Automatic constant-temperature mechanism for differential box body of electric tricycle

A technology for electric tricycles and differential boxes, which is applied to differential transmissions, transmissions, mechanical equipment, etc. It can solve problems such as poor flow effects, accelerated gear wear, and poor cooling effects, so as to improve gear transmission effects and enhance heat dissipation effect, the effect of accelerating the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

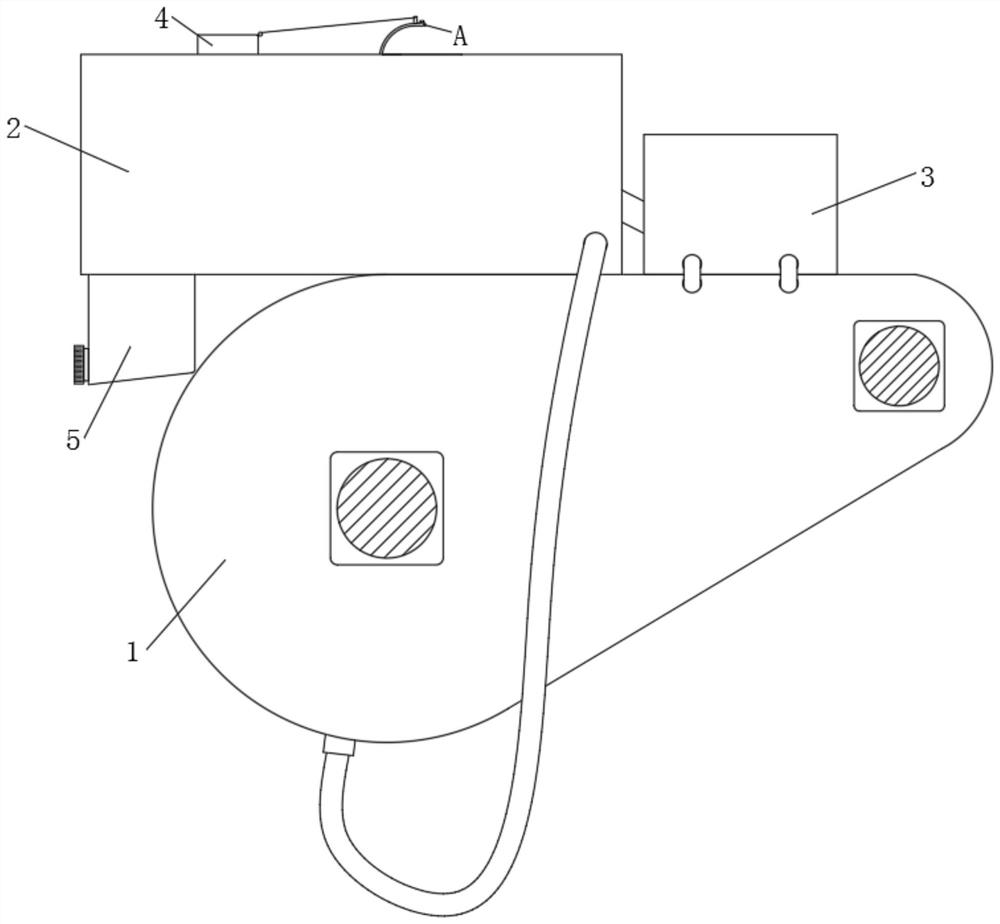

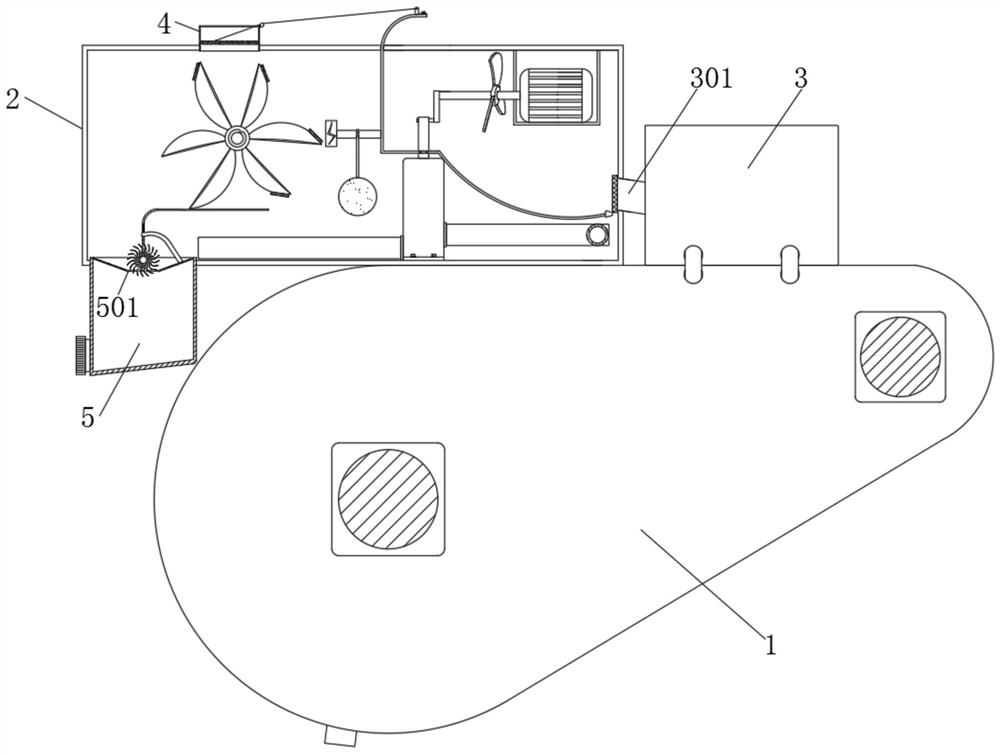

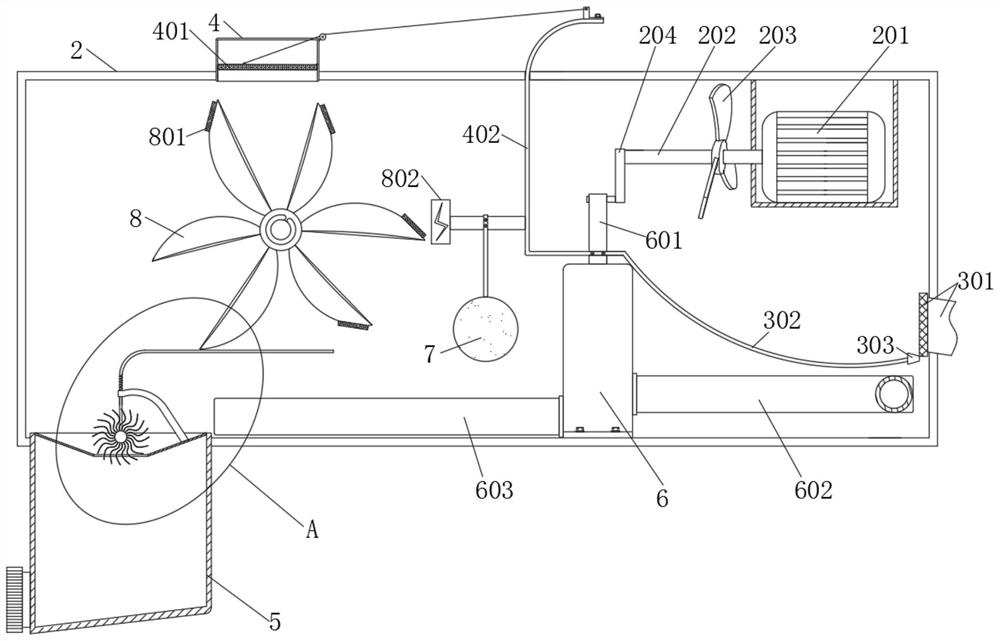

[0038] like Figure 1 to Figure 3As shown in the figure, the automatic constant temperature mechanism of the differential box body of the electric tricycle in this embodiment includes a differential box body 1, a cooling box 2 and a liquid injection box 3. A motor 201 is installed on the top inner wall of the cooling box 2, and the motor 201 is A driving rod 202 is installed on the output shaft, a fan blade 203 is installed on the surface of the driving rod 202, an eccentric wheel 204 is installed at the end of the driving rod 202, and an extrusion tube 6 is installed inside the cooling box 2, and the extrusion pipe 6 is installed inside the cooling box 2. A drive mechanism is installed on the pressure pipe 6 , a heat dissipation mechanism is installed on the top of the cooling box 2 , a synchronization mechanism is installed on the inner wall of the cooling box 2 below the heat dissipation mechanism, and a collection mechanism is installed at the bottom of the cooling box 2 . ...

Embodiment 2

[0041] On the basis of Example 1:

