Full-automatic drill cutting cleaning machine and cleaning method thereof

A fully automatic cleaning and drilling cuttings technology, which is applied in construction and other fields, can solve the problems of difficult to meet the technical requirements of drilling and mud logging, heavy tasks, cumbersome work, etc., achieve good filtering effect, small equipment size, and improve cleaning efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

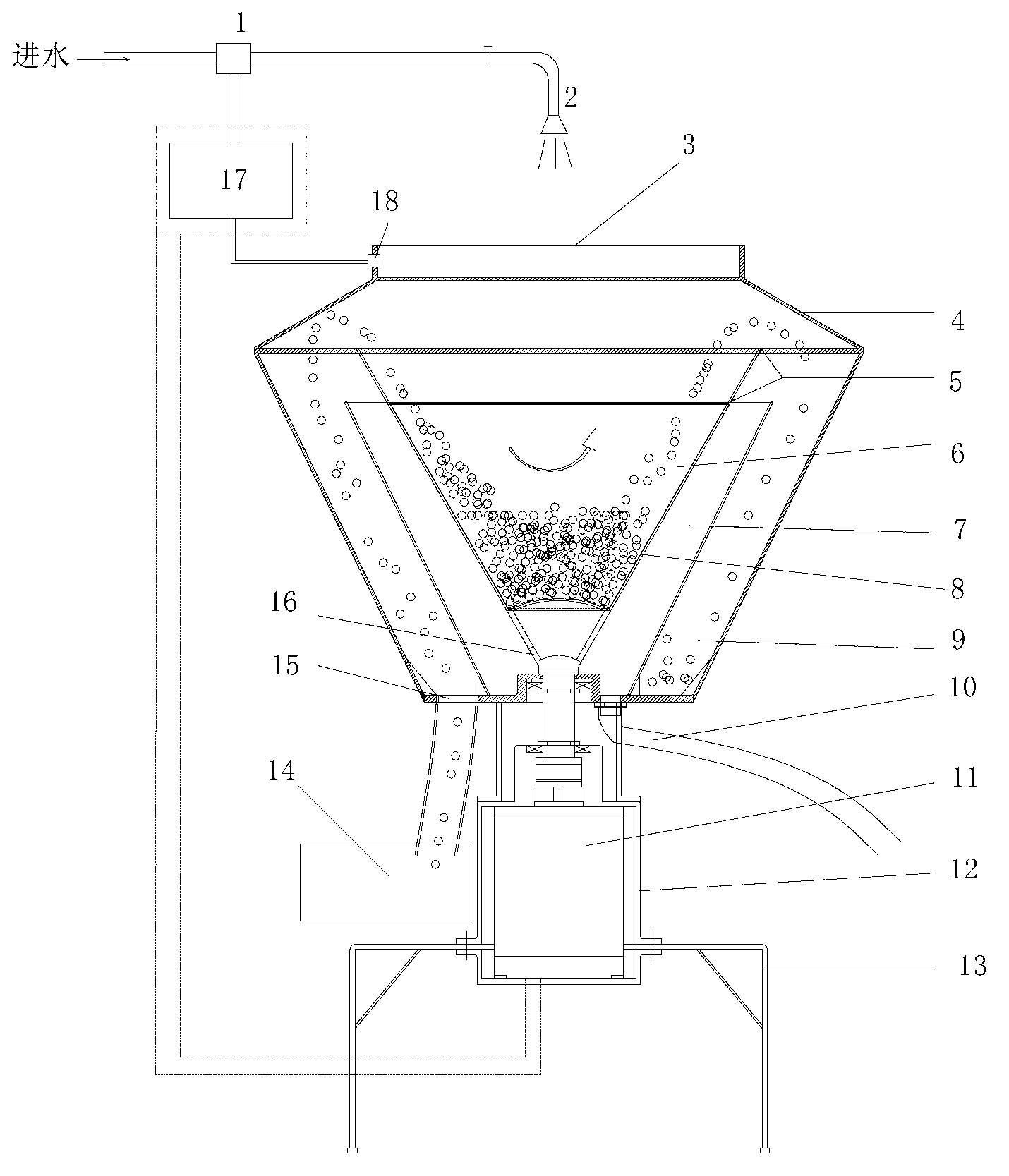

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0030] As shown in the accompanying drawings, the present invention is a full-automatic cleaning machine for drilling cuttings, which includes a sand collecting chamber 9, and a sand retaining plate 4 is provided at the sand sending port 3 on the top of the sand collecting chamber 9, so as to avoid sand and gravel from being scattered to the ground during the sand adding process. external. A waste water chamber 7 is arranged in the sand collection chamber 9, and a funnel-shaped sand washing bucket 6 with a cone angle ranging from 60° to 70° is arranged in the waste water chamber 7. The side of the sand washing bucket 6 can leak water, and the inner wall is made of 80 mesh. Stainless steel strainer 8 forms. The upper edge 5 of the sand washing bucket 6 is higher than the waste water chamber 7, and the side of the upper edge 5 is sealed and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com