Stainless steel composite functional coating and preparation method thereof

A composite function, stainless steel technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of functionality and application fields to be developed, and achieve broad market application prospects, coating attachment Focus on excellent, easy to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

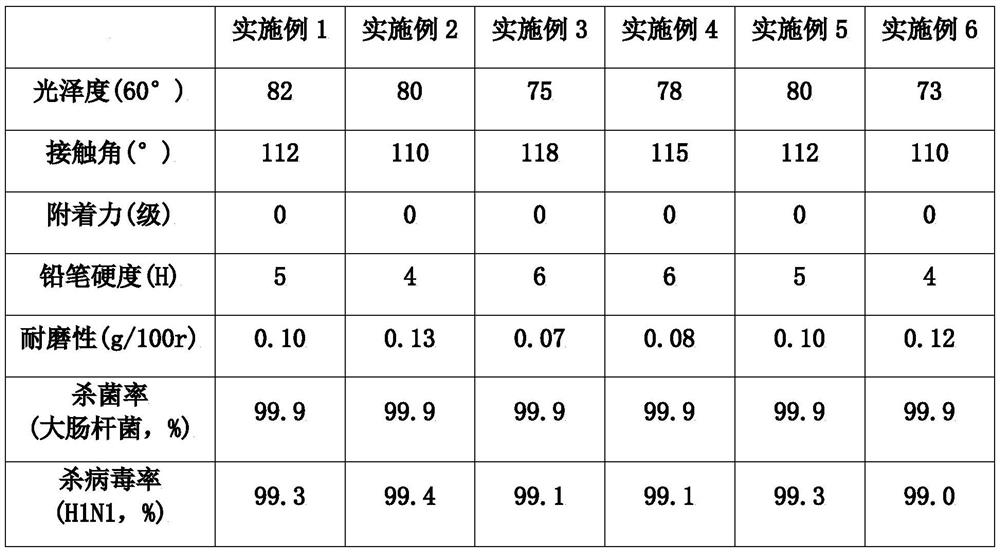

Examples

Embodiment 1

[0022] Firstly, the silicon-zirconium nano-sol was prepared.

[0023] Step 1: Put 19g of ethyl orthosilicate into 60ml of ethanol, put 10g of zirconium acetate into 30ml of water, and stir at a constant speed for 1 hour;

[0024] Step 2: Mix the above two solutions evenly, and ultrasonicate for 10 minutes;

[0025] Step 3: Add 5g of polyvinyl alcohol to the mixed solution, and then drop acetic acid to control the pH value to 5, ultrasonically react at 50°C for 1 hour, and leave to age for 24 hours;

[0026] The fourth step: suction filtration, repeated washing with ethanol three times, and freeze-drying for 48 hours to obtain a silicon-zirconium nano-sol with an average particle size of 20 nm.

[0027] Then weigh the following components: 15g silicon-zirconium nano-sol, 35g modified epoxy acrylic resin Paraloid A11, 6g nano-titanium dioxide with a particle size of 10nm, 2g mica powder, 2g zinc polyphosphate, 45g deionized water, 0.5g poly Ammonium acrylate, 0.2g hydroxyethyl...

Embodiment 2

[0033] Firstly, the silicon-zirconium nano-sol was prepared.

[0034] Step 1: Put 10g of ethyl orthosilicate into 50ml of ethanol, put 5.2g of zirconium acetate into 20ml of water, and stir at a constant speed for 0.5h;

[0035] Step 2: Mix the above two solutions evenly, and ultrasonicate for 10 minutes;

[0036] Step 3: Add 3g of polyvinyl alcohol to the mixed solution, and then drop acetic acid to control the pH value to 4, ultrasonically react at 50°C for 1 hour, and leave to age for 24 hours;

[0037] Step 4: suction filtration, repeated washing with ethanol three times, and freeze-drying for 48 hours to obtain a silicon-zirconium nano-sol with an average particle size of 16 nm.

[0038] Then weigh the following components: 10g silicon-zirconium nano-sol, 30g modified epoxy acrylic resin Paraloid A11, 8g aluminum tripolyphosphate, 5g zinc polyphosphate, 40g deionized water, 0.3g ammonium polyacrylate, 0.3g hydroxyethyl Base cellulose, 0.1g silver-copper composite nanopa...

Embodiment 3

[0044] Firstly, the silicon-zirconium nano-sol was prepared.

[0045] Step 1: Put 20g of ethyl orthosilicate into 80ml of ethanol, put 10.5g of zirconium acetate into 40ml of water, and stir at a constant speed for 1 hour;

[0046] Step 2: Mix the above two solutions evenly, and ultrasonicate for 30 minutes;

[0047] Step 3: Add 5g of polyvinyl alcohol to the mixed solution, and then drop acetic acid to control the pH value to 4, ultrasonically react at 55°C for 1.5h, and leave to age for 36h;

[0048] The fourth step: suction filtration, repeated washing with ethanol three times, and freeze-drying for 48 hours to obtain a silicon-zirconium nano-sol with an average particle size of 19 nm.

[0049] Then weigh the following components: 20g silicon-zirconium nano-sol, 40g modified epoxy acrylic resin Paraloid A11, 4g particle size of 15nm nano titanium dioxide, 1g mica powder, 5g zinc polyphosphate, 50g deionized water, 1g polyacrylic acid Ammonium, 0.2g hydroxypropyl cellulose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com