Wafer carrying device and method for wafer rewinding

A wafer carrying and wafer technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of increasing device manufacturing costs, spending huge purchases, prolonging the process, etc., to prevent wafers from slipping, The effect of reducing production costs and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

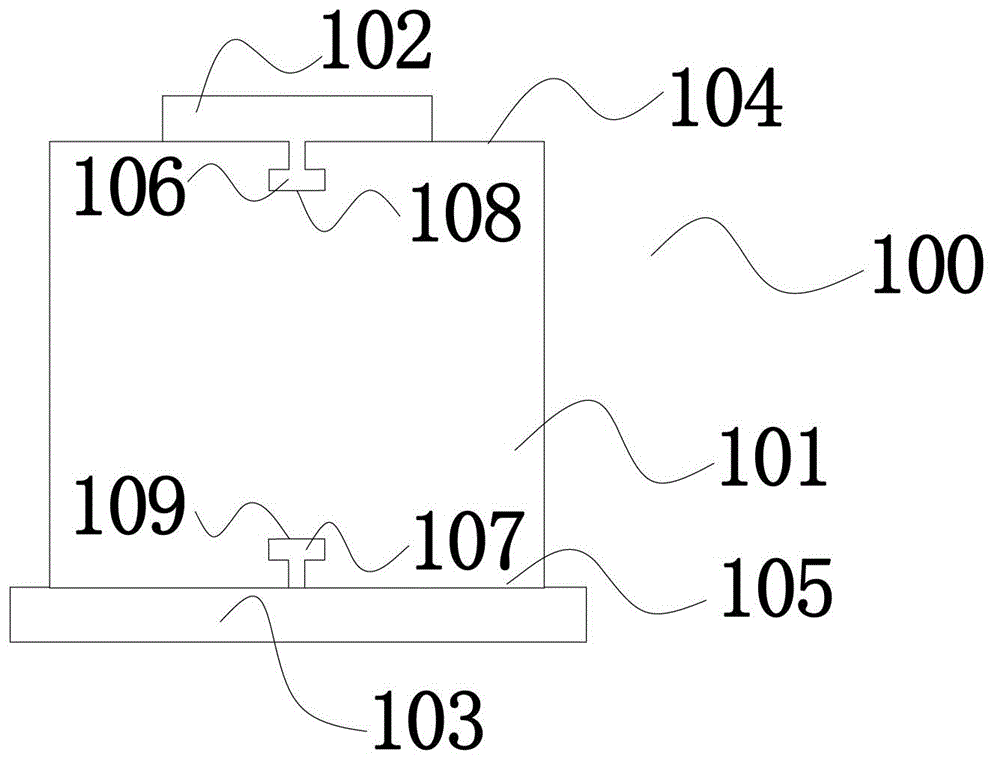

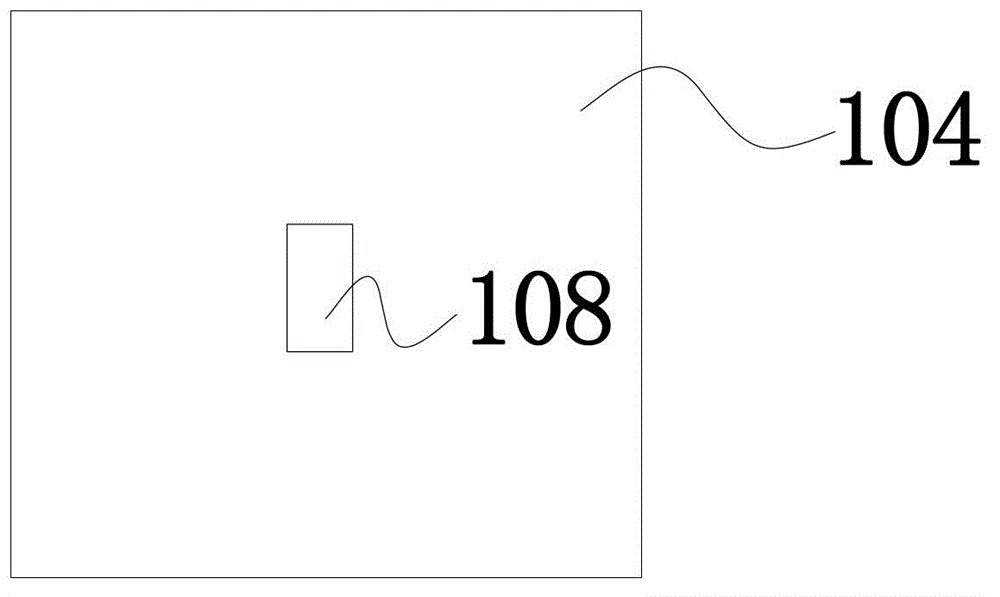

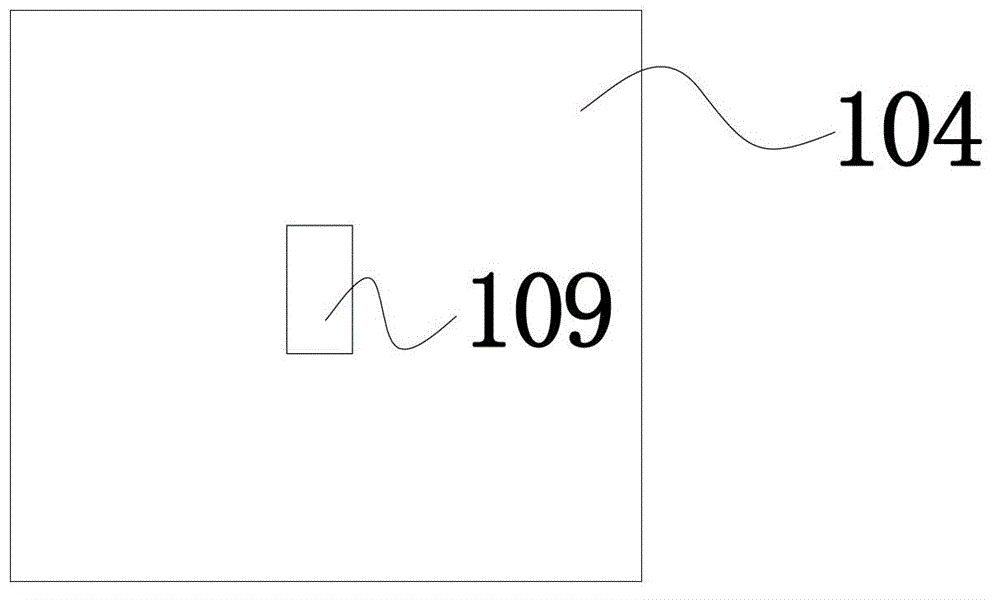

[0043] figure 1It is a schematic diagram of the front structure of the wafer carrying device provided in Embodiment 1 of the present invention; as shown in the figure, the wafer carrying device 100 includes a loading box 101, a trolley lifting module 102 and an identification and positioning module 103, wherein the loading box 101 A card slot 108 is provided on the upper surface 104 of the loading box body 101, and a card slot 109 is provided on the lower surface 105 of the loading box body 101. The card slot 108 and the card slot 109 have the same shape and size; Lifting structure (not shown in the figure), the lower surface of the trolley lifting module 102 is provided with a snap joint 106, and the lower surface of the identification and positioning module 103 is provided with an identification and positioning hole (not shown in the figure), the identification and positioning module 103 The upper surface is provided with a card connector 107, the above-mentioned card connec...

Embodiment 2

[0055] Figure 7 It is a schematic flow chart of the method for wafer rewinding provided by Embodiment 2 of the present invention; as shown in the figure, a detachable trolley lifting module and an identification and positioning module are set on the loading box of a wafer carrying device; reloading The wafer is placed in the loading box; then when the wafer needs to be rewound during the process production, the positions of the trolley lifting module and the identification and positioning module are exchanged, and the loading box is turned over to rewind the wafer ; Finally, the wafer carrying device is transferred to the top of the corresponding process machine by the lifting module of the lifting trolley, and the wafer carrying device is loaded onto the process machine by using the identification and positioning module.

[0056] Wherein, the loading box body also includes a loading box cover plate, and the loading box cover plate is provided with multiple sets of carrying c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com