Open chain belt type barrel plating machine

A chain-belt and chain-belt technology, which is applied in the field of open chain-belt barrel plating machines, can solve the problems of multiple electroplating solutions, decrease in the appearance of the coating, and fast consumption of main metal ions, so as to ensure the qualified rate of products and the surface quality of plated parts. Good, wide range of part sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

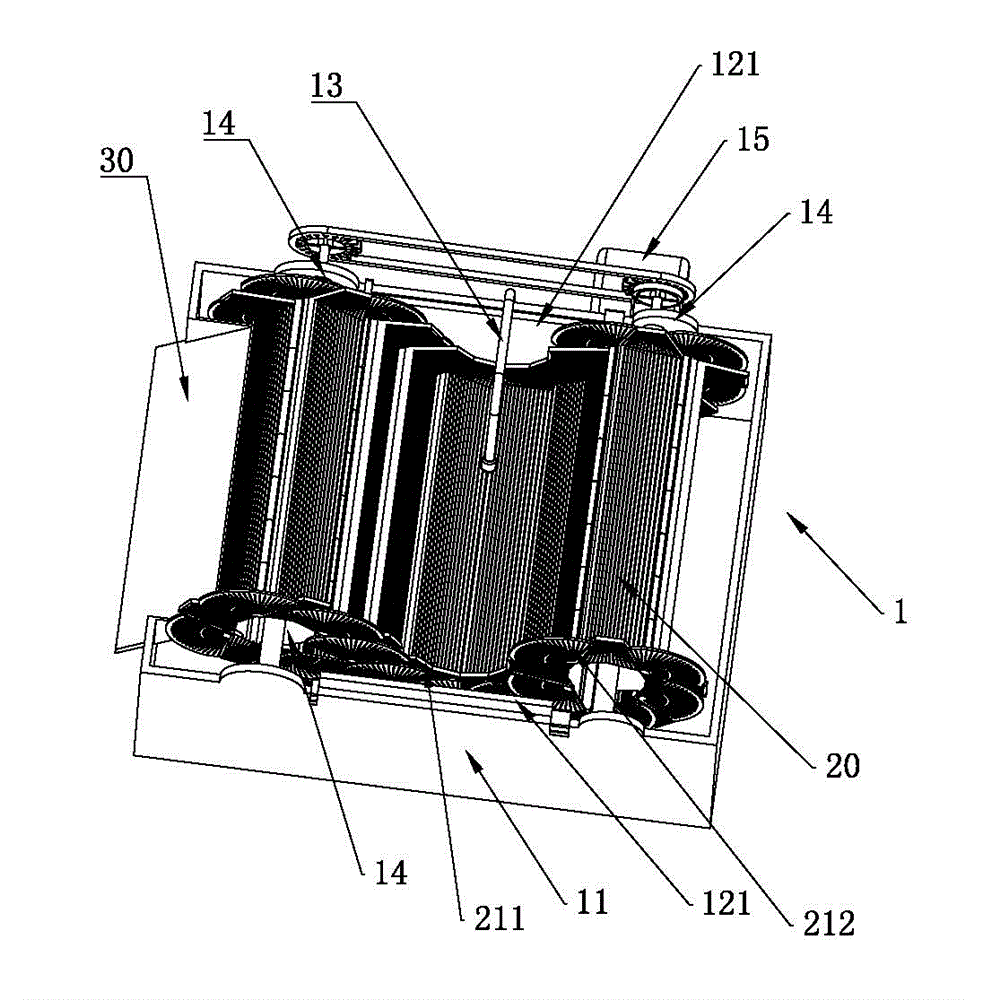

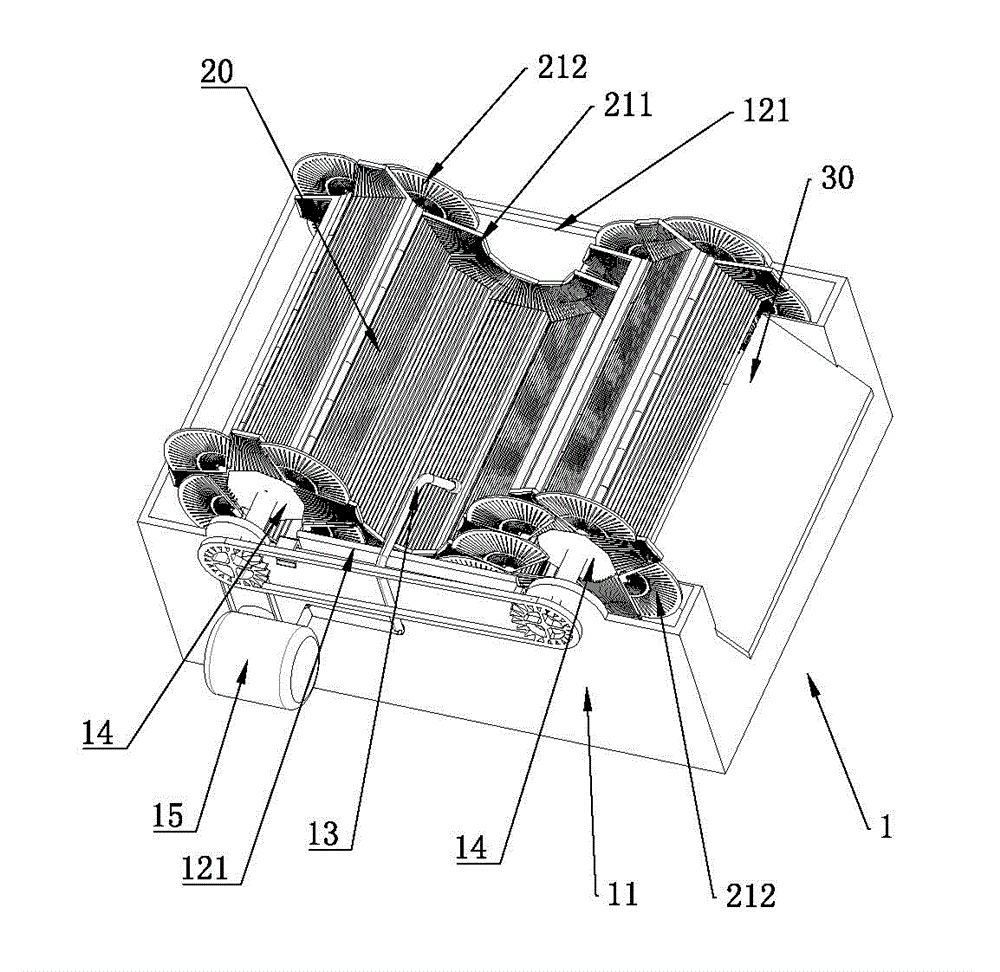

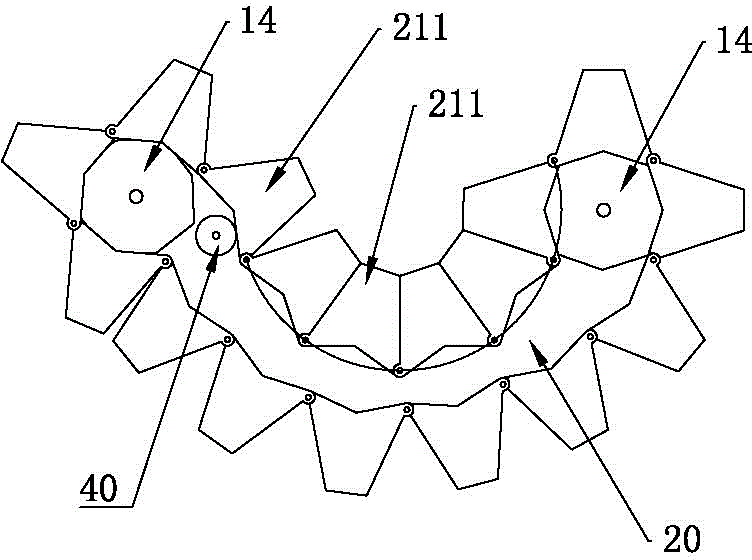

[0041] see Figure 1 to Figure 5 , an open chain-belt type barrel plating machine 1, comprising an electroplating tank 11 for containing the electroplating solution, an anode plate 121 and a cathode lead 13 placed in the electroplating tank 11, and a control device for controlling the operation of the entire equipment, and the control devices are respectively It is electrically connected with the anode plate 121 and the cathode lead 13; the open chain belt type barrel plating machine 1 also includes a chain belt 20 placed in the electroplating tank 11, a transmission wheel 14 that drives the chain belt 20 to move left and right, and a driving transmission wheel 14 The motor 15; the motor 15 is electrically connected to the control device; the chain belt 20 is placed in the electroplating tank 11 in an arc shape, and the center of the arc where the chain belt 20 is located is located above the chain belt 20; the chain belt 20 is set There are a plurality of liquid-permeable hol...

Embodiment 2

