Crucible device for preparing aluminum nitride prefabricated material

A technology of prefabricated materials and aluminum nitride, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and single crystal growth. It can solve the problems of different physical and chemical properties such as crystallization degree and purity, and inconsistent temperature field distribution. Stable and unified source of raw materials, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

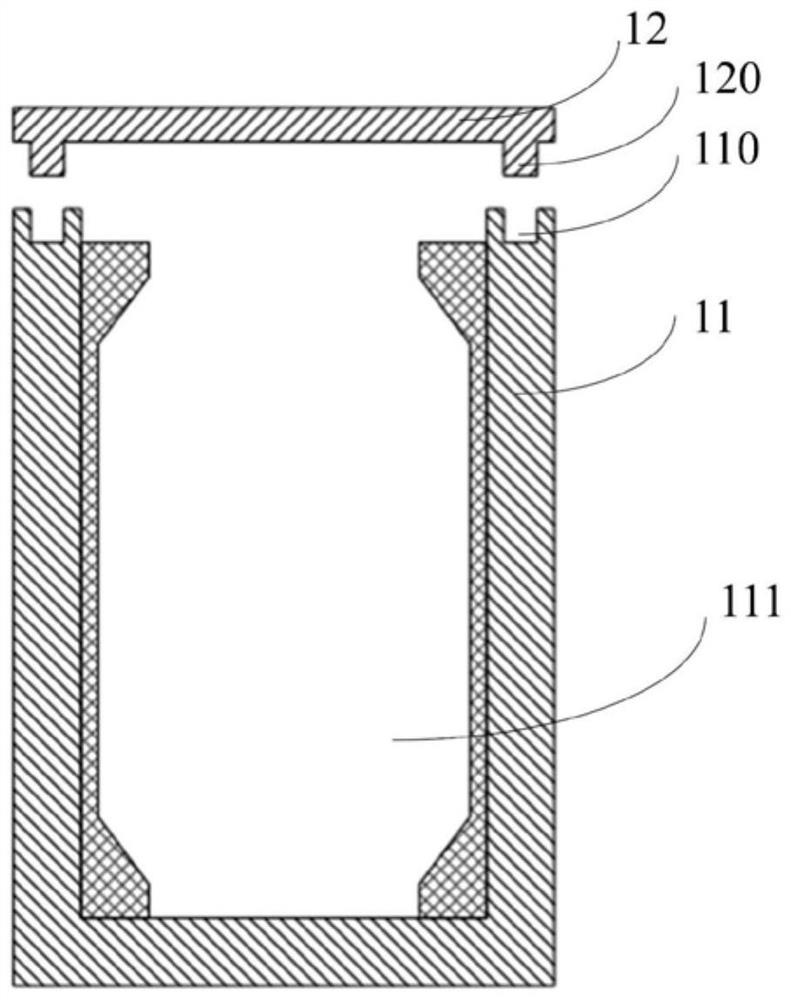

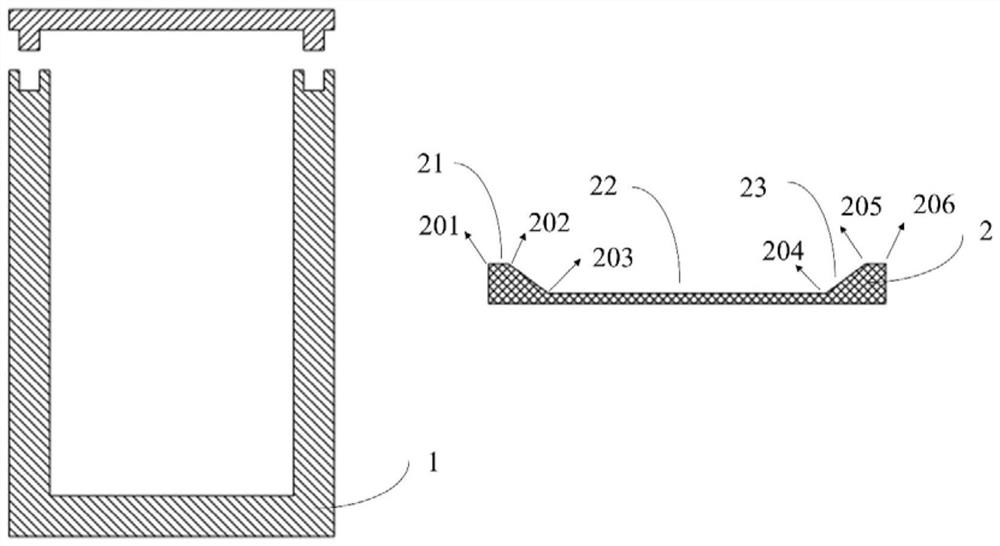

[0025] The crucible device I used for preparing the aluminum nitride preform in Example 1 is as follows: figure 1 and figure 2 shown, where figure 1 A schematic diagram of the overall cross-sectional structure of the crucible device I for preparing aluminum nitride preforms, figure 2 A schematic diagram of the split cross-sectional structure of the crucible device I for preparing aluminum nitride preforms.

