Monocrystalline silicon wafer texturing equipment

A technology for monocrystalline silicon wafers and crystalline silicon wafers, which is applied in the field of monocrystalline silicon wafer texturing equipment, can solve problems such as differences in the etching degree of crystalline silicon wafers, uniform concentration of the overall texturing tank, and differences in reflectivity of crystalline silicon wafers, etc., to achieve Response time is consistent and the effect of solving the difference in reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

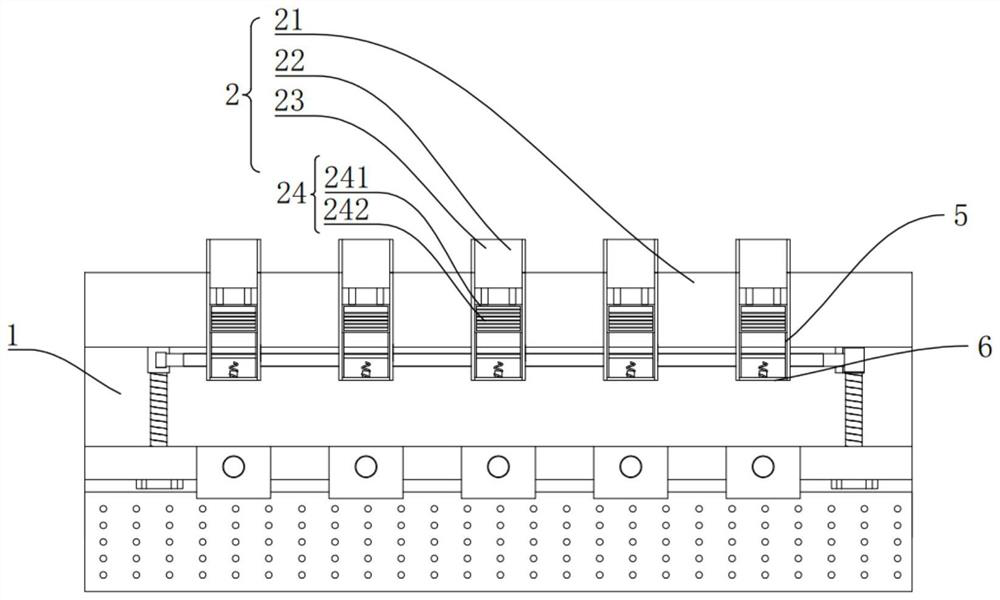

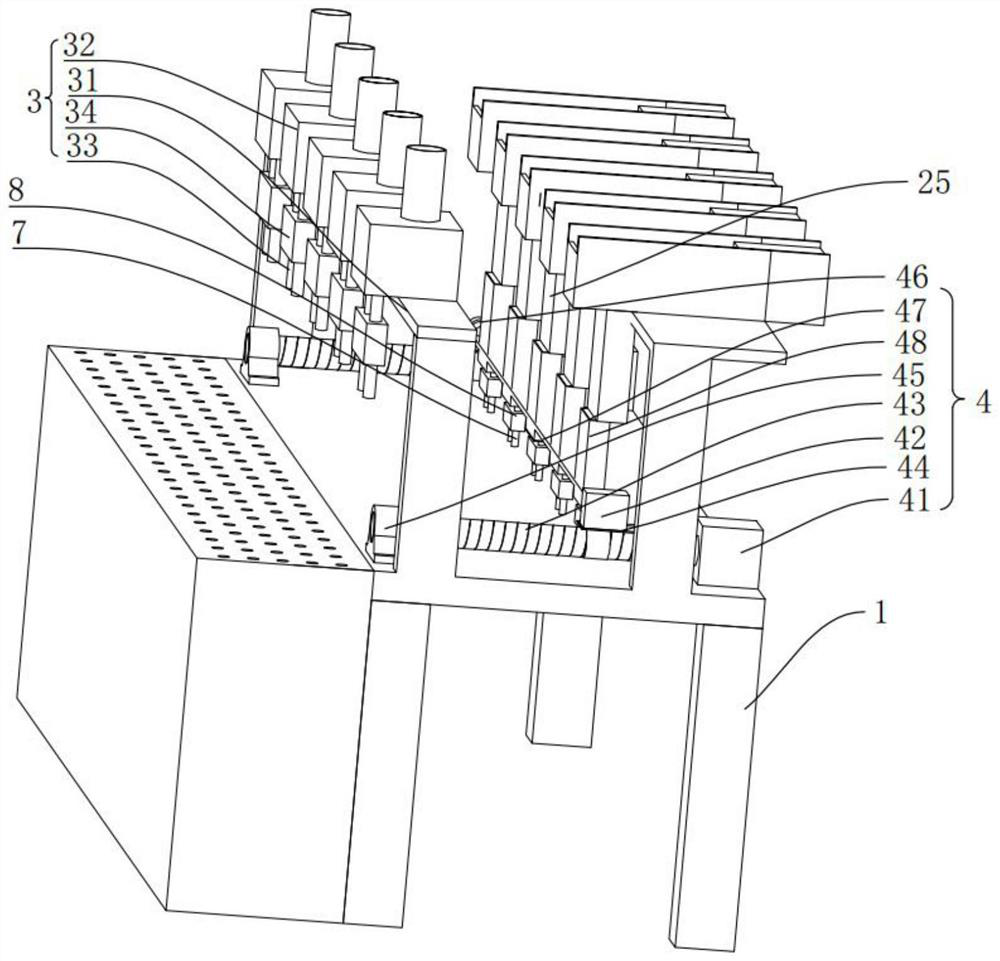

[0040] like Figure 1-2 As shown, a single crystal silicon wafer texturing equipment includes a workbench 1, and the workbench 1 is provided with a feeding device 2 for supplying silicon wafers, a liquid supply device 3 for providing texturing silicon wafers, and a feeding device for making silicon wafers. The reaction device 4 for the texturing reaction. After the feeding device 2 sends the crystalline silicon wafer to the reaction device 4, the liquid supply device 3 sends the texturing liquid to the reaction device 4. Tablets and texturing liquid are poured out for next use.

[0041]The crystalline silicon wafers to be processed are placed in the feeding device 2, the feeding device 2 feeds the crystalline silicon wafers individually into the reaction device 4, the reaction device 4 is moved to the lower part of the liquid supply device 3, and the liquid supply device 3 injects the system into the generating device. In the texturing liquid, the crystalline silicon wafer un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com