Ultra-thick PVDC membrane and preparation method thereof

A manufacturing method and film technology, which are applied in the field of ultra-thick PVDC film and its manufacturing, can solve the problems of increasing the water temperature of thick film socks, and achieve the effects of good mechanical adaptability and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

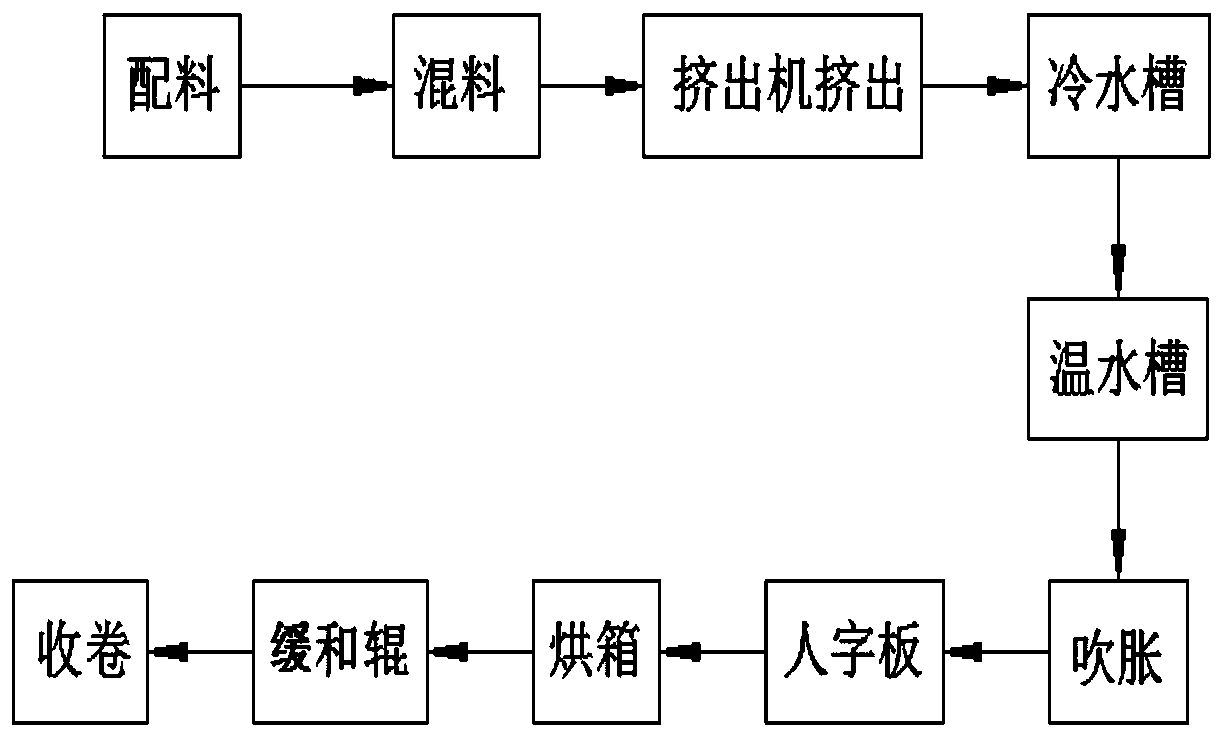

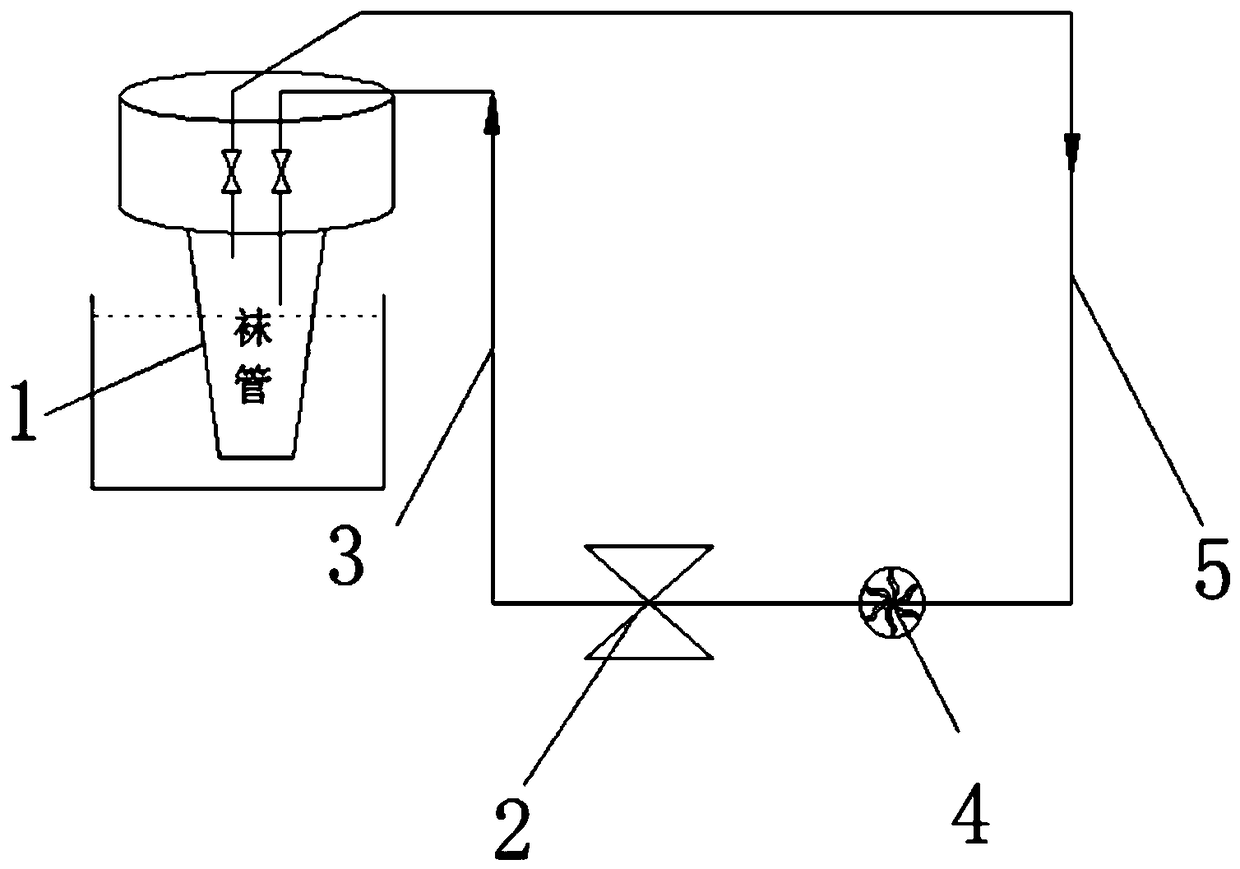

Method used

Image

Examples

Embodiment 1

[0036] 1. According to the above formula, it consists of the following parts by weight: including 1000 parts of PVDC, 3 parts of red pigment or yellow-brown pigment, 1 part of DBS, 0.5 part of internal lubricant, 0.5 part of external lubricant, 0.5 part of SiO2 , batching, and mixing in a high-speed mixer, the stirring time is controlled within 5 minutes, and the stirring temperature is controlled below 60°C. Sieve and let stand for more than 24 hours.

[0037] 2. The rotation speed of the extruder screw is 28 rpm; the process parameters of each zone are 125°C for the first zone, 155°C for the second zone, 165°C for the third zone, 158°C for the fourth zone, 158°C for the fifth zone, and 155°C for the first zone of the die head. , The second zone is 155°C, the third zone is 155°C, the temperature of the cold water tank is 8°C, the temperature of the warm water tank is 18°C, and the controlled room temperature is 25°C.

[0038] 3. The film blank is blown by compressed air and ...

Embodiment 2

[0042] 1. According to the above formula, it consists of the following parts by weight: including 1000 parts of PVDC, 3.5 parts of red pigment or yellow-brown pigment, 1.5 parts of DBS, 0.75 parts of internal lubricant, 0.75 parts of external lubricant, and 0.75 parts of SiO2 The batching is carried out, and the mixing is carried out in a high-speed mixer, the stirring time is controlled within 5 minutes, and the stirring temperature is controlled below 60°C. Sieve and let stand for more than 24 hours.

