Washable waterproof and color-fixing one-bath finishing process for cotton fabric

A one-bath finishing and waterproof finishing technology, applied in the field of dyeing and finishing technology, can solve the problems of non-washable waterproof effect, poor barrier performance, and long wet processing time, so as to improve color fastness to washing, excellent wearing comfort, The effect of excellent moisture absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The process of washable waterproof finishing and color-fixing same-bath finishing for bright red cotton knitted fabric includes the following steps:

[0043] 1 soaping

[0044] 1.1 Test prescription

[0045] Low temperature soaping powder for cotton DM-1543 0.5g / L

[0046] 1.2 Test process

[0047] The liquor ratio is 1:10, soaping at 80°C for 20min, and draining;

[0048] 2 washes

[0049] Enter water at a liquor ratio of 1:10, wash with cold water for 5 minutes, and drain;

[0050] 3Washable waterproof and solid color finishing in the same bath

[0051] 3.1 Test prescription

[0052] Washable fluorine-free water repellent DM-3696 90g / L,

[0053] Washable formaldehyde-free fixing agent DM-2518 Intermediate 5g / L,

[0054] Bridging agent DM-3918 10g / L.

[0055] 3.2 Test process

[0056] One dipping and one rolling in the shaping machine (rollover rate is about 90%), shaping at 150°C for 2 minutes; no washing and 10 washing in the test

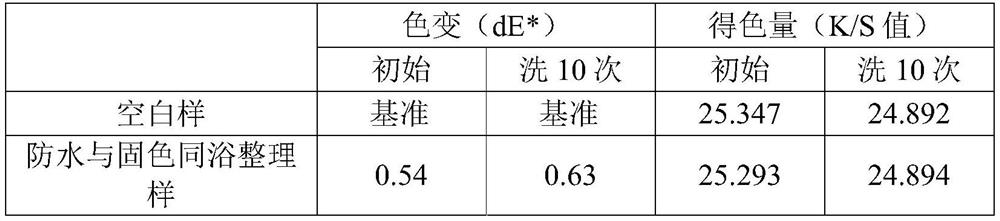

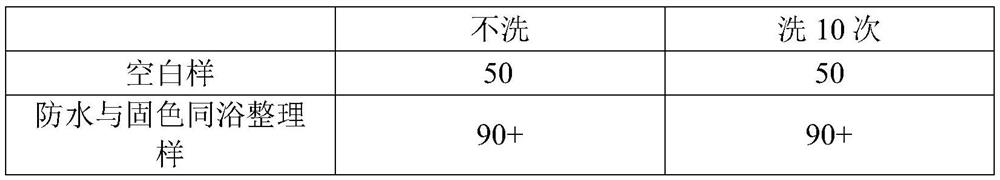

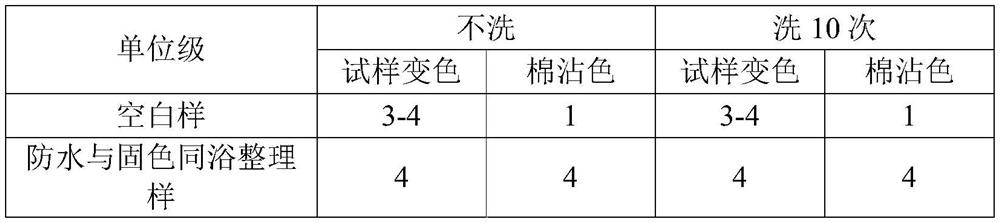

[0057] The various fabric...

Embodiment 2

[0071] The washable waterproof finishing and color-fixing same-bath finishing process of navy blue cotton woven fabric includes the following steps:

[0072] 1 soaping

[0073] 1.1 Test prescription

[0074] Low temperature soaping powder for cotton DM-1543 0.8g / L

[0075] 1.2 Test process

[0076] The liquor ratio is 1:10, soaping at 80°C for 20min, and draining;

[0077] 2 washes

[0078] Enter water at a liquor ratio of 1:10, wash with cold water for 5 minutes, and drain;

[0079] 3Washable waterproof and solid color finishing in the same bath

[0080] 3.1 Test prescription

[0081] Washable fluorine-free water repellent DM-3696 100g / L,

[0082] Washable formaldehyde-free color fixing agent DM-2518 intermediate 10g / L,

[0083] Bridging agent DM-3918 10g / L.

[0084] 3.2 Test process

[0085] One dipping and one rolling in the setting machine (rolling rate is about 80%), setting at 150°C for 2 minutes; no washing, washing for 10 minutes in the test

[0086] The var...

Embodiment 3

[0101] The washable waterproof finishing and color-fixing same-bath finishing process of blue cotton woven fabric includes the following steps:

[0102] 1 soaping

[0103] 1.1 Test prescription

[0104] Low temperature soaping powder for cotton DM-1543 0.5g / L

[0105] 1.2 Test process

[0106] The liquor ratio is 1:8, soaping at 70℃ for 30min, and draining;

[0107] 2 washes

[0108] Enter water at a liquor ratio of 1:8, wash with cold water for 10 minutes, and drain;

[0109] 3Washable waterproof and solid color finishing in the same bath

[0110] 3.1 Test prescription

[0111] Washable fluorine-free water repellent DM-3696 100g / L,

[0112] Washable formaldehyde-free color fixing agent DM-2518 intermediate 12g / L,

[0113] Bridging agent DM-3918 15g / L.

[0114] 3.2 Test process

[0115] One dipping and one rolling in the setting machine (rollover rate is about 80%), setting at 150° C. for 2 minutes; the properties of various fabrics after no washing and 20 times of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com