Acid-modified ultrathin metal organic framework nanosheet catalyst as well as preparation method and application thereof

An ultra-thin metal and organic framework technology, applied in electrolytic components, electrodes, electrolytic processes, etc., can solve the problems of poor electrocatalytic performance, insufficient stability, and instability, and achieve good catalytic stability, low cost, and low cost. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

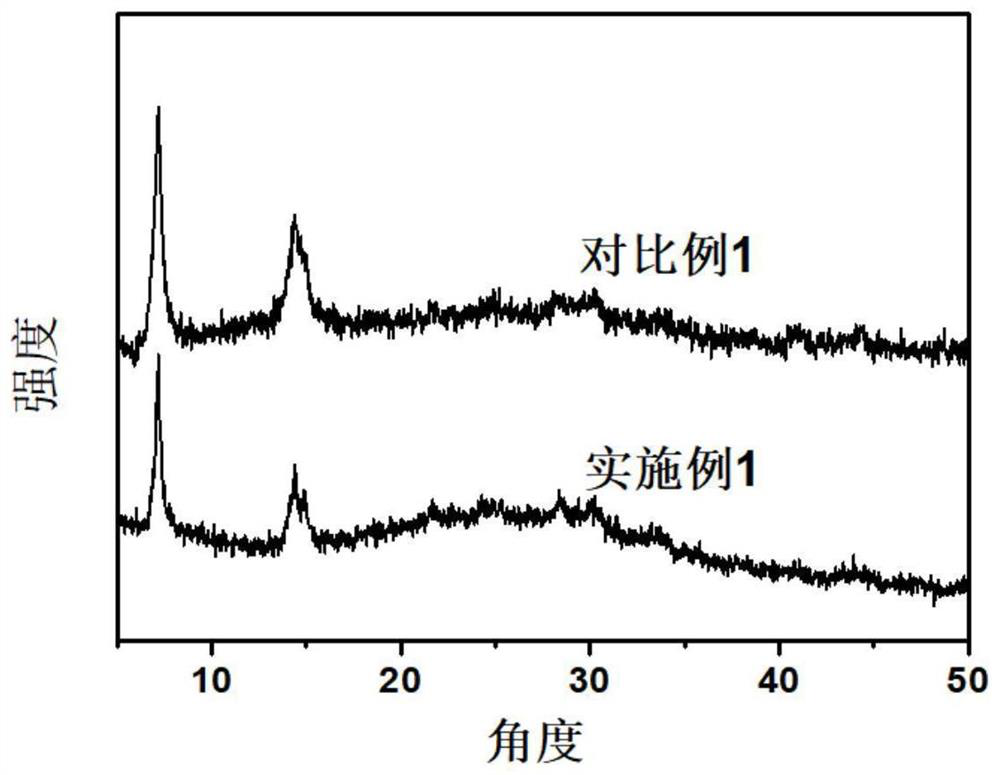

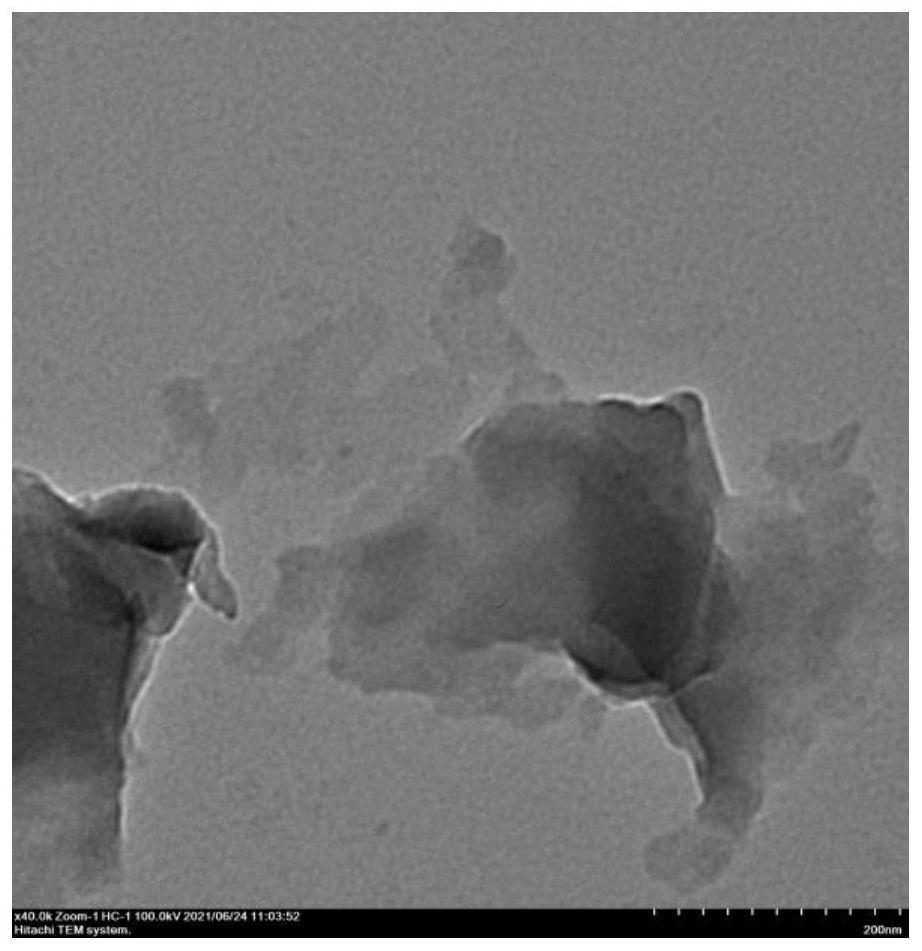

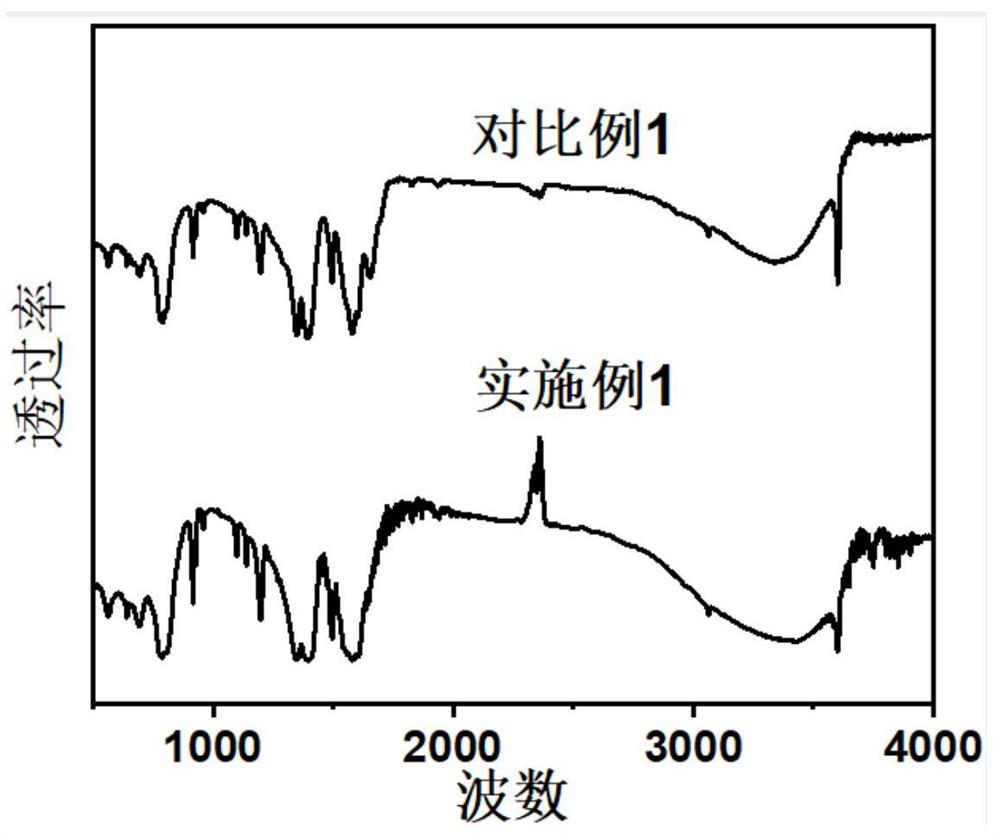

Embodiment 1

[0048] 216.2 mg of 2,6-naphthalenedicarboxylic acid was added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32 mL: 2 mL: 2 mL), followed by adding 190.2 mg of hexanaphthene to the above solution. Nickel chloride in water, 1.0 mL of triethylamine was added rapidly at the same time, and magnetic stirring was performed for 10 min. Then, the above mixed solution was transferred to an ultrasonic crusher, and the intensity of 400W was used for ultrasonic peeling for 300min. After the peeling was completed, it was washed several times with absolute ethanol, and the solid samples were separated with a high-speed centrifuge at 10000r / s. The solid sample was then added to 1 mmol L -1 In acetic acid, treated with acid for 1 h, washed several times with absolute ethanol after peeling, and separated the solid sample with a high-speed centrifuge at 10,000 r / s, and finally dried the sample in vacuum at room temperature for 12 h.

Embodiment 2

