Single-component polyurethane foam joint mixture and preparation method thereof

A technology of polyurethane foam and caulking agent, which is applied in the fields of layering/coating fertilizer, application, agriculture, etc., can solve the problems such as degradability and fertilization that are not mentioned, and improve the utilization rate of fertilizer and storage stability. good, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

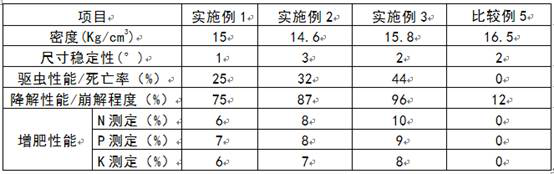

Examples

Embodiment 1

[0036] A one-component polyurethane foam gap filler, which is composed of the following components in parts by weight:

[0037] Polyether polyol Softcel U-1000 3 parts

[0038] Polyether polyol Arcol 1150 6 parts

[0039] Polytetrahydrofuran glycol PolyTHF 250 6 parts

[0040] Silicone oil DC5357 0.4 parts

[0041] Silicone oil DC5564 0.5 part

[0042] Silicone oil DC5598 0.5 part

[0043] Eco-friendly paraffin 14 parts

[0044] 0.3 part of bismorpholinyl diethyl ether

[0045] 1,4 dimethylpiperazine 0.3 part

[0046] Deltamethrin 0.5 part

[0047] Permethrin 0.5 part

[0048] Camphor 0.5 servings

[0049] Marigold 0.5 servings

[0050] Plastic additive DCP596 1 part

[0051] Plastic additive DCP542 1 part

[0052] Urea formaldehyde 0.5 part

[0053] Ammonium polyphosphate 0.5 part

[0054] Potassium polyphosphate 0.5 part

[0055] Photochromic powder MC12# 0.5 parts

[0056] Polymerized MDI 38 parts

[0057] HFC-245fa 5 servings

[0058] HFC-1234 9 copies

...

Embodiment 2

[0063] A one-component polyurethane foam gap filler, which is composed of the following components in parts by weight:

[0064] Polyether polyol Softcel U-1000 4 parts

[0065] Polyether polyol Arcol 1150 7 parts

[0066] Polytetrahydrofuran glycol PolyTHF 250 7.5 parts

[0067] Silicone oil DC5357 0.8 parts

[0068] Silicone oil DC5564 0.65 part

[0069] Silicone oil DC5598 0.65 parts

[0070] Eco-friendly paraffin 15.5 servings

[0071] 0.45 part of bismorpholinyl diethyl ether

[0072] 0.45 part of tetramethylhexanediamine

[0073] Deltamethrin 0.75 parts

[0074] Permethrin 0.75 parts

[0075] Camphor 0.75 servings

[0076] Tian Lan Kui 0.75 servings

[0077] Plastic additive DCP 596 2 parts

[0078] Plastic additive DCP 381 2 parts

[0079] Urea formaldehyde 0.5 part

[0080] 1 part ammonium polyphosphate

[0081] 1 part potassium polyphosphate

[0082] 1 copy of photochromic powder MC19#

[0083] Polymerized MDI 39 parts

[0084] HFC-245fa 6 servings

...

Embodiment 3

[0090] A one-component polyurethane foam gap filler, which is composed of the following components in parts by weight:

[0091] Polyether polyol Softcel U-1000 5 parts

[0092] Polyether polyol Arcol 1150 8 parts

[0093] Polytetrahydrofuran glycol PolyTHF 250 9 parts

[0094] Silicone oil DC5357 1.2 parts

[0095] Silicone oil DC5564 0.8 parts

[0096] Silicone oil DC5598 0.8 parts

[0097] Eco-friendly paraffin 17 parts

[0098] 1,4 dimethylpiperazine 0.6 part

[0099] 0.6 part of tetramethylhexanediamine

[0100] Deltamethrin 1 part

[0101] 1 part permethrin

[0102] 1 part marigold

[0103] 1 serving of celery

[0104] Plastic additive DCP 542 3 parts

[0105] Plastic additive DCP 381 3 parts

[0106] Urea formaldehyde 1.5 parts

[0107] Ammonium polyphosphate 1.5 parts

[0108] Potassium polyphosphate 1.5 parts

[0109] Photochromic powder MC22# 1.5 parts

[0110] 40 parts of polymerized MDI

[0111] HFC-1234 7 copies

[0112] HFC-227ea 11 servings

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com