[0043] 2. The rotation speed of the extruder screw is 28 rpm; the process parameters of each zone are 130°C for the first zone, 160°C for the second zone, 170°C for the third zone, 163°C for the fourth zone, 163°C for the fifth zone, and 160°C for the first zone of the die head. , The second zone is 160°C, the third zone is 160°C, the temperature of the cold water tank is 10°C, the temperature of the warm water tank is 20°C, and the controlled room temperature is 27°C.

[004...

Embodiment 3

[0048] 1. According to the above formula, it consists of the following parts by weight: including 1000 parts of PVDC, 4 parts of red pigment or yellow-brown pigment, 2 parts of DBS, 1 part of internal lubricant, 1 part of external lubricant, and 1 part of SiO2 The batching is carried out, and the mixing is carried out in a high-speed mixer, the stirring time is controlled within 5 minutes, and the stirring temperature is controlled below 60°C. Sieve and let stand for more than 24 hours.

[0049] 2. The extruding screw speed of the extruder is 28 rpm; the process parameters of each zone are 135°C in the first zone, 165°C in the second zone, 175°C in the third zone, 168°C in the fourth zone, 168°C in the fifth zone, and 165°C in the first zone of the die head , The second zone is 165°C and the third zone is 165°C, the temperature of the cold water tank is 15°C, the temperature of the warm water tank is 22°C, and the controlled room temperature is 29°C.

[0050] 3. The film blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com