Self-adhesive PE (polyethylene) protective film

A protective film and self-adhesive technology, applied in the field of protective film, can solve the problems of insecure adhesion of the protective film, easy warping of the protective film, poor application effect, etc., to improve the application effect, not easy to warp, and improve the product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

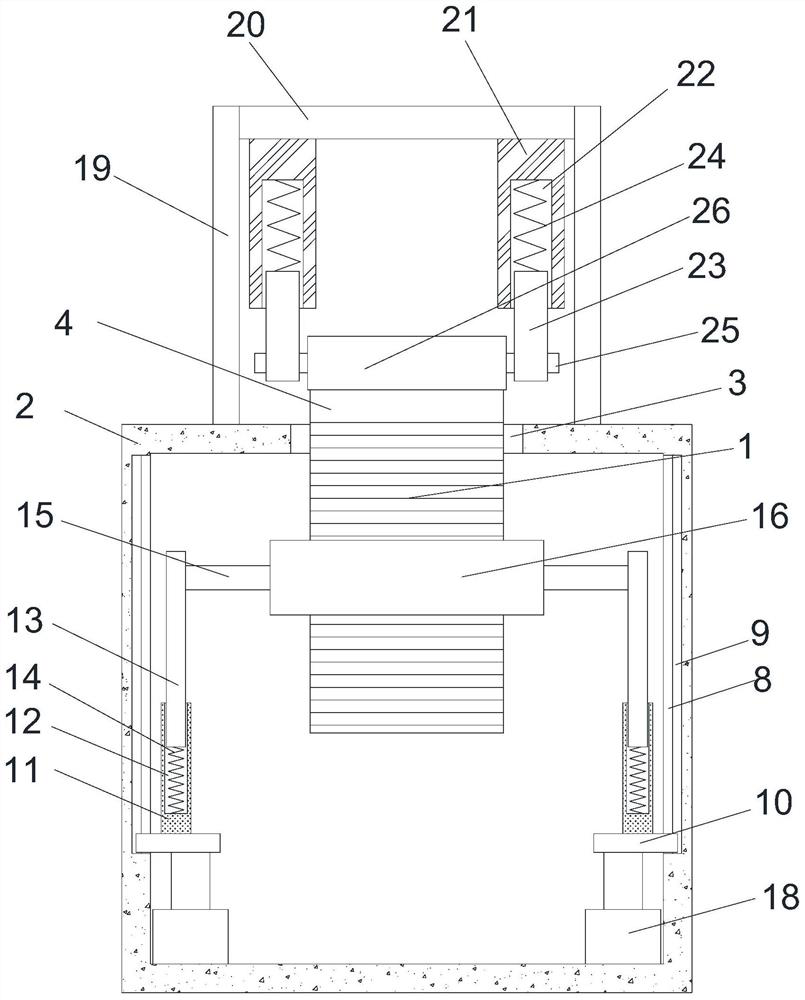

[0050] The embodiment of the present invention provides a self-adhesive PE protective film, such as Figure 1-Figure 6 As shown, it includes: a protective film body 1, a casing 2 and a sticking assembly, a fixing assembly is arranged in the casing 2, and the protective film body 1 is installed in the casing 2 through the fixing assembly, and the casing 2. A through hole 3 is provided on the upper surface, the upper side of the protective film body 1 extends through the through hole 3 to the outside of the casing 2, and the application component is located directly above the protective film body 1.

[0051] The working principle and beneficial effects of the above technical solutions are as follows: a self-adhesive PE protective film provided by the present invention includes a protective film body 1, a casing 2 and an application component, a protective film body 1, a casing 2 and an application The three components are used together. The protective film body 1 is arranged in ...

Embodiment 2

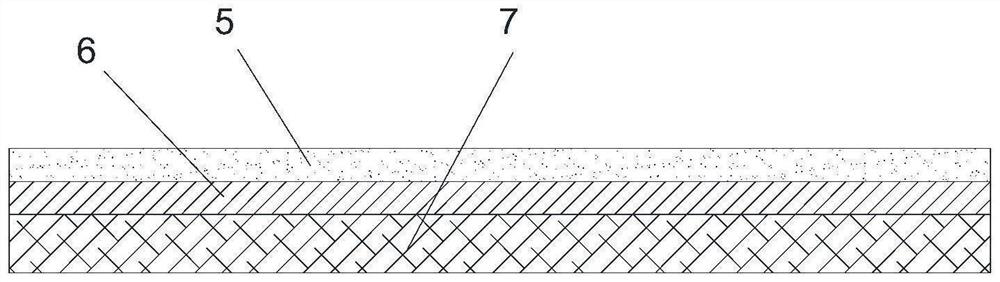

[0053] On the basis of the above Example 1, as Figure 1-Figure 4 As shown, the protective film body 1 is made of a three-layer co-extrusion blown film of a self-adhesive layer 5, an intermediate layer 6 and a protective layer 7, and the intermediate layer 6 is located between the protective layer 7 and the self-adhesive layer 5. between;

[0054] The self-adhesive layer 5 includes metallocene polyethylene, the intermediate layer 6 includes low density polyethylene, and the protective layer 7 includes polypropylene resin and low density polyethylene;

[0055] The fixed assembly includes:

[0056] Two first sliding grooves 8, the two first sliding grooves 8 are symmetrically arranged on the inner walls of the left and right sides of the casing 2;

[0057] The first slide rail 9, the inner walls of the two first slide grooves 8 are respectively provided with a first slide rail 9, the first slide rail 9 is arranged vertically, and the side wall of the first slide rail 9 is conn...

Embodiment 3

[0065] On the basis of Example 2, as figure 1 , Figure 4 As shown, a first electric telescopic rod 18 is arranged below the first slider 10, one end of the first electric telescopic rod 18 is fixedly connected to the inner wall of the bottom of the housing 2, and the other end of the first electric telescopic rod 18 is connected to the bottom inner wall of the housing 2. The lower surface of the first slider 10 is fixedly connected.

[0066] The working principle and beneficial effects of the above technical solutions are: with the use of the protective film body 1, the thickness of the protective film body 1 wound on the film roll 16 is gradually reduced, in order to ensure that the protective film body 1 always exceeds the upper end of the through hole 3. Height, a first electric telescopic rod 18 is arranged under the first slider 10. When the actual height of the protective film body 1 beyond the through hole 3 is lower than the preset height, the first electric telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com