Stabilizer, yoghurt and preparation method of yoghurt

A stabilizer and yogurt technology, applied in milk preparations, dairy products, food science, etc., can solve the problem of low fat content and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

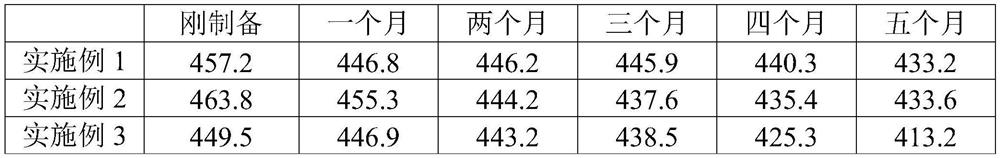

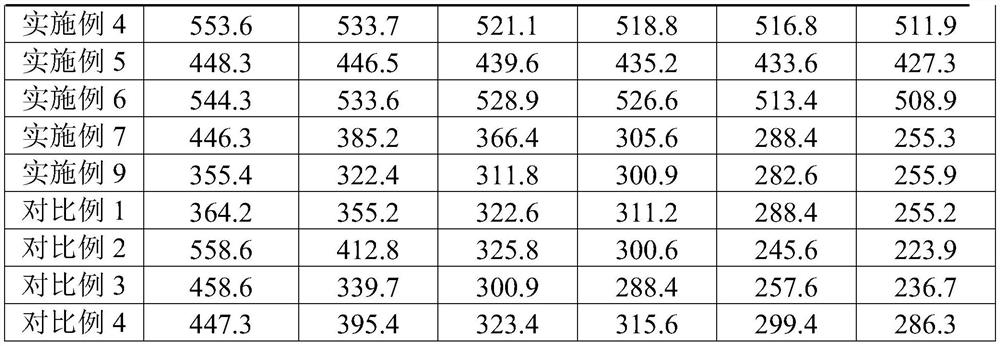

Examples

preparation example Construction

[0043] The embodiment of the present invention also provides the above-mentioned preparation method of yogurt, the preparation method comprises the following steps:

[0044] Get the milk and the stabilizer to prepare a fermentation base;

[0045] The lactic acid bacteria are inserted into the fermentation base material and fermented.

[0046] It can be understood that the lactic acid bacteria in the embodiment of the present invention are fermented under suitable conditions, and the suitable conditions include: the fermentation temperature is 42°C to 45°C, the inoculum amount is 100cfu / 1000kg-200cfu / 1000kg, and the fermented product type is drinking yogurt. .

[0047] In a specific example, the mixture of the milk and the stabilizer is homogenized to prepare the fermentation base material, and the homogenization treatment adopts a secondary homogenization, and the conditions of the secondary homogenization include: a primary pressure of 100 bar ~120bar, secondary pressure 65...

Embodiment 1

[0054] The first step, after the skimmed milk is adjusted from the milk warehouse, the milk is directly pumped into the hot plate (the temperature of the hot plate) with pressure (pressure value 10bar ~ 15bar), so that the milk is heated up to 55 ℃ ~ 65 ℃ in a circular manner, after the heating is completed, the milk is directly pumped. into the ingredient tank.

[0055] The second step is to add raw materials to the above-mentioned batching tank, and mix them evenly at a rotating speed of 2500 rpm. During the process of adding raw materials, the milk is not heated in a cycle to reduce the shearing of the product stabilizer, thereby improving the product stability;

[0056] Among them, in parts by mass, the added raw materials include: 7 parts of inulin, 5 parts of polydextrose, 1.2 parts of pectin, 0.01 part of konjac gum, 0.2 part of tara gum, 0.15 part of keratin, and whey protein powder 5 parts, the sweeteners are 0.03 part of stevioside and 0.01 part of sucralose.

[005...

Embodiment 2

[0064] The first step, after the skimmed milk is adjusted from the milk warehouse, the milk is directly pumped into the hot plate (the temperature of the hot plate) with pressure (pressure value 10bar ~ 15bar), so that the milk is heated up to 55 ℃ ~ 65 ℃ in a circular manner, after the heating is completed, the milk is directly pumped. into the ingredient tank.

[0065] The second step is to add raw materials to the above-mentioned batching tank, and mix them evenly at a rotating speed of 2800 rpm. During the process of adding raw materials, the milk is not heated in a cycle to reduce the shearing of the product stabilizer, thereby improving the product stability;

[0066] Among them, in parts by mass, the added raw materials include: 8.5 parts of inulin, 5.5 parts of polydextrose, 1.4 parts of pectin, 0.02 parts of konjac gum, 0.25 parts of tara gum, 0.17 parts of keratin, and whey protein powder 6 parts, the sweeteners are 0.05 part of stevioside and 0.012 part of sucralose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com