Auxiliary beam hoisting construction process and construction equipment

A technology of construction equipment and convenient beams, which is applied in the field of construction technology and construction equipment for the hoisting of convenient beams, can solve problems such as shaking of the hoisting device and affect the stability of the hoisting device, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

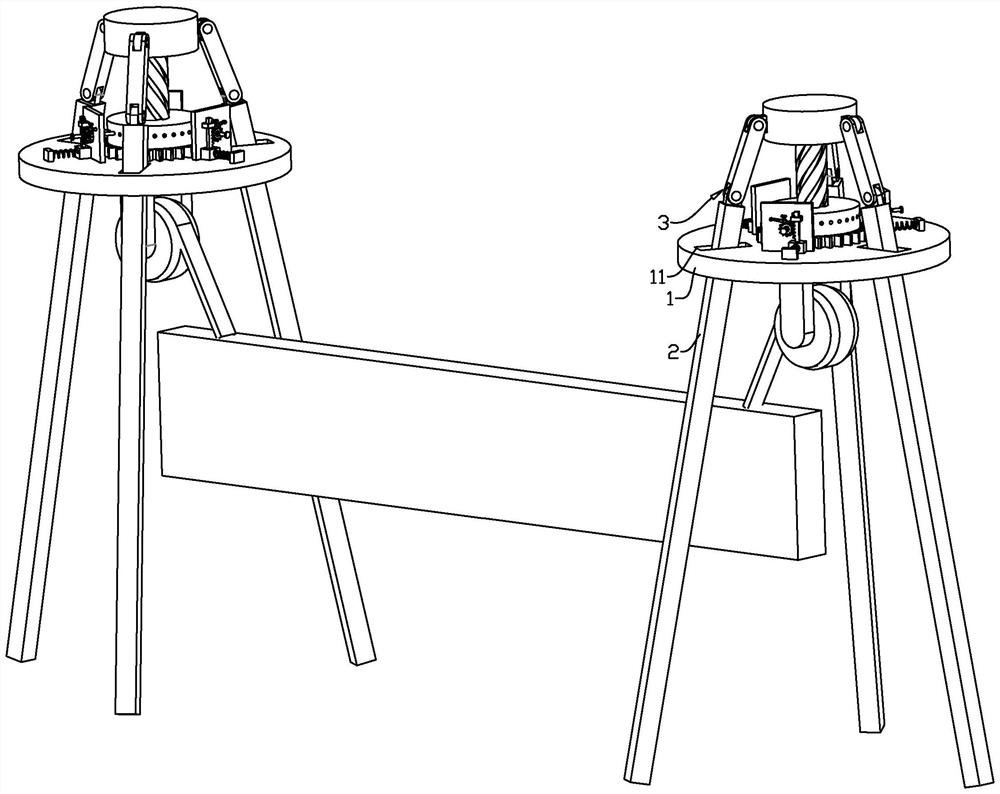

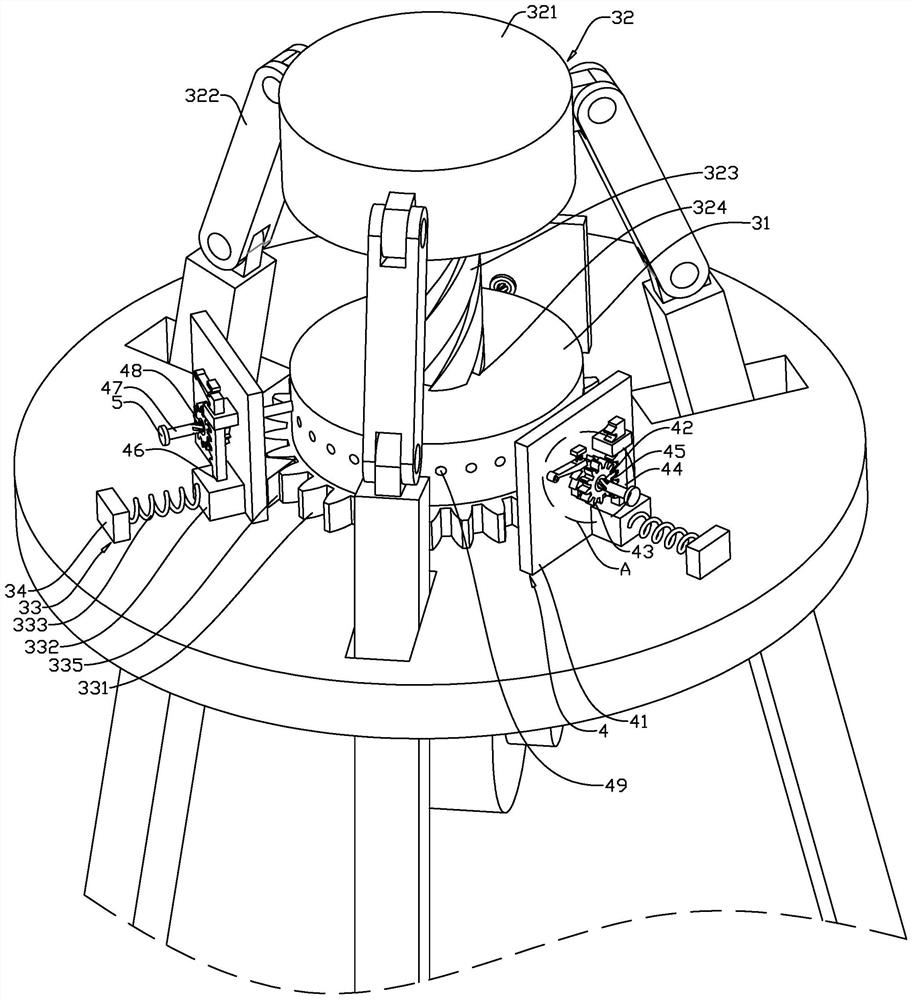

[0041] Attached to the following Figure 1-3 This application will be described in further detail.

[0042] The embodiment of the present application discloses a construction equipment for hoisting a beam. like figure 1 As shown, it includes a top plate 1 and three support rods 2. The top