High-pressure water cutting and discharging centrifugal machine

A centrifuge and high-pressure water technology, applied in the direction of centrifuges, etc., can solve the problems of scraper unloading, reduce centrifugal efficiency, shorten the life of the bag, and achieve the effect of meeting the sealing requirements, improving the centrifugal efficiency, and extending the life of the bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

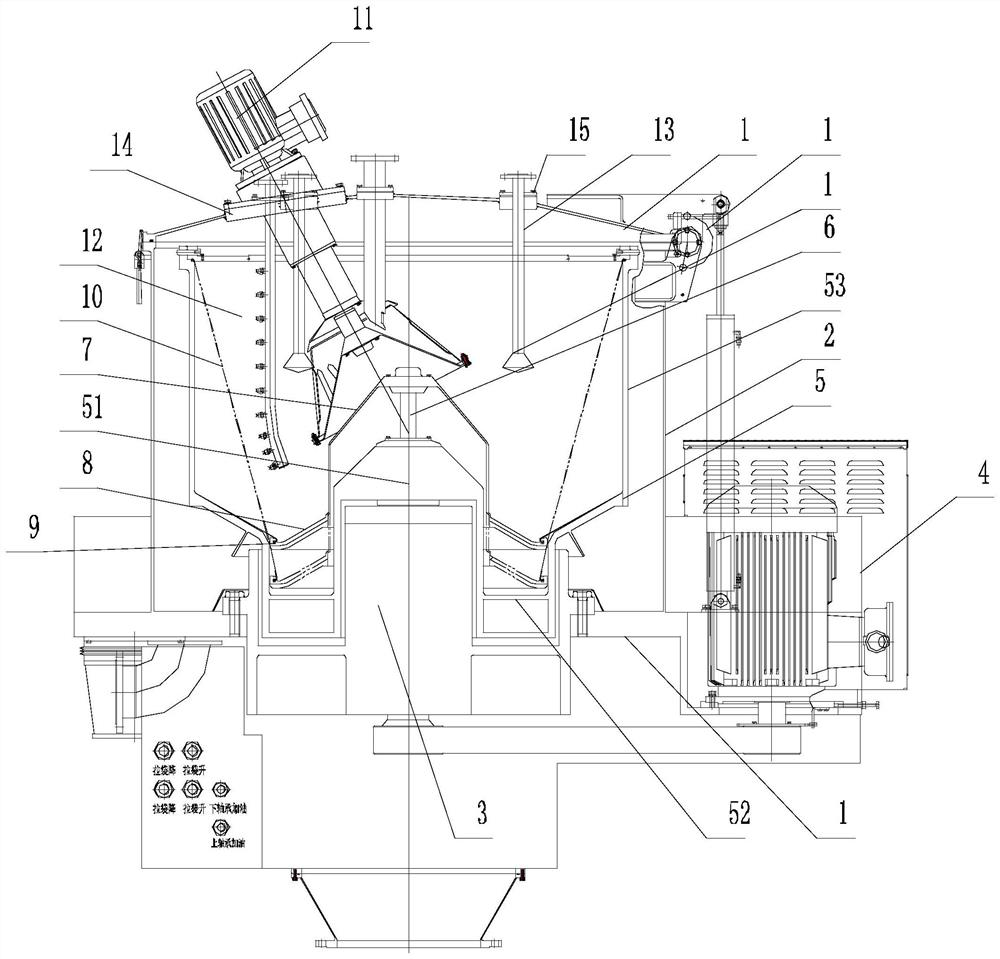

[0021] like figure 1 As shown, a high-pressure water cutting unloading centrifuge includes a base 1, on which a casing assembly 2, a main shaft assembly 3 and a main power device 4 for driving the main shaft assembly 3 are arranged, and a rotating drum 5 is connected to the main shaft. , the drum 5 includes a drum bottom 51 covered on the main shaft, the drum bottom 51 is connected with the drum wall 53 through a number of rib plates 52, the main shaft is vertically movable through a pull bag 10 drive rod 6, the machine base 1 is provided with a pulling bag 10 power device that drives the pulling belt driving rod to move up and down. The upper end of the pulling belt driving rod passes through the drum bottom 51 and is provided with a cover-shaped bag pulling frame 7. The bottom of the pulling bag frame 7 is evenly distributed with At least thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com