Antimonide semiconductor device and preparation method thereof

An antimonide and semiconductor technology, applied in the field of antimonide semiconductor devices and their preparation, can solve the problems of reversed-phase domain defects, poor compatibility between an antimonide epitaxial layer and a silicon substrate, etc., achieve high crystal quality, and alleviate lattice mismatch. Stress, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 3

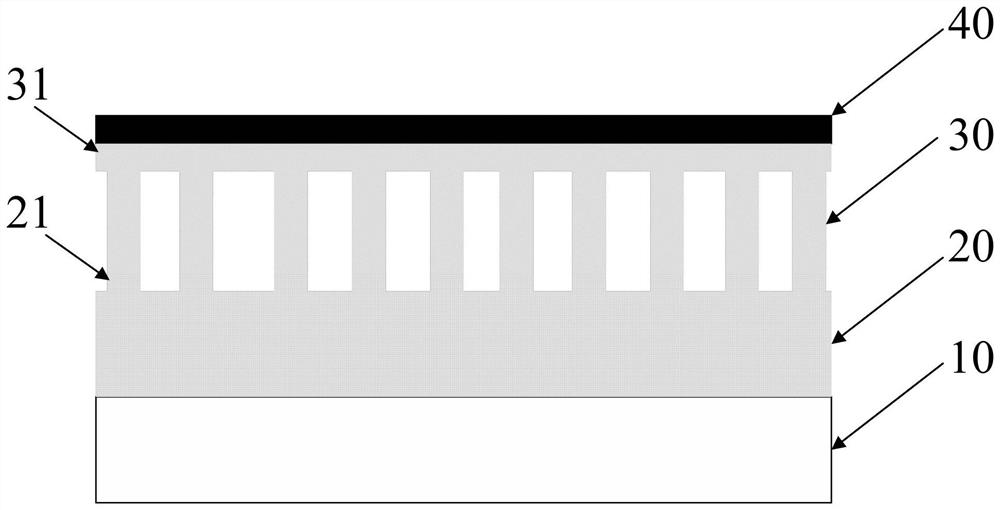

[0050] The present invention also provides a method for preparing an antimonide semiconductor device, and a schematic flow diagram of a specific embodiment thereof is as follows: Figure 5 As shown, it is called specific embodiment three, including:

[0051] S101 : growing a lattice transition buffer layer on the silicon-based substrate 10 .

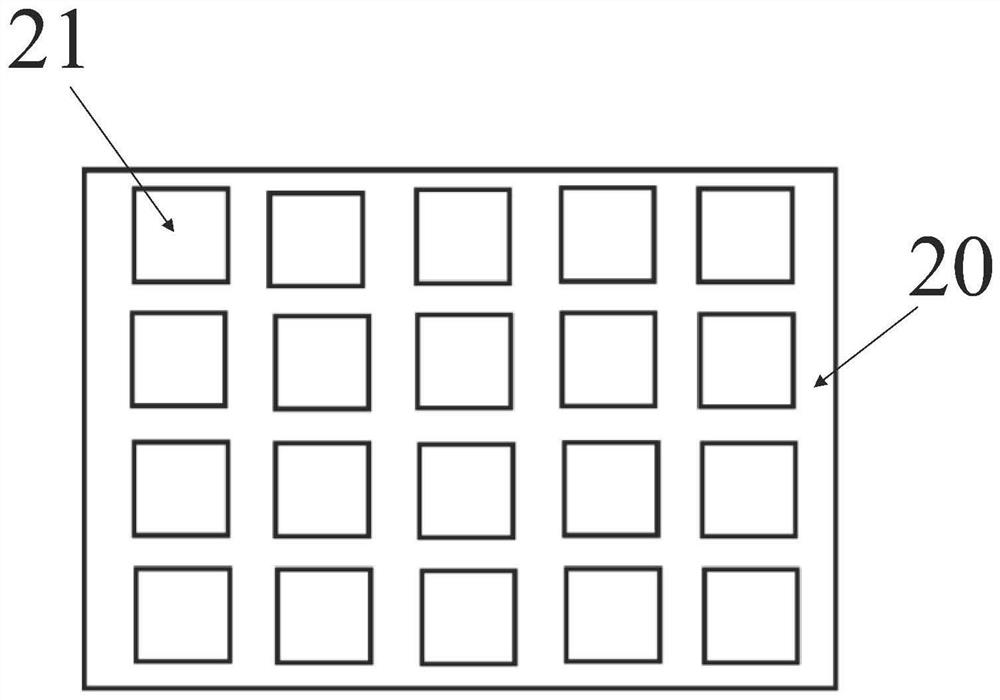

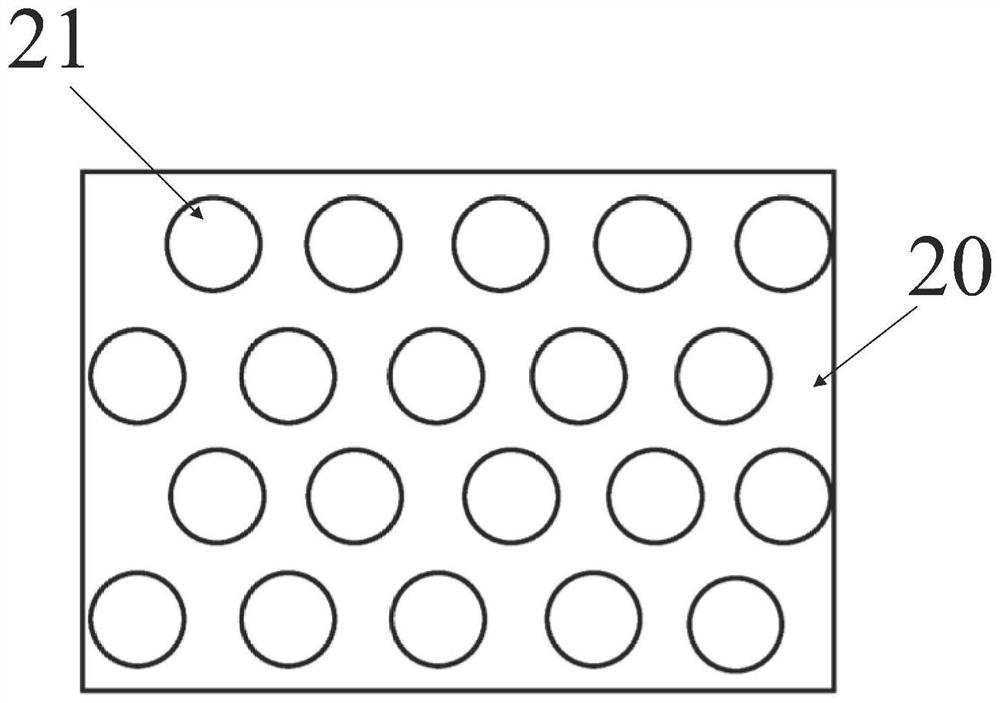

[0052] S102 : Perform patterning processing on the lattice transition buffer layer to obtain a patterned buffer layer 20 including a plurality of raised bases 21 .

[0053] S103 : growing a columnar structure on the patterned buffer layer 20 to obtain a three-dimensional columnar buffer layer 30 ; wherein the tops of the three-dimensional columnar buffer layer 30 are connected to each other to form a two-dimensional crystal plane 31 .

[0054] S104 : growing an antimonide structure layer 40 on the two-dimensional crystal plane 31 to obtain the antimonide semiconductor device.

[0055] The antimonide structure layer 40 may be the conven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com