A kind of supporting equipment for open TBM anti-collapse equipment

A supporting equipment and anti-collapse technology, which is applied in mining equipment, tunnels, earthwork drilling, etc., can solve problems such as time-consuming, increased labor and time costs, increased production input, etc., and achieve the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

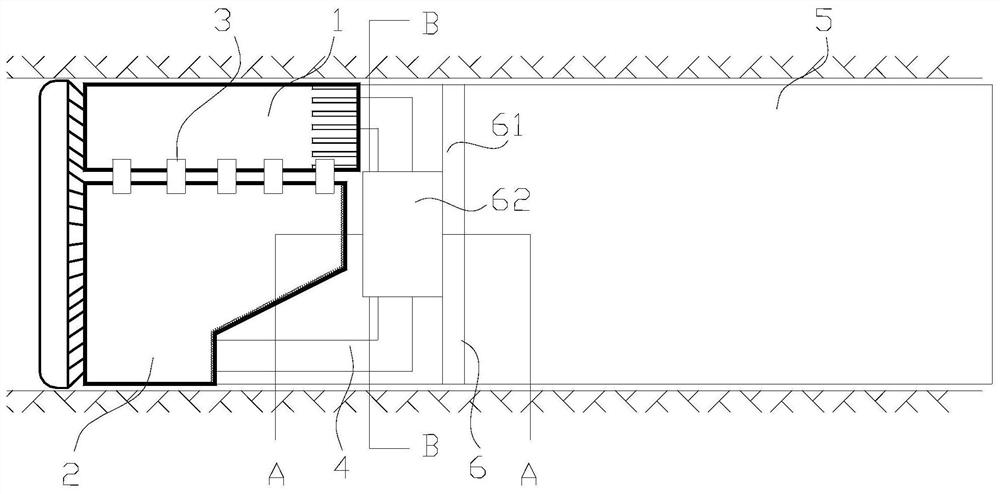

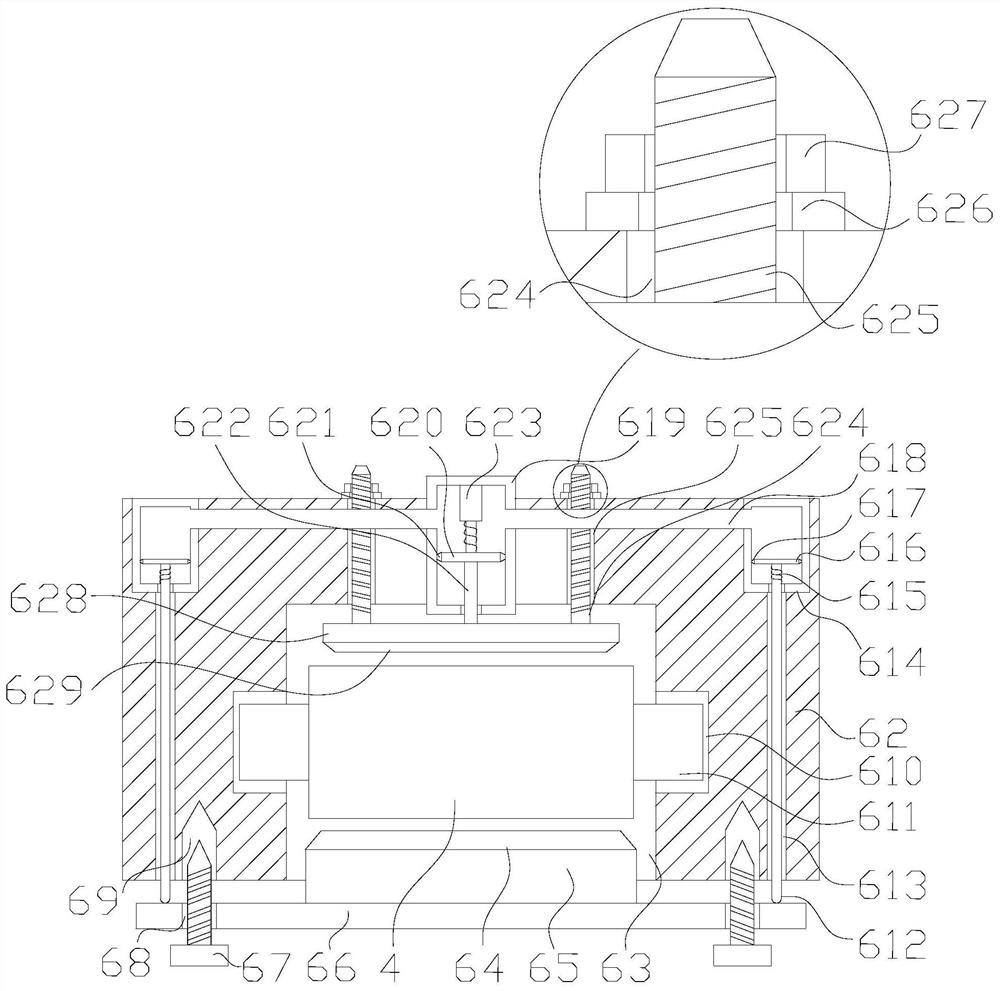

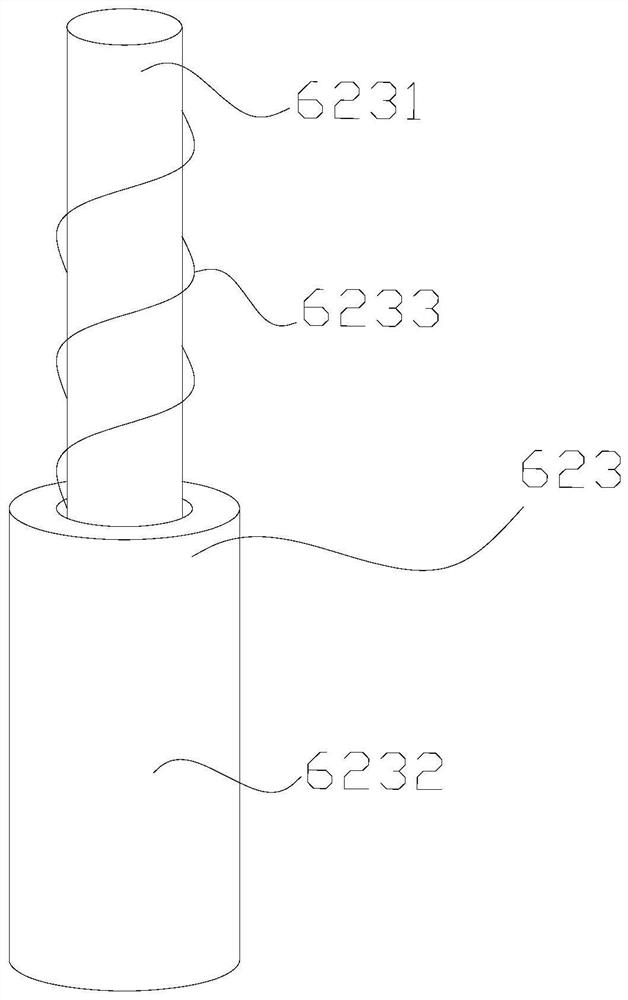

[0034] Attached below Figure 1-5 The present invention is further described with embodiment:

[0035] A support device for an open type TBM anti-collapse equipment, comprising an upper anti-collapse cover 1, a side anti-collapse cover 2, a connecting plate 3, a connecting rod 4, a tunneling machine casing 5 and a supporting mechanism 6, and the lower part of the upper anti-collapse cover 1 Two side anti-collapse covers 2 are arranged symmetrically on the end face, and the connection between the upper anti-collapse cover 1 and the side anti-collapse cover 2 is connected by several connecting plates 3, and the setting of the connecting plates 3 is used to connect the upper anti-collapse cover. For the cover 1 and the side anti-collapse cover 2, in the specific design, the number of connecting plates 3 on one side of the upper anti-collapse cover 1 is set to 5; the upper anti-collapse cover 1 and the side anti-collapse cover 2 are far away from the head One end is connected thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com