Soft, tender and smooth block silicone oil for cotton and preparation method thereof

A technology of block silicone oil and soft cotton, which can be used in fiber treatment, textiles and papermaking, etc. It can solve the problems that can not be solved, and achieve the effect of improving anti-yellowing property, increasing polarity and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

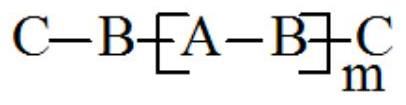

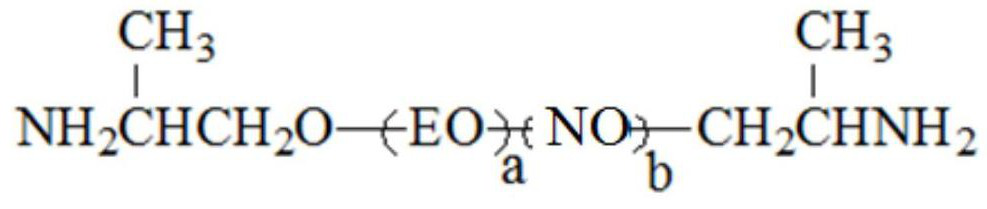

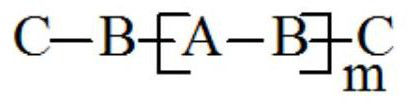

Method used

Image

Examples

Embodiment 1

[0041] Mix 20g epoxy double cap, 490g organosiloxane ring (DMC) and 35g N,N-dimethylacetamide evenly, add 0.1g (CH 3 ) 4 NOH (added in the form of alkali glue), heated to 100°C, equilibrated for 8h; then heated to about 140°C to decompose the catalyst for 2h, and distilled under reduced pressure to remove the solvent and low boilers to obtain a colorless or pale yellow terminated epoxy silicone oil;

[0042]Mix 7.15g of glycidyl acetate and 40g of ethylene oxide evenly, add 0.0295g of Lewis acid catalyst, and obtain a polyether polyol containing acetate in the side chain by addition polymerization, and a polyether polyol of acetate Alcohols are subjected to aminolysis to obtain acetate-containing polyetheramines in their side chains.

[0043] The epoxy-terminated silicone oil obtained in the previous step, 44.5 g of polyetheramine containing acetate in the side chain (molecular weight of 900) and 370 g of isopropanol were mixed uniformly, and reacted at 75 ° C for 15 h to ob...

Embodiment 2

[0046] Mix 30g epoxy double cap, 915g organosiloxane ring (DMC) and 60g N,N-dimethylacetamide evenly, add 0.2g (CH 3 ) 4 NOH (added in the form of alkali glue), heated to 100°C, equilibrated for 8h; then heated to about 140°C to decompose the catalyst for 2h, and distilled under reduced pressure to remove the solvent and low boilers to obtain a colorless or pale yellow terminated epoxy silicone oil;

[0047] Mix 9.5g of glycidyl acetate and 61g of ethylene oxide evenly, add 0.042g of Lewis acid catalyst, and obtain polyether polyol containing acetate in side chain, polyether polyol of acetate through polyaddition reaction Alcohols are subjected to aminolysis to obtain acetate-containing polyetheramines in their side chains.

[0048] The terminal epoxy silicone oil obtained in the previous step, 67g of polyetheramine containing acetate in the side chain (molecular weight of 900) and 675g of isopropanol were mixed uniformly, and reacted at 75°C for 15h to obtain the block poly...

Embodiment 3

[0051] Mix 20g epoxy double cap, 735g organosiloxane ring (DMC) and 50g N,N-dimethylacetamide evenly, add 0.15g (CH 3 ) 4 NOH (added in the form of alkali glue), heated to 100°C, equilibrated for 8h; then heated to about 140°C to decompose the catalyst for 2h, and distilled under reduced pressure to remove the solvent and low boilers to obtain a colorless or pale yellow terminated epoxy silicone oil;

[0052] Mix 18.3g of glycidyl acetate and 88g of ethylene oxide evenly, add 0.07g of Lewis acid catalyst, and obtain a polyether polyol containing acetate in the side chain through addition polymerization, and a polyether polyol of acetate Alcohols are subjected to aminolysis to obtain acetate-containing polyetheramines in their side chains.

[0053] The epoxy-terminated silicone oil obtained in the previous step, 99.5 g of polyetheramine containing acetate in the side chain (molecular weight of 2000), 700 g of isopropanol and 350 g of ethylene glycol monobutyl ether were mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com