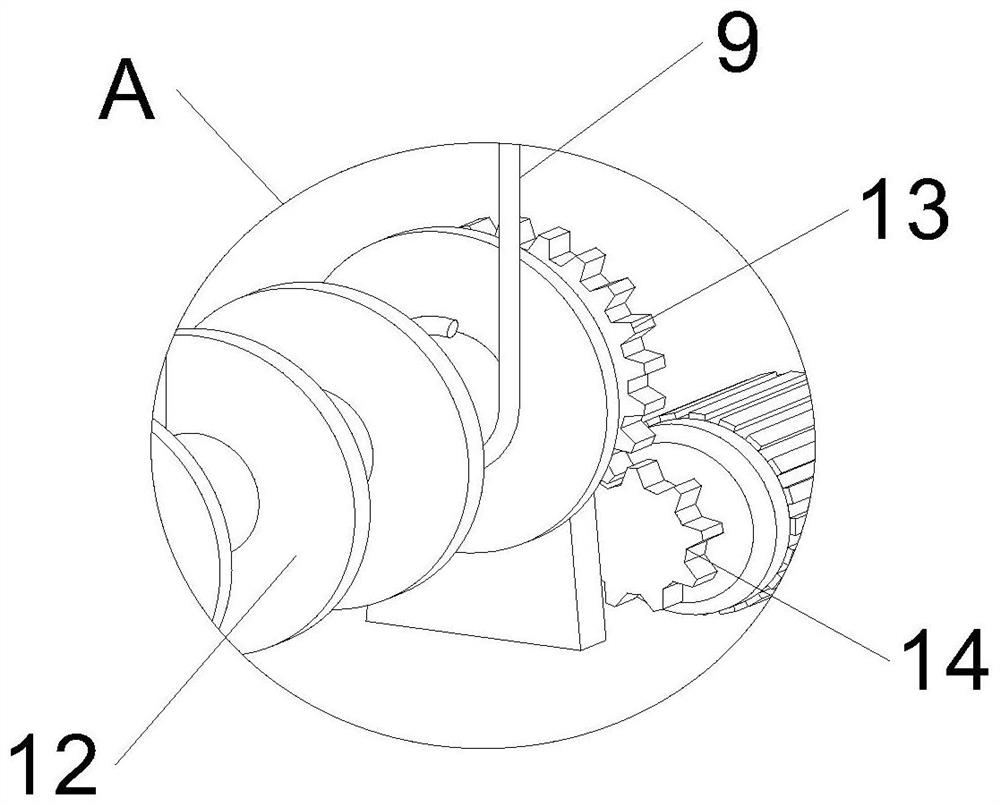

[0041] One end of the hoisting cable 9 away from the connecting block 8 is fixedly connected to the outer wall of the reel 12, and the elongation or shortening of the hoisting cable 9 is controlled by the rotation of the reel 12. One end of the reel 12 is fixedly connected with a transmission gear 13, The gear 13 drives the winding wheel 12 to rotate, and the two ends of the winding wheel 12 are conne...

Embodiment 2

[0043] see Figure 8 - Figure 11 As shown, the top of the storage box 4 is fixedly connected to the limit box 5, the limit box 5 is fixedly connected to the limit spring 51 inside, the outer end of the limit spring 51 is fixedly connected to the limit pin 52, and the limit pin 52 is slidably connected to the limit spring 51. Inside, the lower surface of the limit pin 52 abuts on the upper surface of the pallet 7, when the support spring 41 pushes the pallet 7 upward, the limit pin 52 restricts the pallet 7 to always be in the position on the surface of the storage box 4, and the limit The upper surface of the pin 52 is a wedge-shaped arc surface, so that the limit pin 52 can be pushed open when the insertion rod 3 falls, so that the support plate 7 can be lifted, and the storage box 4 is provided with a position close to the limit box 5 for the insertion rod 3 to enter. The groove provides a space for the insertion rod 3 to enter. The placement slot 21 at the bottom of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com