[0049] see Figure 6 and Figure 7 , the difference between this embodiment and Embodiment 1 is:

[0050] The chain belt 20 is an integral soft belt 22, and the front baffle and the rear baffle are respectively provided with arc grooves matching the arc of the soft belt 22, and the soft belt 22 is formed by the transmission wheel 14 and The arc-shaped trunking is supported in an arc shape. Described soft belt 22 can adopt PVC soft belt.

[0051] Wherein, a plurality of retaining bars 23 are hinged on the soft belt 22, and the retaining bars 23 are evenly placed on the soft belt 22; When the soft belt 22 moves to the right, the bar 23 falls to the left due to its own gravity; when the soft belt 22 moves to the left, the fixing part clamps the bar 23, and the bar 23 is parallel to the horizontal plane or the right end of the bar is inclined upward .

[0052] Wherein, the baffle plate includes a front baffle plate and a rear baffle plate, and the front baffle plate and the r...

Embodiment 3

[0055] see Figure 8 and Figure 9 The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the anode plate 122 is arranged above the chain belt 20 and the workpiece 10 to be plated, and the front and rear ends of the anode plate 122 are respectively fixed in the electroplating tank 11 front and rear sides. The anode plate 122 is placed above the workpiece 10 to be plated, and it is submerged by the electroplating solution. At this time, the electroplating solution can be exchanged between the anode and the cathode without hindrance, and the electroplating is more uniform and of higher quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com