Grinding and polishing device for fan blades and working method of grinding and polishing device

A technology of fan blade and polishing device, which is applied in the directions of grinding drive device, grinding/polishing equipment, grinding workpiece support, etc., can solve the problem of inability to adjust the position of the material-moving mechanism

Active Publication Date: 2022-06-21

WEIFANG UNIV OF SCI & TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The problem to be solved by the present invention is to provide a grinding and polishing device for fan blades and its working method, which solves the problem that the existing grinding and polishing device cannot be loaded according to the position of the grinding and polishing mechanism. The automatic feeding operation of the mechanism requires separate program control, and at the same time it cannot be adjusted according to the position of the material shifting mechanism to realize the technical problem of rotating the fan blades

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

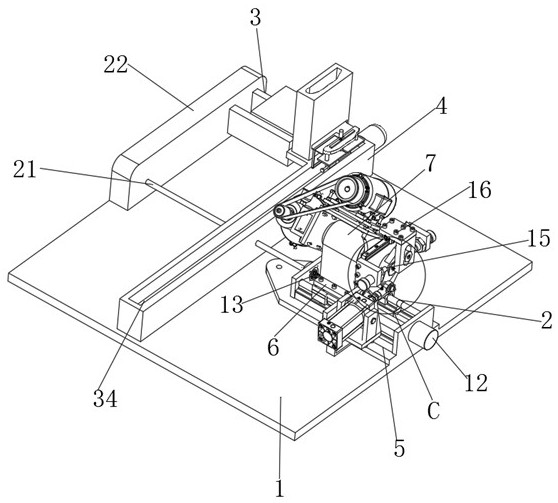

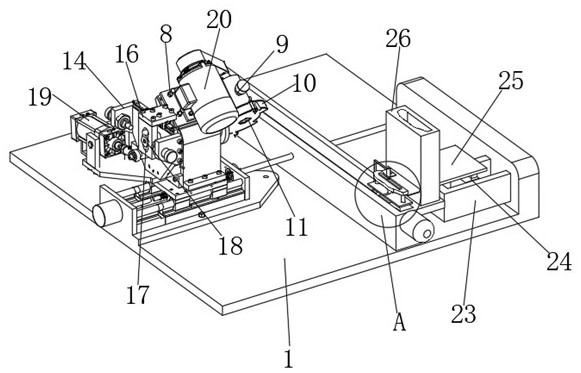

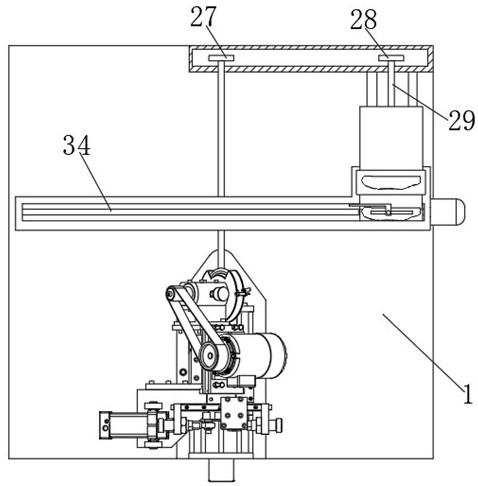

The grinding and polishing device comprises a base, a grinding and polishing mechanism, a feeding mechanism and a material moving mechanism, the grinding and polishing mechanism, the feeding mechanism and the material moving mechanism are installed on the base, the grinding and polishing mechanism comprises a first adjusting seat, a sliding seat is installed on the first adjusting seat in a sliding mode, and the first adjusting seat is provided with a second adjusting seat. A fixed seat is mounted on the sliding seat, a U-shaped rotating seat is rotatably mounted on the fixed seat, a transmission seat is mounted on the rotating seat, an outer cover is mounted on the transmission seat, and a grinding disc is rotatably mounted in the outer cover; the machined fan blades are pushed inwards to fall on the base, automatic discharging of the fan blades is achieved, and automatic feeding and discharging operation of the fan blades is achieved according to the position state of a grinding disc of the grinding and polishing mechanism.

Description

technical field [0001] The invention relates to the technical field of fan blade processing, in particular to a grinding and polishing device for fan blades and a working method thereof. Background technique [0002] During the processing of the fan blade, the outer edge needs to be ground and polished. [0003] When the existing grinding and polishing device is working, it is impossible to realize the automatic feeding operation of the feeding mechanism according to the position of the grinding and polishing mechanism. The rotation of the fan. Contents of the invention [0004] The problem to be solved by the present invention is to provide a grinding and polishing device for fan blades and its working method, which solves the problem that the existing grinding and polishing device cannot be loaded according to the position of the grinding and polishing mechanism. The automatic feeding operation of the mechanism requires separate program control, and at the same time it...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24B19/14B24B29/02B24B41/06B24B47/22B24B47/16B24B41/02

CPCB24B19/14B24B29/02B24B41/06B24B47/22B24B47/16B24B41/02

Inventor 范绍玉杨中秀

Owner WEIFANG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com