[0042] like image 3 As shown in the figure, the electric tricycle differential case box of this embodiment is an automatic constant temperature mechanism. Further, the driving mechanism includes a piston connecting rod 601, a one-way suction pipe 602, a one-way discharge pipe 603 and a screening component, and the extrusion pipe 6 There is a piston connecting rod 601 installed inside, and the piston connecting rod 601 extends out of the surface of the extrusion tube 6, the extension part of the piston connecting rod 601 is connected with the movable part of the eccentric wheel 204, one side of the extrusion tube 6 is installed with a one-way A one-way drain pipe 603 is installed on the other side of the suction pipe 602 and the extrusion pipe 6 .

[0043] At work: as image 3 As shown, on the basis of the rotation of the eccentric wheel 204, the rotation of the eccentric wheel 204 will also drive the piston connecting rod 601 to move up a...

Embodiment 3

[0045] On the basis of Examples 1 and 2:

[0046] like image 3 and Figure 4 As shown, in this embodiment, the electric tricycle differential case box body is automatically thermostatted. Further, the screening component includes a second side rod 302, a scraper 303 and a filter tube 301. One side surface of the piston rod 601 is installed with a second side rod 302. A scraper 303 is installed at the end of the side rod 302 and the second side rod 302 , a filter tube 301 is commonly connected between the cooling tank 2 and the liquid injection tank 3 , and the scraper 303 is used in conjunction with the filter tube 301 .

[0047] At work: as image 3 and Figure 4 As shown, on the basis of the up and down movement of the piston rod 601, the movement of the piston rod 601 will also drive the second side rod 302 fixedly connected on its surface to move synchronously, and the movement of the second side rod 302 drives the fixed connection at the end. The scraper 303 moves sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com