Dry-type transformer iron core clamping device with automatic alarm function

A dry-type transformer and iron core clamping technology, which is applied in the field of iron core manufacturing, can solve the problems of damaging the insulation layer of silicon steel sheets, affecting the use of transformers, increasing production costs, etc., and achieves the effect of avoiding air oxidation and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

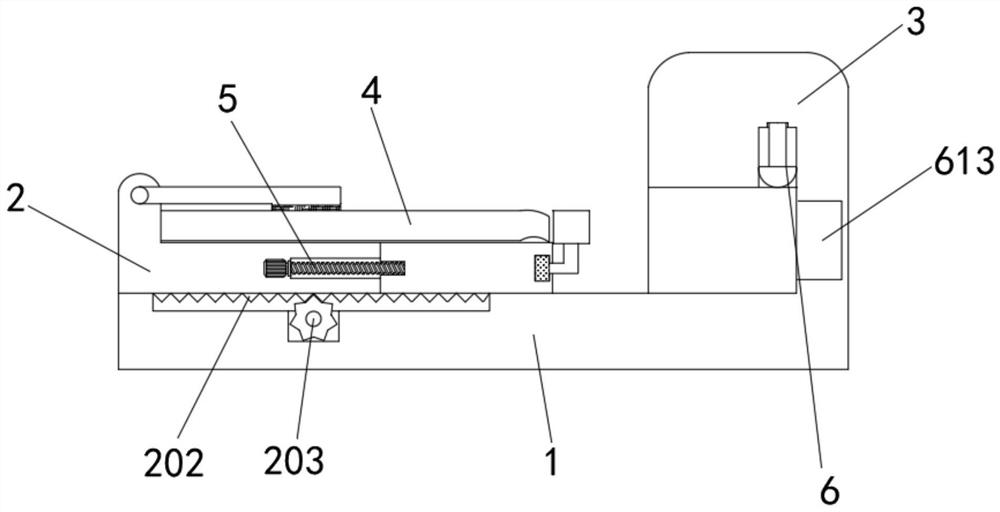

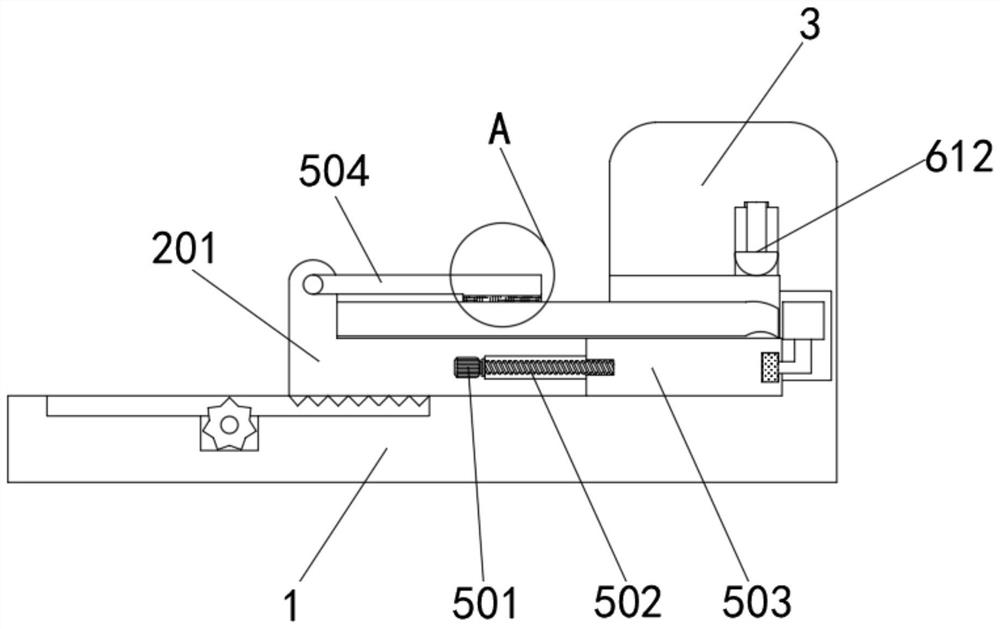

[0032] see figure 1 - Figure 4, a dry-type transformer iron core clamping device with automatic alarm function, comprising a base 1, the upper end of the base 1 is movably installed with a feeding mechanism 2, the upper end of the right side of the base 1 is provided with a mounting block 3, and the feeding mechanism 2 The iron core 4 is clamped and placed inside, the anti-loose mechanism 5 is movably installed on the front and rear sides of the feeding mechanism 2, and the incision maintenance mechanism 6 is movably installed inside the installation block 3. The feeding mechanism 2 includes a movable table 201, and the movable table 201 It is movably installed on the upper end of the base 1. The anti-loose mechanism 5 includes a telescopic block 503. The movable table 