Retroreflective sheet and preparation method thereof

A retro-reflective and reflective layer technology, applied in the direction of instruments, vehicle parts, printing, etc., can solve the problems of easy stickiness of reflective film, high pressure of winding core, falling off, etc., and achieve good wipeability, high production efficiency and convenient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

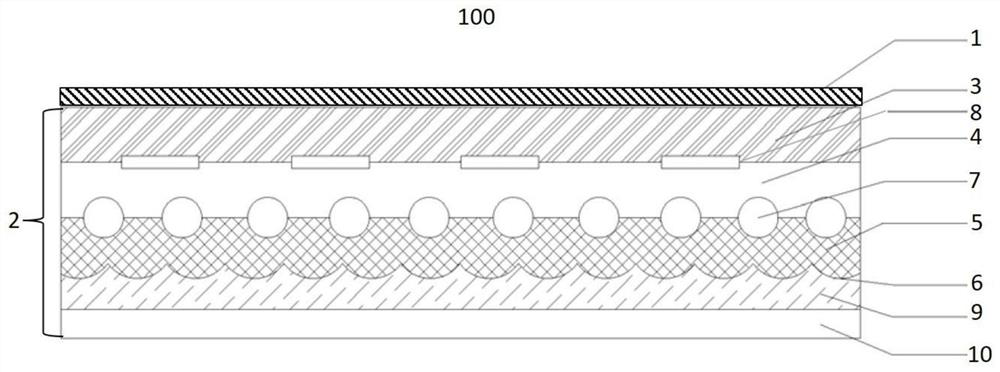

[0071]

[0072] The present invention also provides the preparation method of the retroreflective sheet of the present invention, which comprises the following steps: printing ink on the surface of the reflective layer body containing glass microbeads arranged in a roll, and then drying at a temperature below 95°C, and the drying time is 40°C. seconds or more. If the temperature is above 95°C, the release paper will be defective due to the evaporation of moisture in the release paper. In some embodiments of the present invention, the drying time is 50 to 150 seconds in consideration of printability, drying and economy.

[0073] In some specific embodiments of the present invention, the thickness of the reflective layer body containing glass microbeads arranged in a roll is 100-500 μm. Further, the thickness is 120-400 μm, further 150-300 μm, in some specific embodiments of the present invention, the thickness of the reflective layer body 2 after removing the release layer i...

Embodiment 1

[0083] Preparation of the glass microbead-containing light-reflecting layer body: As the engineering substrate, a transparent polyethylene terephthalate film with a thickness of 75 μm (trade name: Teijin Tetoron Film S-75) manufactured by Teijin Co., Ltd. was used. Then, a methylated melamine resin solution (trade name: NIKALAC MS-11) manufactured by SANWACHEMICAL CO., LTD. was added to 100 parts by weight of an acrylic resin solution (trade name: RS-1200) manufactured by SANWACHEMICAL CO., LTD. 16 parts by weight, 6 parts by weight of a cellulose derivative (trade name: CAB) manufactured by TOKUSHIKI Co., Ltd., 1.5 parts by weight of an ultraviolet absorber (trade name: Seesorb 103) manufactured by SHIPRO KASEIKAISHA, LTD, BYK-Chemie Japan KK 0.05 parts by weight of a prepared leveling agent (trade name: BYK-300), 0.12 part by weight of a catalyst (trade name: BECKAMINE P-198) manufactured by DIC Co., Ltd., and 16.7 in a ratio of MIBK / toluene=8 / 2 as a solvent The resin mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com