Transformer and production method thereof

A production method and transformer technology, applied in the field of transformers, can solve problems such as poor production continuity in the production cycle and cannot be continuously transferred, and achieve the effects of solving the problem of poor production continuity and inability to continuously transfer, shortening the production cycle, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

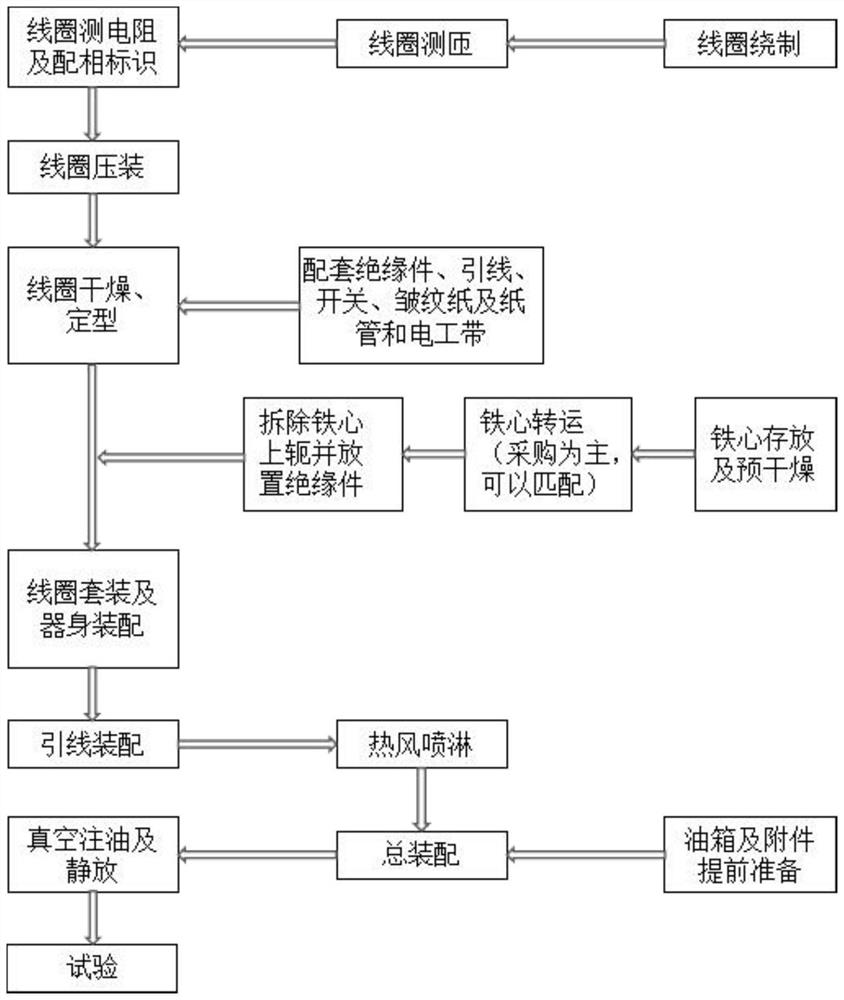

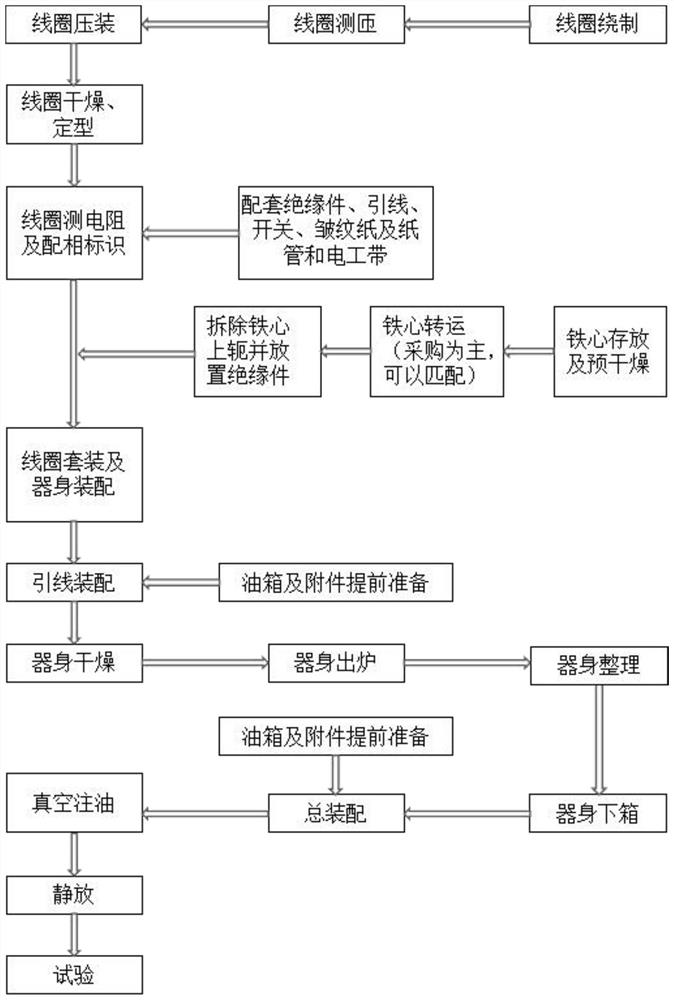

[0042] like figure 1 As shown, the present embodiment discloses a method for producing a transformer, comprising the following steps:

[0043] S1, make a coil;

[0044] S2, vacuum drying the insulating parts, lead wires and coils required in the transformer;

[0045] S3, assembling the dried coils, insulating parts and other components constituting the body to form the body;

[0046] S4, use the dried lead wire to assemble the lead wire of the body;

[0047] S5, perform general assembly on the body with the lead wires assembled.

[0048] In the method of this embodiment, the insulating parts, leads and other accessories are dried together with the coil during the drying process of the coil. Compared with the traditional production process, the drying process of the device body is cancelled, and the long process waiting time in the traditional production process is greatly reduced. , which eliminates the restriction that the body and lead wires must be stopped for 24 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com