Energy-saving universal oil-water separation device

An oil-water separation device, energy-saving technology, applied in separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc. , heavy oil separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

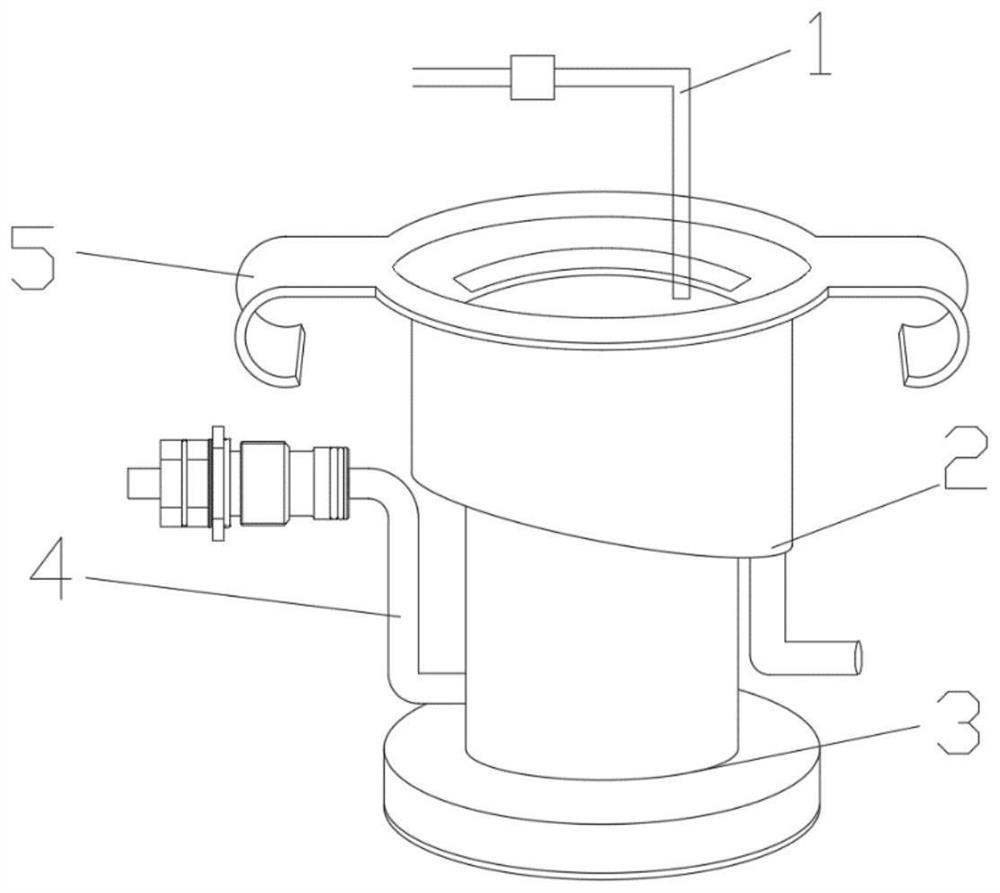

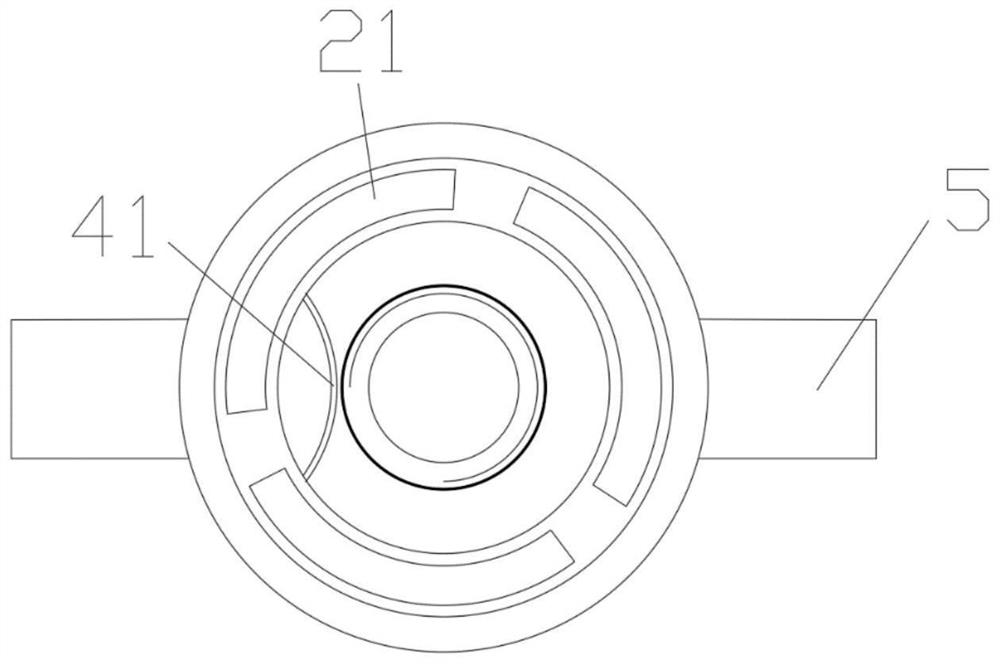

[0030] refer to Figure 1-4 , an energy-saving general oil-water separation device and a separation method thereof, the structure of which is: comprising an oil-water mixture injection unit 1, a light oil / water separation unit 2, a heavy oil / water separation unit 3, a drainage unit 4 and a fixed unit 5;

[0031] The oil-water mixture injection unit 1 includes a pump 11 and an injection pipe 12 for realizing continuous and automatic injection of the oil-water mixture; the light oil / water separation unit 2 includes a filter module based on a super-hydrophobic-super-oleophilic metal mesh 21 and light oil discharge channel 22; the heavy oil / water separation unit 3 includes a superhydrophobic-superoleophilic filter screen 31 for filtering heavy oil / water mixed liquid and a fixed module 32 thereof; the drainage unit 4 includes a The partition plate 41, the autonomous drainage module 42 and the overflow valve 43 that the oil is brought out from the drainage unit; the fixing unit 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com