Grinding wheel sand blasting hardness machine

A hardness machine and sand blasting technology, which is applied in the direction of testing material hardness, strength characteristics, instruments, etc., can solve the problems of hardened materials that are not broken up, cannot be guaranteed, hardened, etc., and achieve the effect of ensuring the hardness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

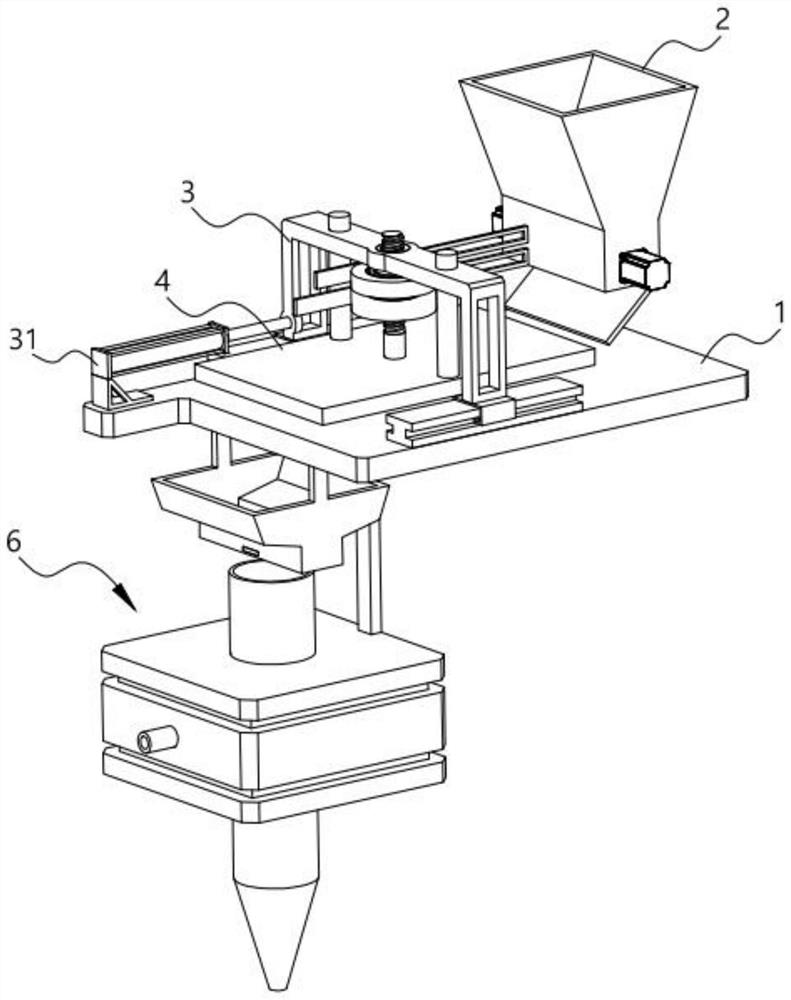

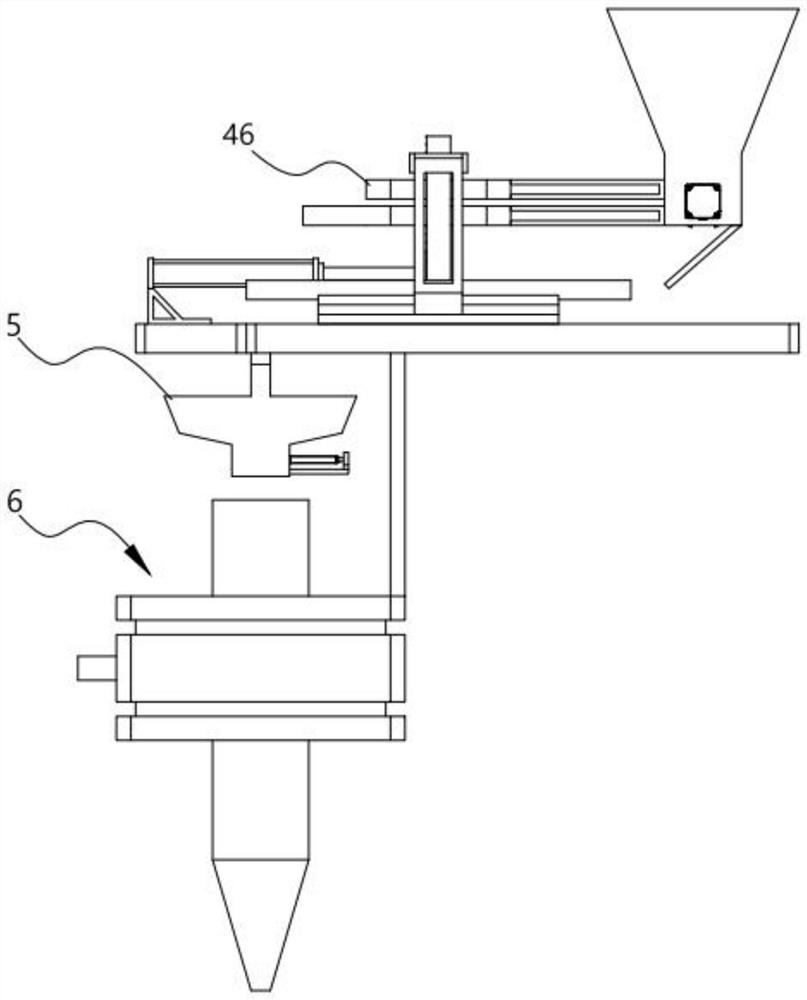

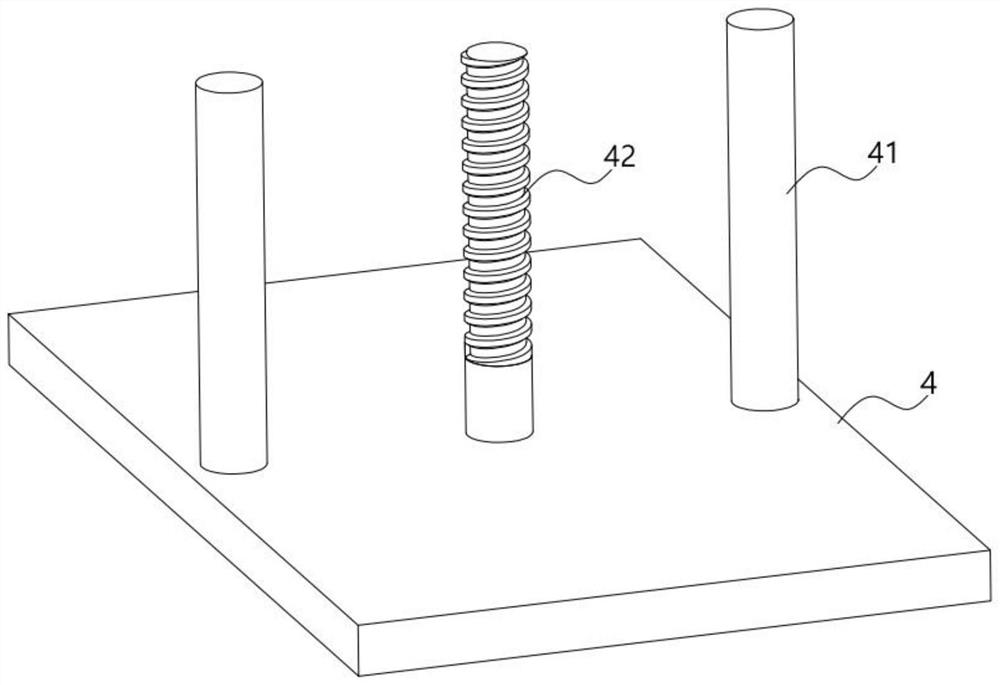

[0028] see Figure 1 to Figure 7 , the present invention provides a kind of technical scheme:

[0029] A grinding wheel sandblasting hardness machine, including a lower extrusion plate 1, a hopper 2, a support frame 3, an upper extrusion plate 4, a weighing hopper 5 and a sandblasting assembly 6, the hopper 2 is arranged on the lower extrusion plate 1, wherein the hopper The bottom of 2 is equipped with a quantitative blanking component for quantitative blanking, and the material in the hopper 2 will enter between the lower extrusion plate 1 and the upper extrusion plate 4, and the quantitative blanking here can effectively avoid material accumulation case where:

[0030] The support frame 3 is arranged on the lower extrusion plate 1 through a linear guide pair, wherein the linear guide pair is a linear guide rail set on the lower extrusion plate 1 and a slider fitted on the linear guide rail, wherein the support frame 3 is connected with the linear slider. The connection be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com