Breathable polyurethane runway and material mixing device thereof

A mixing device and polyurethane adhesive technology, which is applied in the field of polyurethane processing, can solve problems such as bubbling, poor air permeability, and water discharge, and achieve the effects of increasing overall strength and air permeability, improving unevenness, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

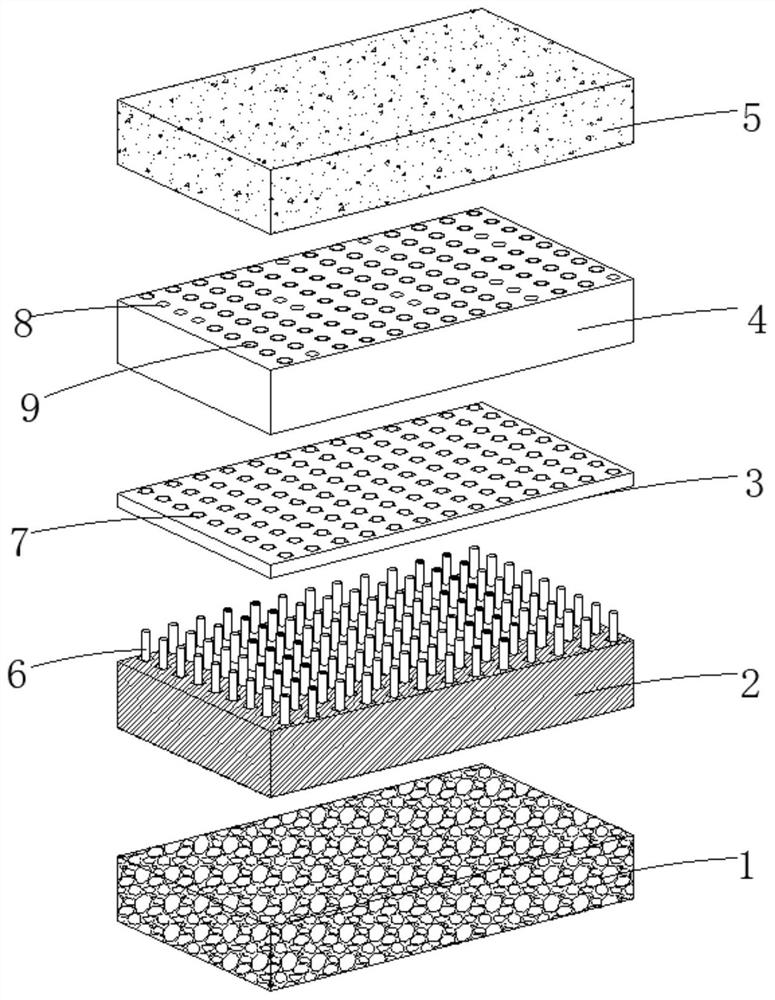

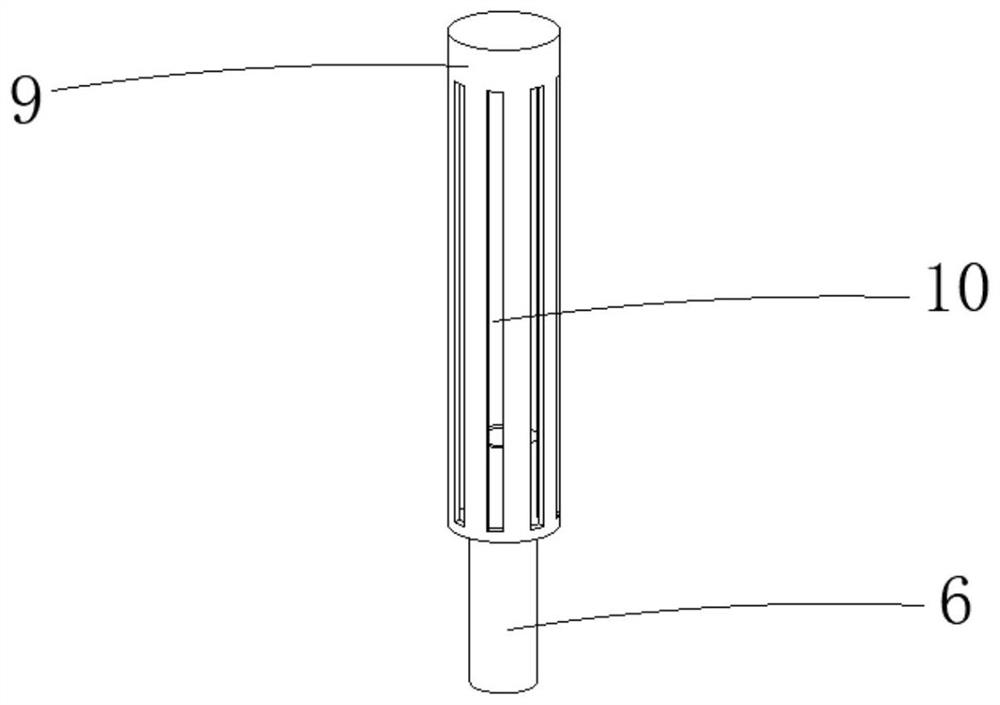

[0028] The present invention provides such as Figure 1-2 A breathable polyurethane runway, comprising a base layer 1, a cover layer 2, a reinforcement layer 3, an elastic particle layer 4 and a spray surface layer 5, the reinforcement layer 3 is equidistantly provided with through holes 7 up and down, and the cover layer 2. The upper surface is provided with a drain slot corresponding to the through hole 7, and a support tube 6 is inserted and installed inside the drain slot, and an installation slot 8 is formed inside the elastic particle layer 4 corresponding to the position of the through hole 7. The inside of the installation slot 8 Reinforcing pipes 9 are provided, and the base layer 1 is made of asphalt to make the bottom of the polyurethane runway more flat, to ensure that the