Pipeline inner wall self-adaptive robot cleaning device based on centrifugal force principle

A pipeline robot and centrifugal force technology, applied in the field of robots, can solve the problems of long-distance and poor manual cleaning of variable-diameter pipelines, and achieve the effects of easy removal of stubborn dirt, controllable radial contact force cleaning, and avoiding excessive frictional contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

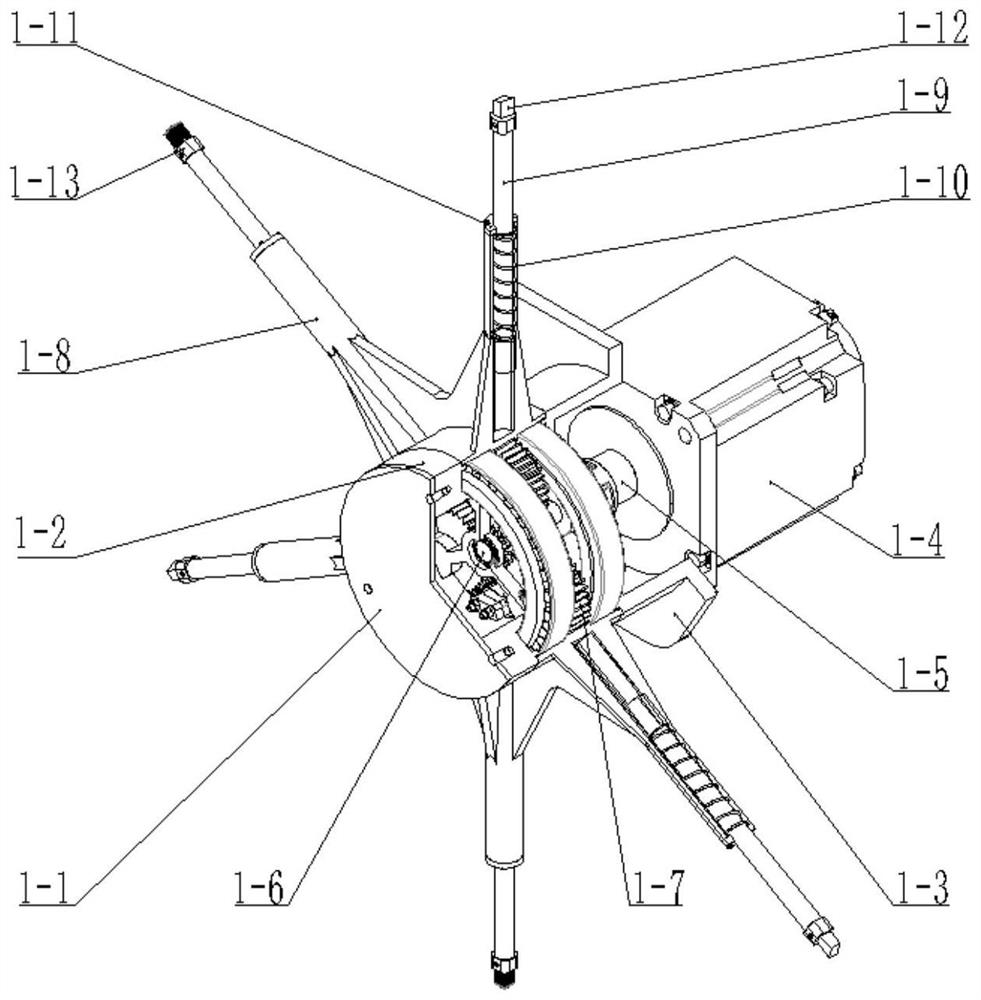

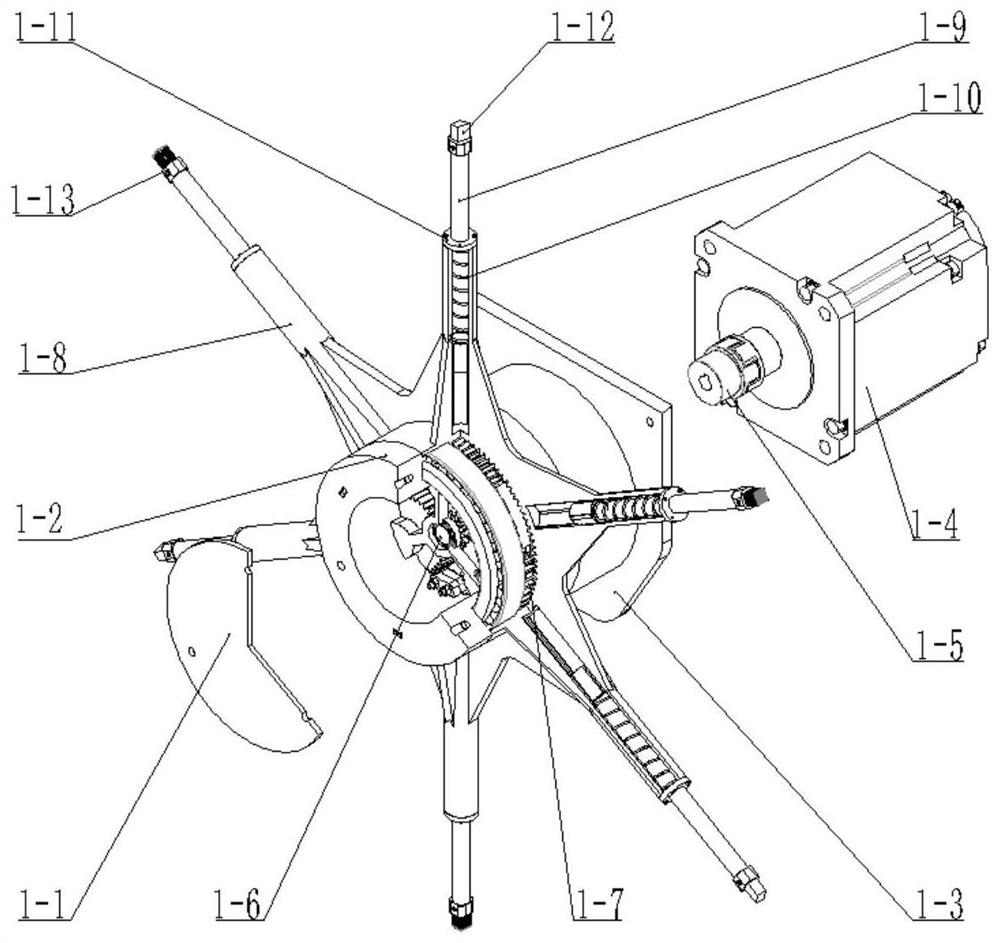

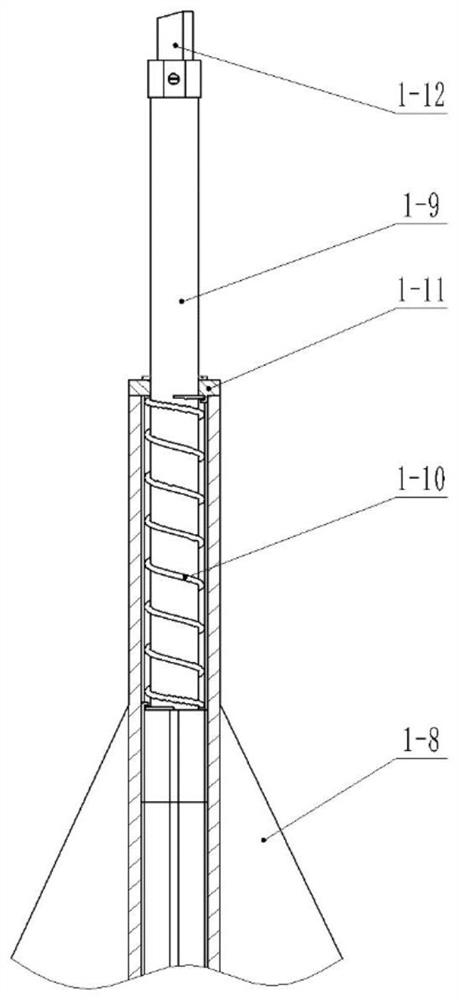

[0032] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0033] like figure 1 , figure 2 and Figure 7 As shown in the figure, the self-adaptive robot cleaning device for the inner wall of the pipeline based on the principle of centrifugal force of the present invention includes a planetary gear transmission bracket composed of a front connecting plate 1-2 and a rear connecting plate 1-3. The cleaning turntable 1-8 of the gear transmission mechanism, the radial bearing and the radial thrust bearing of the corresponding matching size, the plunger 1-9 which can slide radially along the sleeve chute on the cleaning turntable, and the reset shock spring 1-10 , plunger end cover 1-11; two kinds of pipe wall cleaning ends that are replaced according to the degree of dirt, hardness and stubbornness and the wear of the pipe wall cleaning end; sun gear shaft 1-6, planetary gear 1-7 and internal teeth The cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com