Efficient edge banding machine for PVC foam board

An edge banding machine and foam board technology, which is applied to machine tools, grinders, metal processing and other directions suitable for grinding the edge of workpieces, can solve the problems of poor edge banding effect and low edge banding efficiency, and achieves the solution of edge banding efficiency. Low, improve efficiency, prevent the effect of sheet jumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

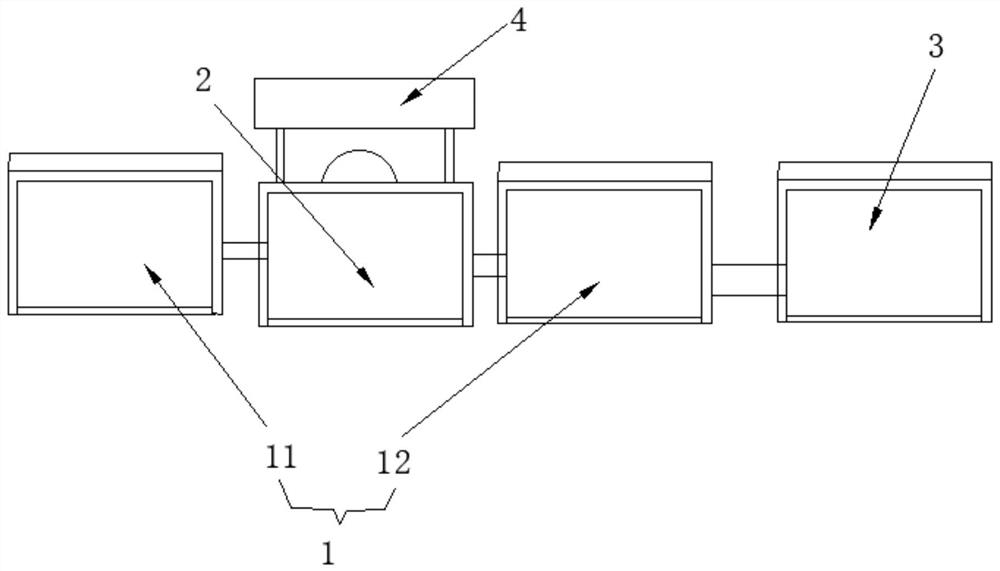

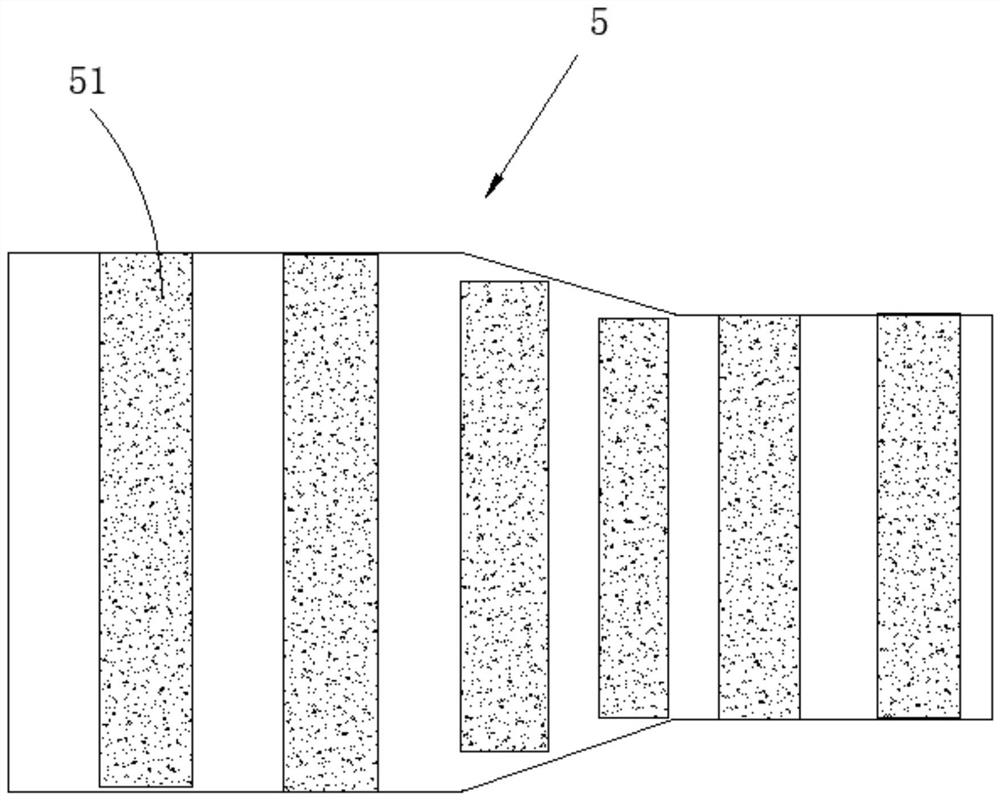

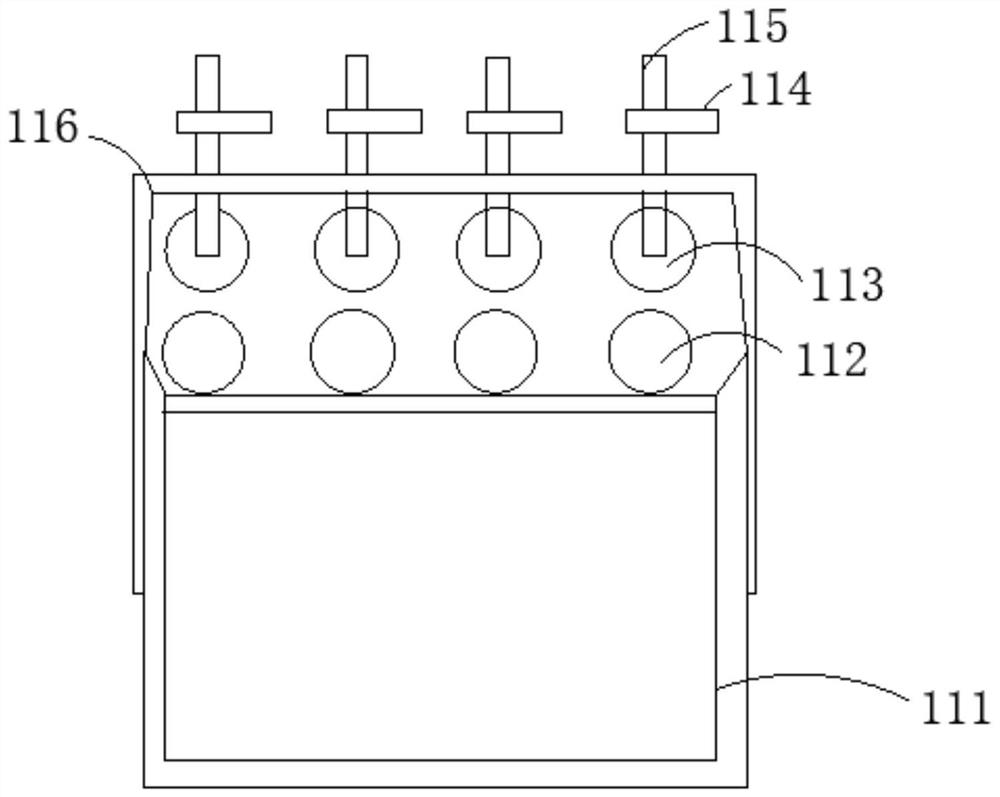

[0025] see figure 1 and Figure 5 , Embodiment 1 of the present invention provides a high-efficiency edge banding machine for PVC foam boards, including a conveying mechanism 1, a pressing mechanism 4, and an edge-sealing saw mechanism; the conveying mechanism 1 includes a feed assembly 11 and a discharge assembly 12. The edge banding saw mechanism 2 is arranged between the feeding assembly 11 and the output assembly 12, and the edge banding saw mechanism 2 includes an edge banding saw bracket and a saw blade set on the edge banding saw bracket Assemblies, the saw blade assembly includes a high steel saw blade 23, the inclination of the high steel saw blade 23 is 30 degrees; the edge banding saw mechanism 2 also includes a control module for controlling the high steel saw blade 23 The rotation speed; the pressing mechanism 4 includes a pressing assembly and a positioning module for positioning and pressing the plate 39 .

[0026] see Figure 5 It should be noted that the po...

Embodiment 2

[0029] Implementation 2 On the basis of implementation 1, the structure of the high-efficiency edge banding machine for PVC foam board is described in detail.

[0030] see figure 1 and Figure 5 , a high-efficiency edge banding machine for PVC foam boards, including a conveying mechanism 1, a pressing mechanism 4, and an edge-sealing saw mechanism 2; the conveying mechanism 1 includes a feed assembly 11 and a discharge assembly 12; the edge-sealing saw The mechanism 2 is arranged between the feed assembly 11 and the discharge assembly 12. The edge banding saw mechanism 2 includes an edge banding saw bracket and a saw blade assembly arranged on the edge banding saw bracket. The saw blade assembly Including a high-steel saw blade 23, the inclination of the high-steel saw blade 23 is 30 degrees; the edge banding saw mechanism 2 also includes a control module for controlling the rotating speed of the high-steel saw blade 23; the pressing The mechanism 4 includes a pressing assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com