[0050] 216.2 mg of 2,6-naphthalenedicarboxylic acid was added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32 mL: 2 mL: 2 mL), followed by adding 190.2 mg of hexanaphthene to the above solution. Nickel chloride in water, 1.0 mL of triethylamine was added rapidly at the same time, and magnetic stirring was performed for 10 min. Then, the above mixed solution was transferred to an ultrasonic crusher, and the intensity of 400W was used for ultrasonic peeling for 300min. After the peeling was completed, it was washed several times with absolute ethanol, and the solid samples were separated with a high-speed centrifuge at 10000r / s. The solid sample was then added to 0.5 mmol L -1 In acetic acid, treated with acid for 1 h, washed several times with absolute ethanol after peeling, and separated the solid sample with a high-speed centrifuge at 10,000 r / s, and finally dried the sample in vacuum at room temperature for 12 h.

Embodiment 3

[0052] 216.2 mg of 2,6-naphthalenedicarboxylic acid was added to a mixed solution of N,N-dimethylformamide, absolute ethanol and deionized water (32 mL: 2 mL: 2 mL), followed by adding 190.2 mg of hexanaphthene to the above solution. Nickel chloride in water, 1.0 mL of triethylamine was added rapidly at the same time, and magnetic stirring was performed for 10 min. Then, the above mixed solution was transferred to an ultrasonic crusher, and the intensity of 400W was used for ultrasonic peeling for 300min. After the peeling was completed, it was washed several times with absolute ethanol, and the solid samples were separated with a high-speed centrifuge at 10000r / s. The solid sample was then added to 1.5 mmol L -1 In acetic acid, treated with acid for 1 h, washed several times with absolute ethanol after peeling, and separated the solid sample with a high-speed centrifuge at 10,000 r / s, and finally dried the sample in vacuum at room temperature for 12 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com