Device and method for assisting weaving, wrapping and stranding of ceramic fiber fabric

A ceramic fiber and fabric technology, which is applied in the field of auxiliary ceramic fiber fabric weaving and plying device, can solve the problems of insignificant effect, environmental pollution, low efficiency, etc., to improve weaving efficiency and mechanical properties, reduce hairiness, and reduce friction and wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

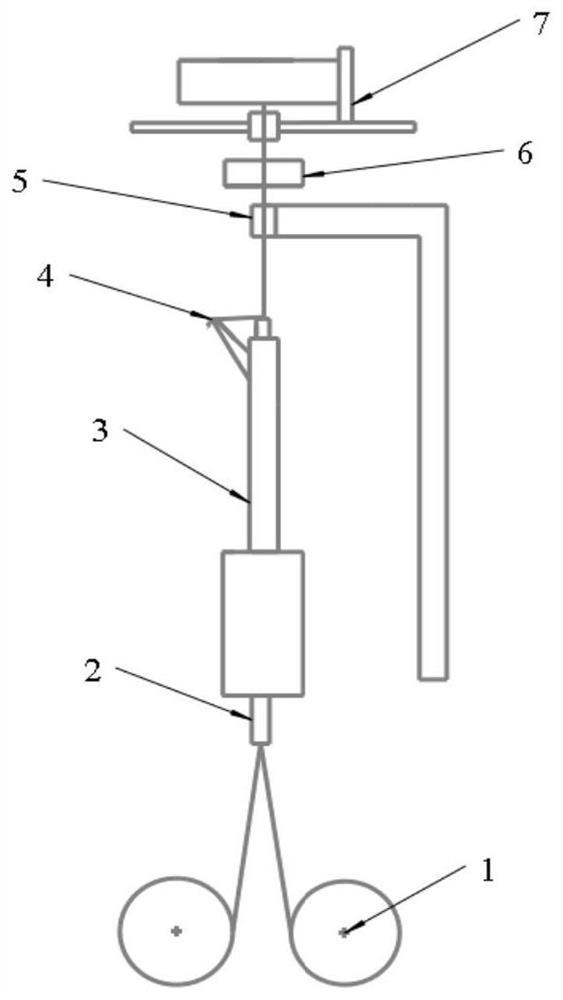

[0030] Aiming at the problems of high brittleness, low elongation, high rigidity, serious fluffing during weaving, and decreased mechanical properties of ceramic fibers, the present embodiment provides an auxiliary ceramic fiber fabric weaving, wrapping and plying device, including:

[0031] bobbin 1, which is used to draw out ceramic fiber bundles;

[0032] The hollow spindle 3 is surrounded by cellulose fibers, and the hollow spindle 3 is provided with a passage for the ceramic fiber bundle to pass through, and the hollow spindle 3 can rotate around its central axis;

[0033] The yarn guide hook 4 can rotate according to the rotation of the hollow spindle 3. After the ceramic fiber bundle passes through the channel, the yarn guide hook 4 guides and wraps the cellulose fibers on the hollow spindle 3 to the On the ceramic fiber bundles, the wrapped ceramic fibers are obtained;

[0034] A winding mechanism 7 is used to wind the wrapped ceramic fibers into a cylinder.

[0035]...

Embodiment 2

[0043] The present embodiment also provides a method for assisting the weaving, wrapping and plying of ceramic fiber fabrics, comprising the following steps:

[0044] Step S1: the ceramic fiber bundle is unwound through the bobbin 1, and the two ceramic fiber bundles after unwinding are merged and passed through the hollow rod 2 inside the hollow spindle 3;

[0045] Step S2: The cellulose fibers on the hollow spindle 3 bypass the yarn guide hook 4, and the yarn guide hook 4 rotates with the hollow spindle 3, and guides and wraps the cellulose fibers to the combined two ceramic strands during the rotation On the fiber bundle, the wrapped ceramic fiber is obtained;

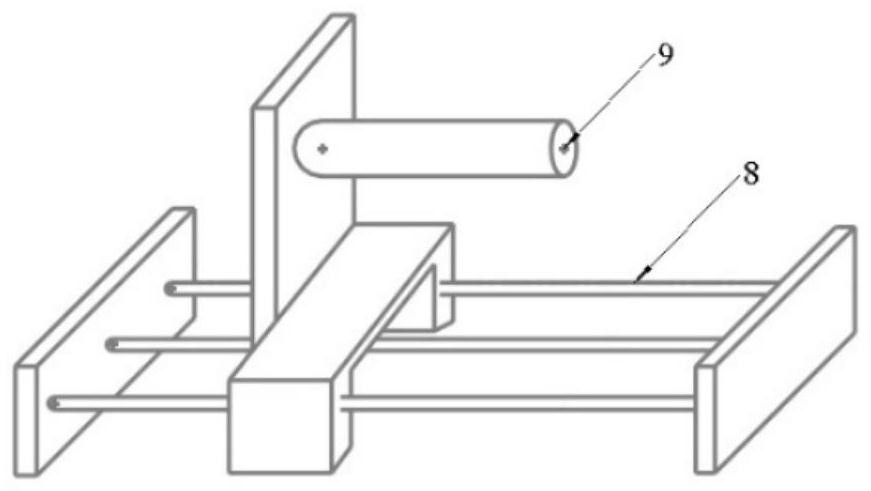

[0046] Step S3: The wrapped ceramic fiber passes through the yarn guide handle 5, and then goes around a pair of yarn takeoff rollers 6. The bobbin 9 moves left and right on the ball screw 8 under the drive of the power device, and the wrapped ceramic fiber is rotated by rotating. The fibers are evenly wound onto t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com