201 and the telescopic block 503 are slidably connected. The lower surface of the movable table 201 is fixedly installed with a driven tooth block 202. There is a driving gear 203, and the shape of the outer s...

Embodiment 2

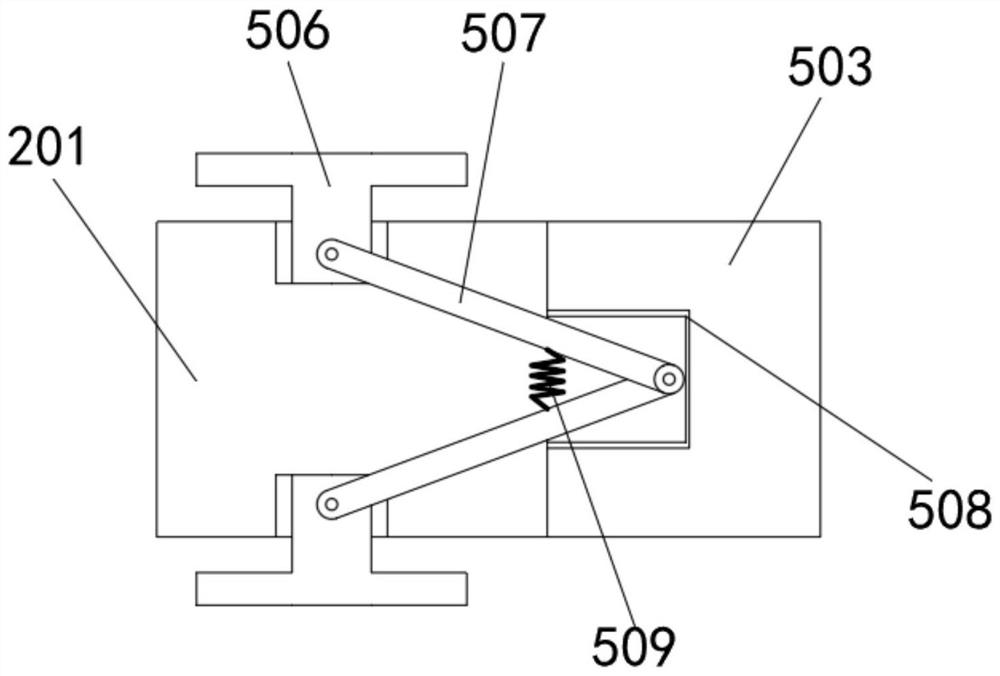

[0041] see Figure 5 - Figure 7 , a dry-type transformer iron core clamping device with automatic alarm function, comprising a base 1, the upper end of the base 1 is movably installed with a feeding mechanism 2, the upper end of the right side of the base 1 is provided with a mounting block 3, and the feeding mechanism 2 The iron core 4 is clamped and placed inside, the anti-loose mechanism 5 is movably installed on the front and rear sides of the feeding mechanism 2, and the incision maintenance mechanism 6 is movably installed inside the installation block 3. The feeding mechanism 2 includes a movable table 201, an anti-loose mechanism 5 includes a telescopic block 503, the movable table 201 and the telescopic block 503 are slidably connected, the incision maintenance mechanism 6 includes a horizontal chute 601, the horizontal chute 601 is opened at the right end of the telescopic block 503, and the interior of the horizontal chute 601 is slidably connected with a drive As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com