polyurethane runway will not appear bumpy pavement after long-term use, and to increase the service life of the polyurethane runway. The mixed layer of material and black rubber particles can ens...

Embodiment 2

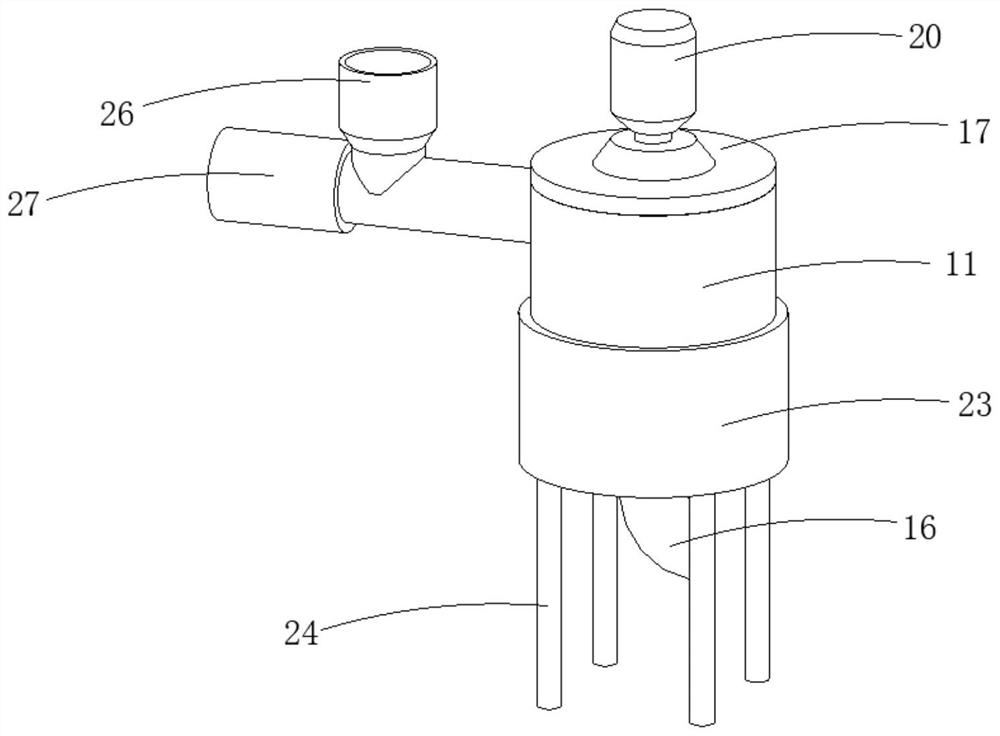

[0033] like image 3 , 4 The air-permeable polyurethane track material mixing device shown includes a mixing bin 11, the bottom of the mixing bin 11 is fitted with a conical leakage pipe 12, and the bottom of the conical leakage pipe 12 is fitted with a leak-proof pipe. Plate 13, an upper cover 17 is correspondingly installed on the upper part of the mixing chamber 11, a feeding pipe 25 is connected to the outside of the mixing chamber 11, and a pushing rod 28 is arranged inside the feeding pipe 25. The mixing chamber 11 and the cone A heating table 23 is installed on the outer surface of the leakage tube 12 , and a support leg 24 is provided at the bottom of the heating table 23 .

[0034] As among them, the mixing bin 11 and the conical leakage pipe 12 are connected and installed by welding, the leakage prevention plate 13 is fitted and installed corresponding to the through hole opened through the bottom of the conical leakage pipe 12, and the upper surface of the leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com