Noctilucent aerosol paint and preparation method thereof

A technology of phosgene and luminous powder, which is applied in the direction of luminescent paint, reflective/signal paint, coating, etc., which can solve the problems of many construction steps, difficult construction, and short luminous time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

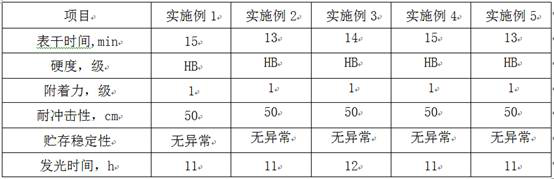

Examples

Embodiment 1

[0038] By weight, mix 12 parts of Minghui MHG-4C luminous powder, 2 parts of nano graphite powder, 3 parts of 150-500 mesh total reflection glass beads, dehydrate and cool down, add 2 parts of 3-aminopropyltriethoxysilane and mix well, 30 parts of hydroxyl-modified acrylic resin, 12 parts of Miki Chemical SM1046, 18 parts of propylene glycol, 5 parts of DeuRheo 211P, 0.5 parts of EFKA FL3740, 0.5 parts of EFKA-3034, and mixed to prepare a liquid material; the liquid material is divided into aerosols The can is sealed and filled with 15 parts of HFC-134a according to the specified weight proportion, and the finished product is obtained by packaging.

Embodiment 2

[0040] In proportion by weight, 14 parts of Minghui MHG-4D luminous powder, 4 parts of nano graphite powder, 4 parts of 150-500 mesh total reflection glass beads were dehydrated and cooled, and 1.9 parts of 3-aminopropyltriethoxysilane was added and stirred well. 16 parts of styrene-modified acrylic resin, 15 parts of styrene-butadiene-modified acrylic resin, 12 parts of Miki Chemical SM1046D, 2 parts of isopropyl alcohol, 10 parts of ethylene glycol monobutyl ether, 2 parts of DeuRheo 211F, THIXATROL P220X 3 0.2 part of EFKA FL3745, 0.1 part of EFKA FL3939, 0.1 part of Borchi GOL LA200, 0.1 part of Borchi GOL LA2, 0.3 part of EFKA SI 2741, 20.1 part of Borchi GEN12539, 0.2 part of Borchi GEN1015 and mixed to prepare a feed liquid; Fill an aerosol can and seal it, fill it with 10 parts of HFC-152a, 3 parts of cyclopentane and 2 parts of n-pentane according to the prescribed weight proportion, and package to obtain the finished product.

Embodiment 3

[0042] In proportion by weight, 10 parts of Minghui MHG-4C, 4 parts of Minghui MHG-4C, 2.8 parts of nano graphite powder, 3.5 parts of 150-500 mesh total reflection glass beads were dehydrated and cooled, and 3-aminopropyltriethoxy was added. 0.5 part of silane, 0.5 part of N-2-aminoethyl-3-aminopropyltrimethoxysilane, 0.5 part of N-2-aminoethyl-3-aminopropylmethyldimethoxysilane, stir well, benzene 16 parts of ethylene modified acrylic resin, 16 parts of styrene butadiene modified acrylic resin, 5 parts of Miki Chemical SM1046, 7 parts of Miki Chemical SM1046D, 4 parts of propylene glycol, 4 parts of isopropyl alcohol, 4 parts of ethylene glycol monobutyl ether, 2 parts of DeuRheo 211P, 2 parts of DeuRheo 211F, 1 part of THIXATROL P220X, 0.1 part of EFKA FL3740, 0.1 part of EFKA FL3741, 0.1 part of EFKA FL3745, 0.3 part of Borchi GEN1252, 0.1 part of Borchi GEN1015; The aerosol can is sealed and filled with 14 parts of cyclopentane and 2.6 parts of n-pentane according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com