An oil-water separation device for petrochemical refining

An oil-water separation device and petrochemical technology, applied in the direction of separation methods, liquid separation, liquid separation auxiliary equipment, etc., can solve problems such as differences and separation effects that are difficult to achieve the expected goals, and achieve the effect of precise determination and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

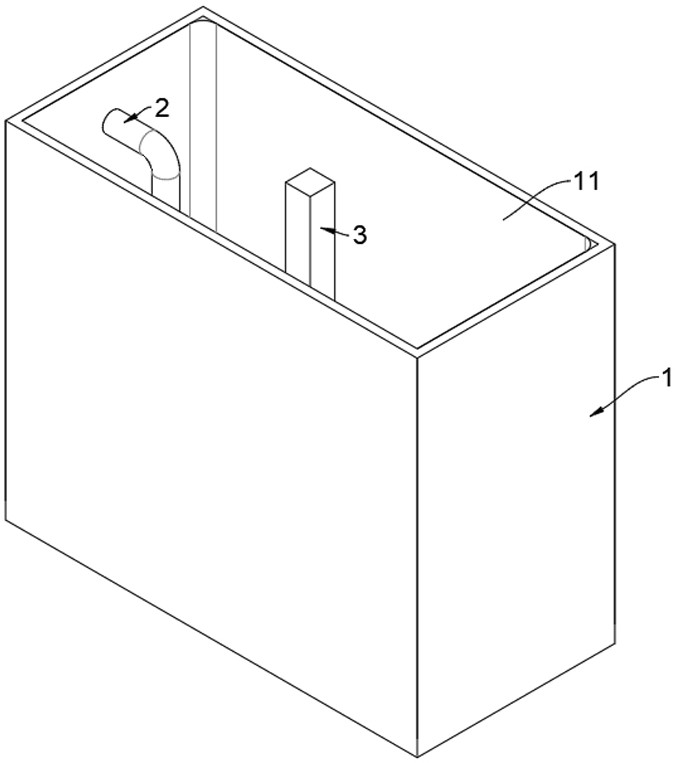

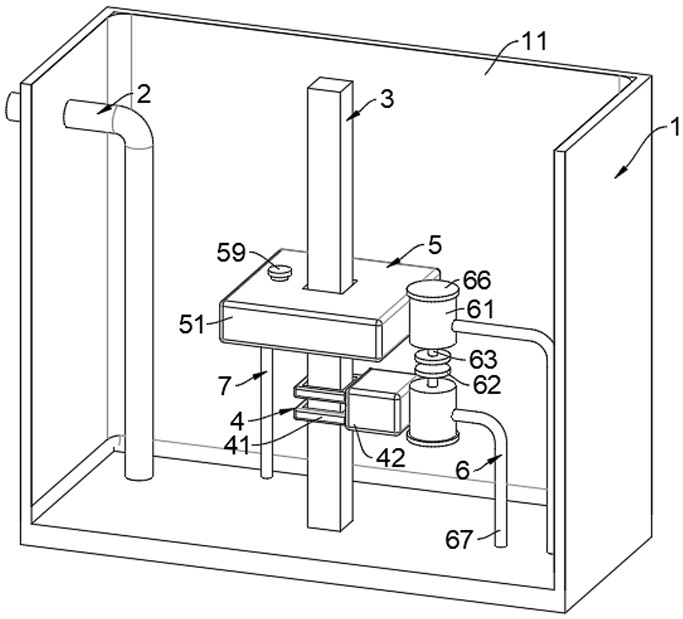

[0028] like Figure 1-7 As shown, an oil-water separation device for petrochemical oil refining includes a separation housing 1. A separation chamber 11 is provided inside the separation housing 1. A feed pipe 2 is fixedly connected to the left side wall of the separation chamber 11. Through the feed pipe 2 to realize the entry of sewage.

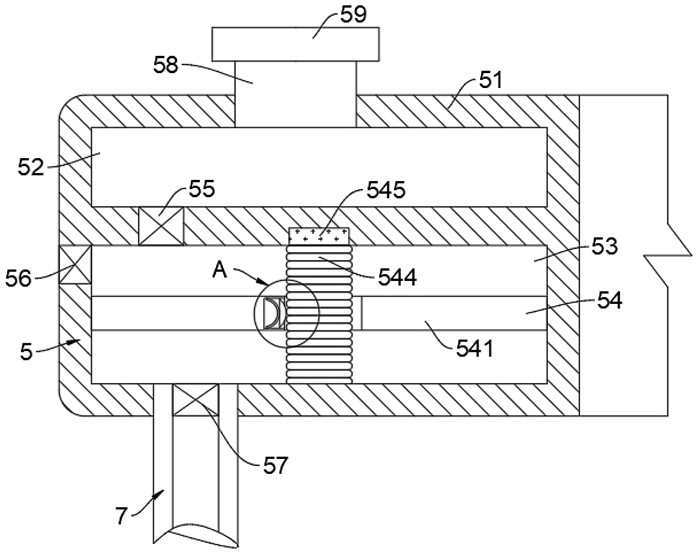

[0029] The center of the bottom wall of the separation chamber 11 is fixedly connected with a support column 3, the support column 3 is vertically arranged, and the support column 3 is a square column, the water surface detection component 4 and the oil level detection component 5 are slidably connected to the support column 3, and the support column 3 is set Forming a square column can realize that the water level detection component 4 and the oil level detection component 5 can only be vertically slidably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com