Near-infrared light-emitting tin-bismuth-doped aluminosilicate glass optical rod and preparation method thereof

An aluminosilicate glass, near-infrared technology, used in glass manufacturing equipment, glass pressing, glass molding and other directions, can solve the problem of low near-infrared luminous efficiency, complex glass sample preparation process, unclear near-infrared luminescence mechanism, etc. problem, to achieve the effect of good luminous efficiency and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

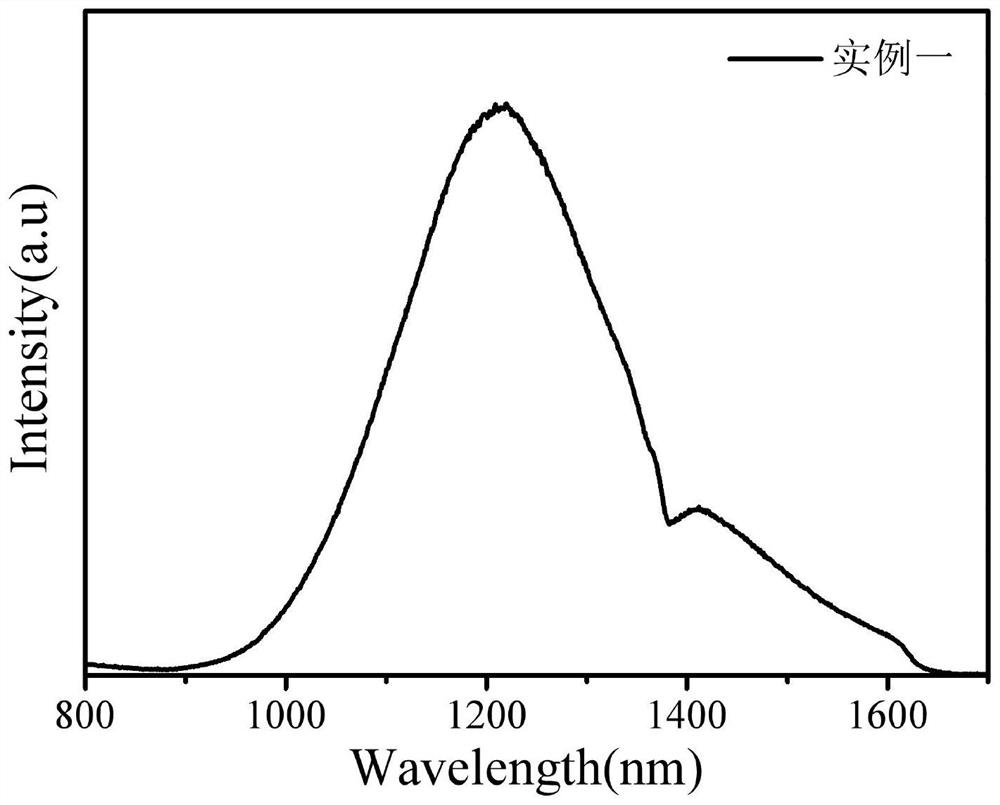

Embodiment 1

[0030] see Figure 1-4 , the present invention provides the following technical solutions: a near-infrared light-emitting tin-bismuth-doped aluminosilicate glass light rod, the molar percentage components of each component are:

[0031]

[0032]

[0033] A preparation method of near-infrared light-emitting tin-bismuth-doped aluminosilicate glass light rod, comprising the following steps:

[0034] S1: Calculate the required amount of each raw material according to the above molar ratio;

[0035] S2: Weigh the raw materials on a high-precision electronic balance;

[0036] S3: Pour each raw material into an agate mortar and grind for 15min in turn, until the mixture is uniform to obtain mixed powder;

[0037] S4: Pour the mixed powder into a high-purity alumina crucible, put the high-purity alumina crucible containing the sample into a high-temperature furnace, and melt at 1600° C. for 90 minutes to obtain a molten glass liquid;

[0038] S5: After the heat preservation, ...