[0026] The described crucible device I for preparing aluminum nitride preforms is made of tungsten material, and consists of a crucible 1 and a crucible assembly 2, and the crucible assembly 2 is a detachable structure; wherein, the crucible 1 is a hollow cylinder with a bottom, It consists of a crucible body 11 and a crucible cover 12;

[0027] The crucible body 11 is engaged with the crucible cover 12, the upper mouth wall of the crucible body 11 has a groove structure 110, and the crucible cover 12 has a convex structure 120 matching the groove structure 110, provi...

Embodiment 2

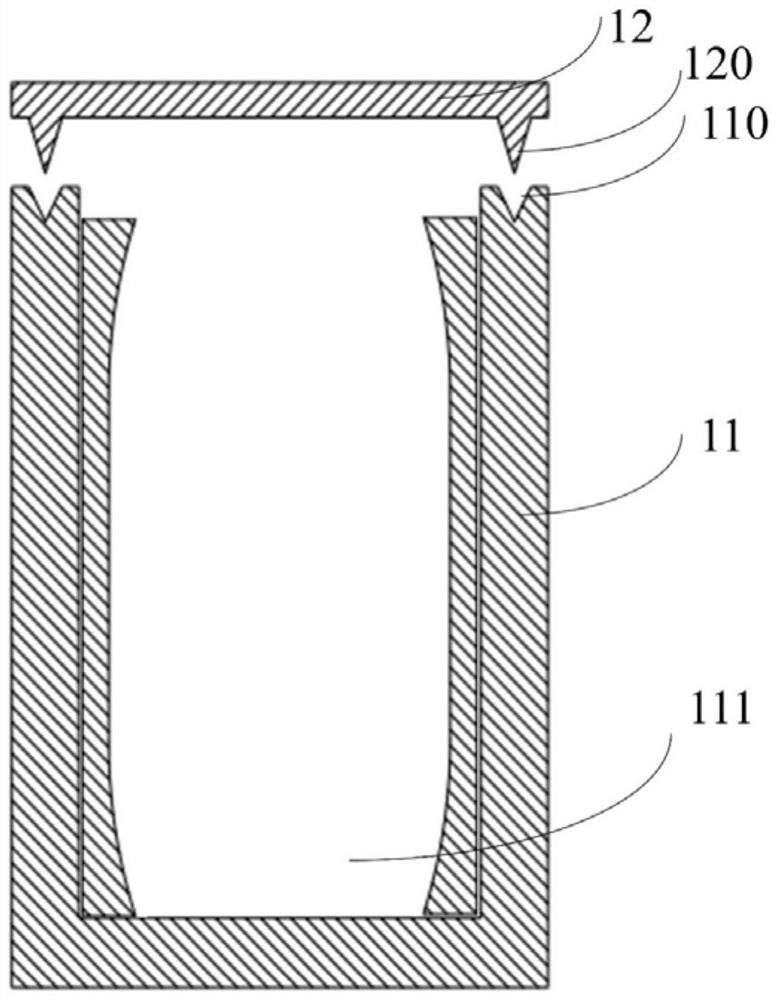

[0030] The crucible device II used for preparing the aluminum nitride preform in Example 2 is as follows: image 3 and Figure 4 shown, where image 3 A schematic diagram of the overall cross-sectional structure of the crucible device II for preparing aluminum nitride preforms, Figure 4 Schematic diagram of split section structure of crucible device II for preparing aluminum nitride preform

[0031] The described crucible device II for preparing aluminum nitride preforms is made of tantalum carbide, and consists of a crucible 1 and a crucible assembly 2. The crucible assembly 2 is a detachable structure; wherein, the crucible 1 is a hollow cylinder with a bottom, consisting of a crucible 1 and a crucible assembly 2. The crucible body 11 and the crucible cover 12 are composed;

[0032] The crucible body 11 is engaged with the crucible cover 12, the upper mouth wall of the crucible body 11 has a groove structure 110, and the crucible cover 12 has a convex structure 120 match...

Embodiment 3

[0035] The described crucible device III for preparing aluminum nitride preform is made of tantalum carbide, and consists of a crucible 1 and a crucible assembly 2, and the crucible assembly 2 is a detachable structure; the structure of the crucible 1 is the same as that of the embodiment 1;

[0036]The crucible assembly 2 is cylindrical, the upper and lower ends are thick, and the middle is thin. , consisting of the thinnest area 22 and the middle area 23, distributed symmetrically up and down; feature point 1 201, feature point 2 202 and feature point 3 203 coincide, feature point 4 204, feature point 5 205 and feature point 6 206 coincide, and the two coincide The point is the thickest area 21, the center is the thinnest area 22, feature point 1 201 (feature point 2 202, feature point 3 203), feature point 4 204 (feature point 5 205, feature point 6 206) and the center The area between the points is the middle area 23, the thickest area 21 of the crucible assembly 2 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com