Environment-friendly brick prepared from solid waste solidified soil and preparation method of environment-friendly brick

A technology for solid waste and solid waste, applied in the field of building materials, can solve the problem that solid waste cannot be processed in a large area, and achieve the effect of reducing energy consumption, excellent frost resistance and carbonization performance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

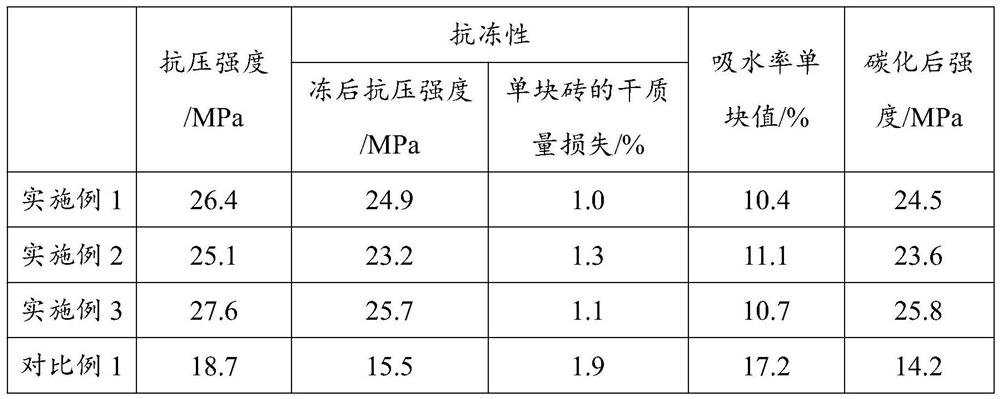

Examples

Embodiment 1

[0034] A preparation method of an environmentally friendly brick prepared by utilizing solid waste solidified soil, specifically comprising the following steps:

[0035] The first step: drying, crushing, and sieving the solid waste to a particle size of ≤ 1 mm, and proportioning 30 parts of glycerol, 20 parts of fatty acids, 5 parts of polyacrylamide, and 12 parts of sodium hydroxide according to the parts by mass. parts, 2 parts of calcium sulfoaluminate, 2 parts of triethanolamine, 4 parts of sodium silicate, and 40 parts of water. solidified solid waste.

[0036] The second step: the solidified solid waste was aged at 15°C for 0.5 h to obtain solid waste solidified soil.

[0037] The third step: 45 parts of the aged solid waste solidified soil; 15 parts of construction waste aggregate with a particle size of 0.5-1.5mm; 10 parts of Portland cement with a strength grade of 42.5; 20 parts of water According to the mixing ratio, add it to the mixer and mix evenly, and the mix...

Embodiment 2

[0041] A preparation method of an environmentally friendly brick prepared by utilizing solid waste solidified soil, specifically comprising the following steps:

[0042] The first step: drying, crushing, and sieving the solid waste to a particle size of ≤ 1 mm, and proportioning 50 parts of glycerol, 30 parts of fatty acids, 10 parts of polyacrylamide, and 20 parts of sodium hydroxide according to the parts by mass. parts, 3 parts of calcium sulfoaluminate, 8 parts of triethanolamine, 10 parts of sodium silicate, and 70 parts of water. solidified solid waste.

[0043] The second step: aging the solidified solid waste at 25°C for 10 h to obtain solid waste solidified soil.

[0044] The third step: 70 parts of the aged solid waste solidified soil; 30 parts of industrial waste slag aggregate with a particle size of 0.5-1.5mm; 10 parts of grade I fly ash; strength grade 52.5 white silicon 15 parts of salt cement; 10 parts of water are added to the mixer according to the mixing r...

Embodiment 3

[0049] A preparation method of an environmentally friendly brick prepared by utilizing solid waste solidified soil, specifically comprising the following steps:

[0050] The first step: drying, crushing, and sieving the solid waste to a particle size of ≤ 1 mm, and proportioning 40 parts of glycerol, 25 parts of fatty acids, 8 parts of polyacrylamide, and 16 parts of sodium hydroxide according to the parts by mass. parts, 2.5 parts of calcium sulfoaluminate, 5 parts of triethanolamine, 7 parts of sodium silicate, and 55 parts of water. solidified solid waste.

[0051] The second step: the solidified solid waste was aged at 20°C for 5 hours to obtain solid waste solidified soil.

[0052] The third step: 60 parts of the aged solid waste solidified soil; 25 parts of construction waste aggregate with a particle size of 0.5-1.5mm; 5 parts of Class II fly ash; strength grade 52.5 ordinary silicon 13 parts of salt cement; 15 parts of water are added to the mixer according to the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com