Desulfurization treatment process applied to furfural residue combustion

A treatment process and furfural slag technology, which is applied in the direction of combustion product treatment, combustion type, fuel supply, etc., can solve the problems of inability to obtain desulfurization effect, complex composition, high moisture content, low exhaust temperature, strong corrosion of equipment, etc. , to achieve the effect of enhancing sulfur fixation, avoiding excessive scaling, and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

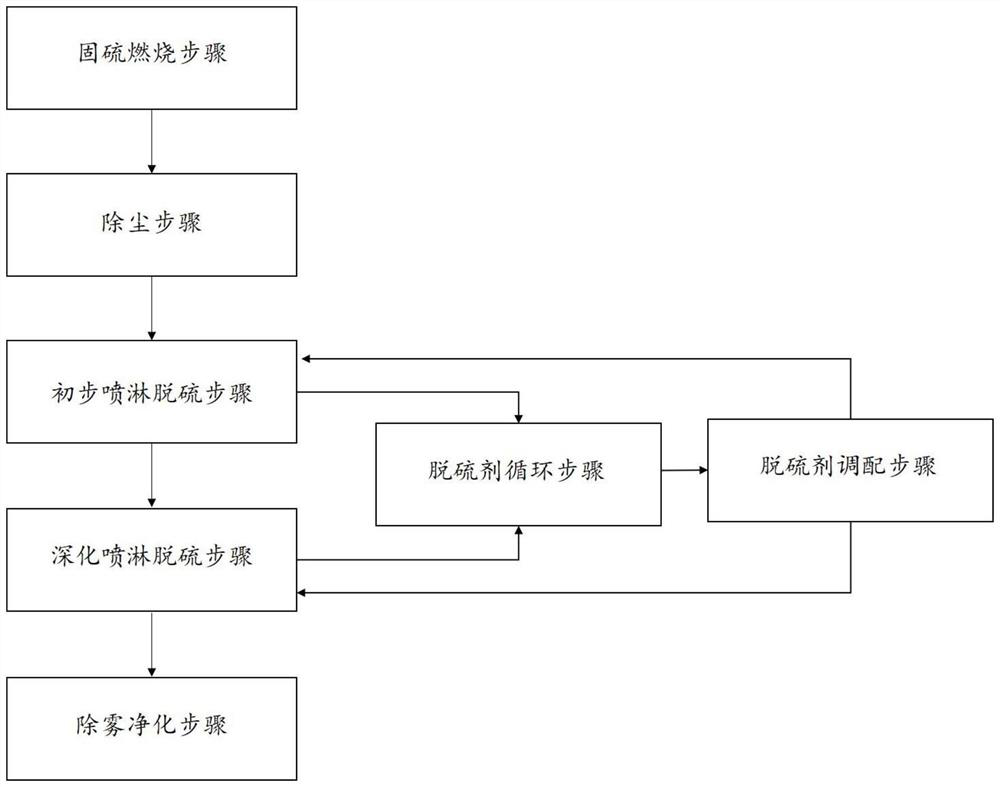

Method used

Image

Examples

Embodiment 1

[0041] Example 1:

[0042] Adding Ca(OH) to furfural slag fuel 2 、Ba(OH) 2 、Al 2 o 3 Composite sulfur-fixing agent constituted, the Ca(OH) in the composite sulfur-fixing agent 2 The proportion is 97.5 parts by weight, Ba(OH) 2 2.5 parts by weight, Al 2 o 3 3 parts by weight. And according to the sulfur element content detected in the furfural slag fuel sample, the addition amount of the composite sulfur-fixing agent was adjusted so that the molar ratio of Ca and S elements was 3.8. After the furfural slag and sulfur-fixing agent are fully mixed, they are ground and crushed to fine particles with a particle size of 0.1 mm, and then sent to a furfural slag combustion furnace for combustion, and the combustion temperature is controlled at 870 degrees Celsius.

[0043] For the flue gas produced by the combustion of furfural slag, dust removal is carried out by combining cyclone dust removal and filter bag dust removal.

[0044] The flue gas after dust removal is input to ...

Embodiment 2

[0048] Example 2

[0049] Adding Ca(OH) to furfural slag fuel 2 , KOH, Al 2 o 3 Composite sulfur-fixing agent constituted, the Ca(OH) in the composite sulfur-fixing agent 2 The proportion is 98.5 parts by weight, KOH1.5 parts by weight, Al 2 o 3 2 parts by weight. And according to the sulfur content detected in the furfural slag fuel sample, the amount of composite sulfur fixative was adjusted so that the molar ratio of Ca and S was 3. After the furfural slag and sulfur-fixing agent are fully mixed, they are ground and crushed to fine particles with a particle size of 0.1 mm, and then sent to a furfural slag combustion furnace for combustion, and the combustion temperature is controlled at 890 degrees Celsius.

[0050] For the flue gas produced by the combustion of furfural slag, dust removal is carried out by combining cyclone dust removal and filter bag dust removal.

[0051] The flue gas after dust removal is input to the desulfurization spraying equipment for prelim...

Embodiment 3

[0055] Example 3

[0056] Adding Ca(OH) to furfural slag fuel 2 、Na 2 CO 3 、Al 2 o 3 Composite sulfur-fixing agent constituted, the Ca(OH) in the composite sulfur-fixing agent 2 The proportion is 99 parts by weight, 1 part by weight of KOH, Al 2 o 3 2 parts by weight. And according to the sulfur content detected in the furfural slag fuel sample, the amount of composite sulfur fixative was adjusted so that the molar ratio of Ca and S was 2.5. After the furfural slag and sulfur-fixing agent are fully mixed, they are ground and crushed to fine particles with a particle size of 0.1 mm, and then sent to a furfural slag combustion furnace for combustion, and the combustion temperature is controlled at 850 degrees Celsius.

[0057] For the flue gas produced by the combustion of furfural slag, dust removal is carried out by combining cyclone dust removal and filter bag dust removal.

[0058] The flue gas after dedusting is input to the desulfurization spraying equipment for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com