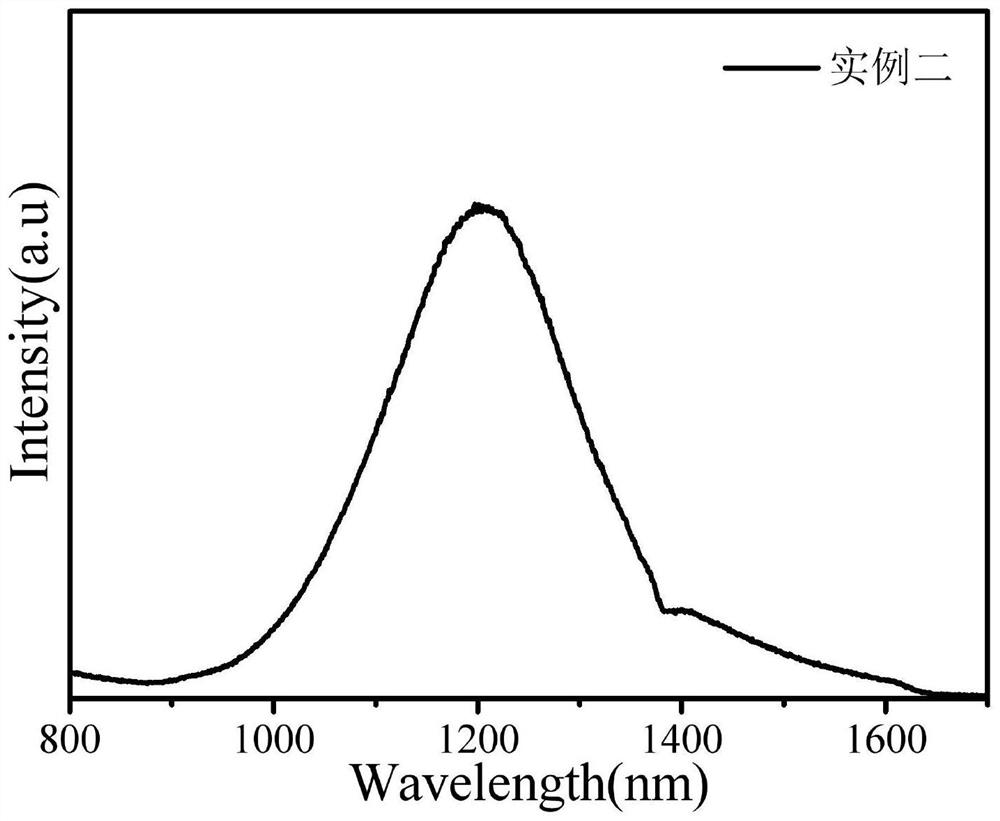

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is:

[0044] see Figure 1-4 , the present invention provides the following technical solutions: a near-infrared light-emitting tin-bismuth-doped aluminosilicate glass light rod, the molar percentage components of each component are:

[0045]

[0046] A preparation method of near-infrared light-emitting tin-bismuth-doped aluminosilicate glass light rod, comprising the following steps:

[0047] S1: Calculate the required amount of each raw material according to the above molar ratio;

[0048] S2: Weigh the raw materials on a high-precision electronic balance;

[0049] S3: Pour each raw material into an agate mortar and grind for 15min in turn, until the mixture is uniform to obtain mixed powder;

[0050] S4: Pour the mixed powder into a high-purity alumina crucible, put the high-purity alumina crucible containing the sample into a high-temperature furnace, and melt at 1600° C. for 90 minutes to obtain a molten...

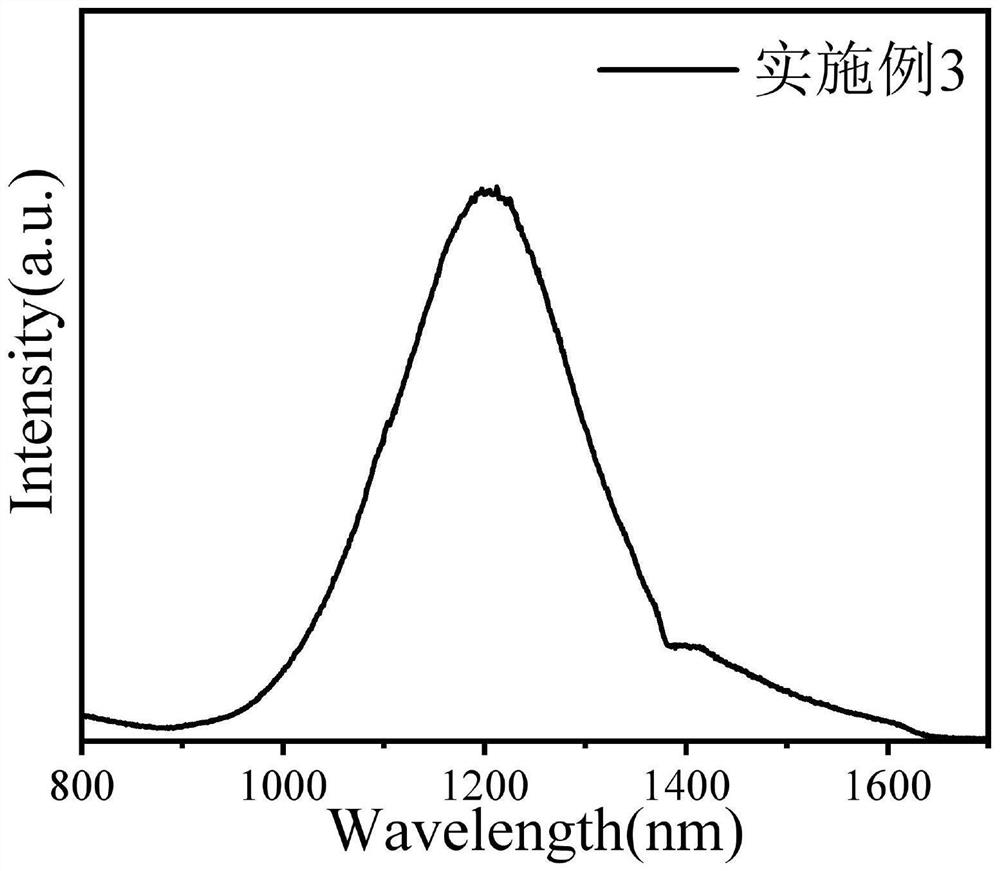

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is:

[0057] see Figure 1-4 , the present invention provides the following technical solutions: a near-infrared light-emitting tin-bismuth-doped aluminosilicate glass light rod, the molar percentage components of each component are:

[0058]

[0059]A preparation method of near-infrared light-emitting tin-bismuth-doped aluminosilicate glass light rod, comprising the following steps:

[0060] S1: Calculate the required amount of each raw material according to the above molar ratio;

[0061] S2: Weigh the raw materials on a high-precision electronic balance;

[0062] S3: Pour each raw material into an agate mortar and grind for 15min in turn, until the mixture is uniform to obtain mixed powder;

[0063] S4: Pour the mixed powder into a high-purity alumina crucible, put the high-purity alumina crucible containing the sample into a high-temperature furnace, and melt at 1600° C. for 90 minutes to obtain a molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fwhm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com