Oily sludge treatment method

A sludge treatment and sludge technology, which is applied in biological sludge treatment, dewatering/drying/concentrating sludge treatment, and oxidation treatment of sludge, etc., can solve problems such as inability to effectively treat oily sludge, and achieve oil removal efficiency. High, short processing cycle, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

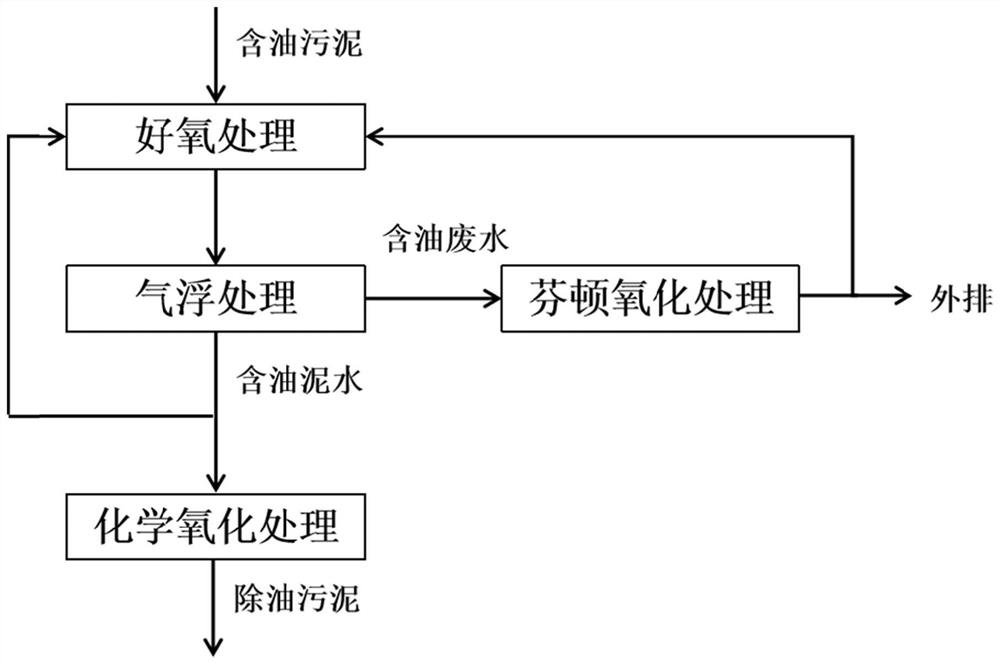

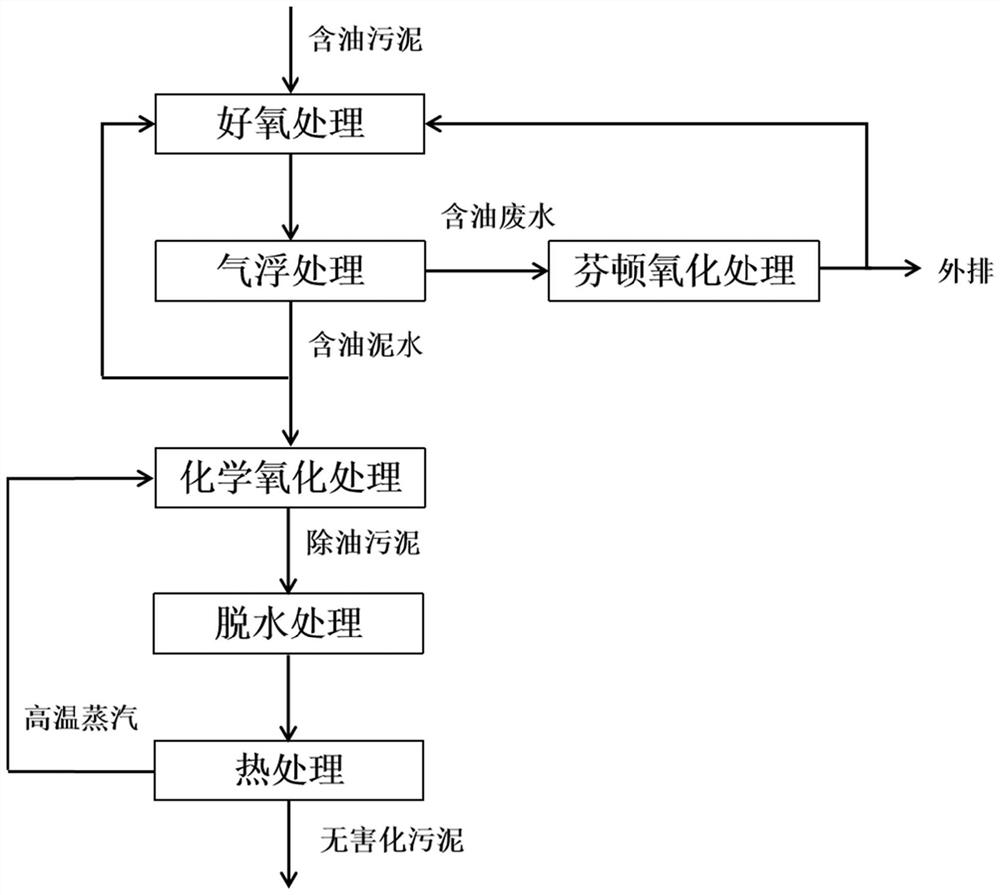

[0048] Taking the cleaning sludge and floor sludge of a branch of Sinopec as the treatment object, it is preliminarily determined that the oil content of the mixed sludge of the cleaning sludge and the floor sludge is between 25% and 35%. After that, the salinity of the mixture is between 10% and 25%. with attached figure 2 The process flow shown is for oily sludge treatment.

[0049] Take 2 tons of oily sludge and clean water / recycled water in a volume ratio of 1:3 after removing large debris and homogenizing, and uniformly mix them in an aerobic tank for aerobic treatment, and add 10% of the treated oily sludge to the ocean. Oil-tolerant bacteria, marine oil-tolerant bacteria are mainly composed of Acinetobacter venetianus, Bacillus pumilus, Marinobacter hydrocarbonoclasticus, Alcanivorax sp., marine oil-tolerant bacteria were purchased from marine microorganisms in China Culture Collection Management Center (MCCC), the MLSS in the aerobic tank is controlled at 0.5-1.0g / L...

Embodiment 2

[0056] Taking the cleaning sludge and floor sludge of a branch of Sinopec as the treatment object, it is preliminarily determined that the oil content of the mixed sludge of the cleaning sludge and the floor sludge is between 25% and 35%. After that, the salinity of the mixture is between 10% and 25%. The treatment process is attached figure 2 , using conventional aerobic activated sludge instead of marine oil-tolerant bacterial agent for technical comparison.

[0057] Take 2 tons of oily sludge and clean water / recycled water in a volume ratio of 1:3 after removing large debris and homogenizing, and uniformly mix them in an aerobic tank for aerobic treatment, according to 10%-20% of the treated oily sludge volume Add oxygen activated sludge, the aerobic activated sludge is the sludge in the aerobic tank of the rural domestic sewage treatment plant. The environmental factors such as MLSS, pH, water temperature, DO in the aerobic tank are the same as those in Example 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com