Braid alignment processing hemmer

A crimping device and crimping technology, which is applied to sewing equipment, textiles, papermaking, and cloth feeding mechanisms, can solve the problems of cumbersome processing steps, low processing efficiency, and difficulty in simultaneous processing of ribbon hemming and cloth hemming, etc., to achieve Simplify processing steps and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with drawings and embodiments.

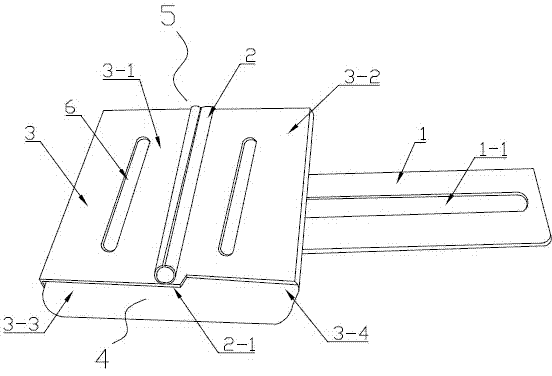

[0009] Such as figure 1 As shown, the present invention includes a fixed plate 1 and a curled plate 3 . Crimping plate 3 comprises base plate, left cover plate 3-1 and right cover plate 3-2, and base plate, left cover plate 3-1 and right cover plate 3-2 encircle and form curling groove 3-4; Left cover plate 3 -1 and the right cover plate 3-2 are spliced by welding. The seam plate 2 is welded at the joint of the left cover plate 3-1 and the right cover plate 3-2, and the seam plate 2 is bent to form a seam groove 2-1; the seam groove 2-1 is arranged on the seam groove 3-4 and It is located at the center line of crimping groove 3-4. The fixed plate 1 is welded to the bottom plate, and the fixed plate 1 is provided with a fixed groove 1-1. The left cover plate 3-1 and the right cover plate 3-2 are respectively provided with a visible groove 6, which can be used to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com