Moisture-absorbing self-drying shirt fabric

A self-drying and shirting technology, which is applied in the field of textile fabrics, can solve the problems of reduced moisture absorption performance, reduced perspiration performance, and affecting comfort, and achieves the effects of improving moisture absorption, light weight, and ensuring comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] see Figure 1-3 , including the following components in parts by weight: 30%-45% cotton, 20%-35% modified polyester fiber, 20%-30% moisture wicking fiber, 15%-30% viscose fiber;

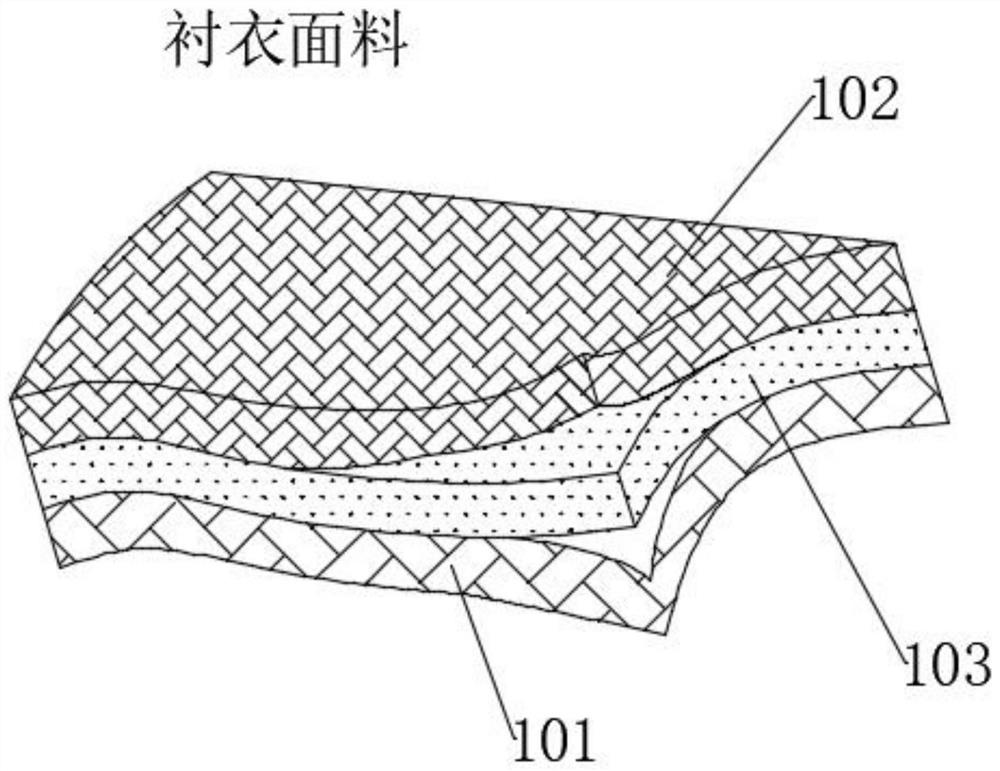

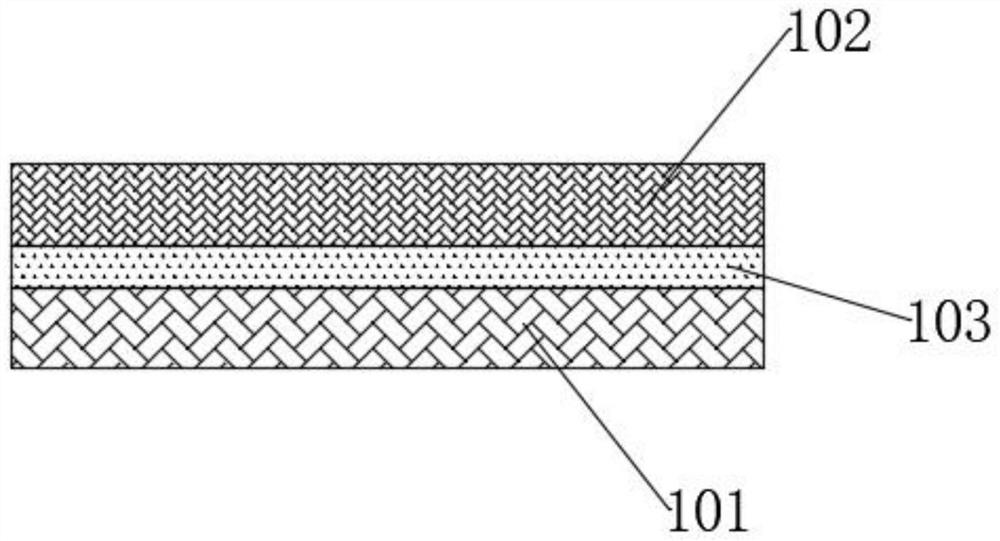

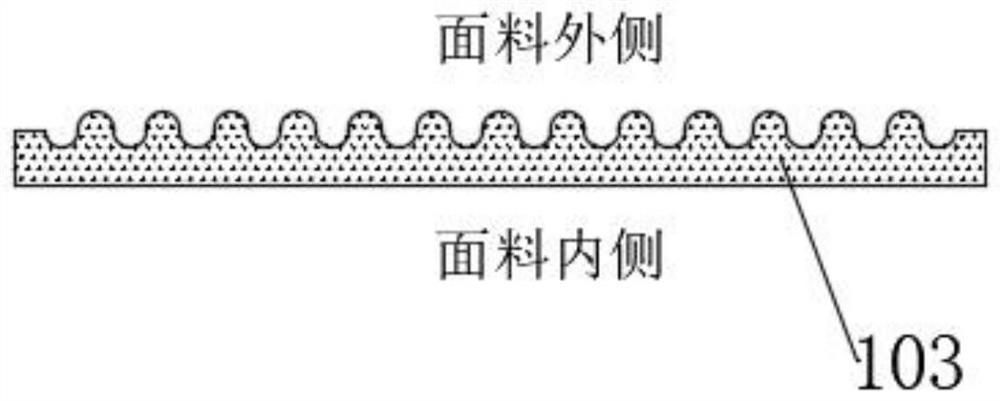

[0040] see Figure 2-3 , the shirt fabric includes a hygroscopic layer 101, a drying layer 102 and an aerogel interlayer 103, and the aerogel interlayer 103 is located between the hygroscopic layer 101 and the drying layer 102, and the three are connected in one by bonding;

[0041] The weight ratios of cotton, modified polyester fibers, moisture-wicking fibers, and viscose fibers in the moisture-absorbing layer 101 and the drying layer 102 are 5:1:2:2 and 1:4:3:2, respectively. Since the moisture-absorbing layer 101 Close to the human skin, in order to ensure comfort and improve hygroscopicity, the cotton composition in the hygroscopic layer 101 should be high, and since the drying layer 102 is used as a decorative surface, in order to ensure no wrinkles and accelerate the evaporation of swe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com