plate 1 is provided with three through holes 11, the through holes 11 extend along the axial direction of the top plate 1, and the three support rods 2 are inserted in one-to-one correspondence with the three through holes 11. In cooperation, a rotating shaft is fixed through the support rod 2, and the two ends of the rotating shaft are respectively connected to the inner walls of the opposite sides of the through hole 11 through bearings.

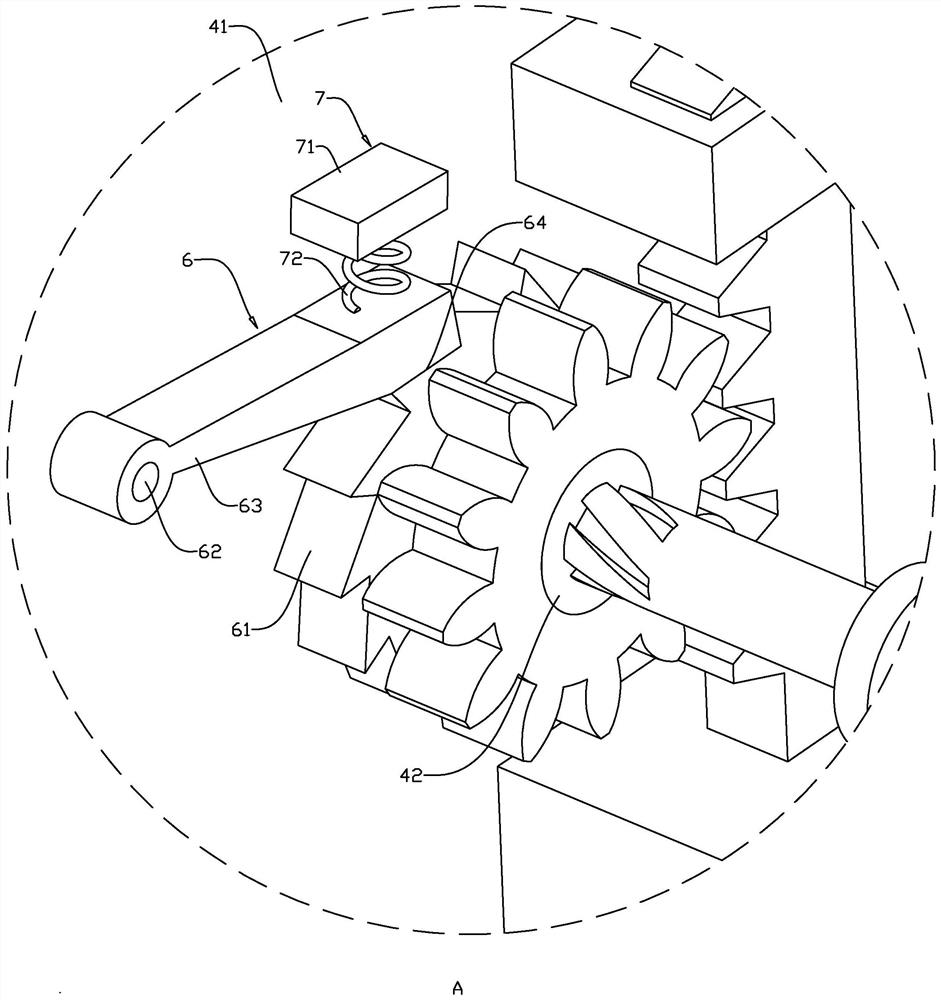

[0043] like figure 1 and figure 2 As shown, the adjusting mechanism 3 includes a first connecting column 31, the first connecting column 31 is cylindrical, and the bottom end of the first connecting column 31 is rotatably connected to the top side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com