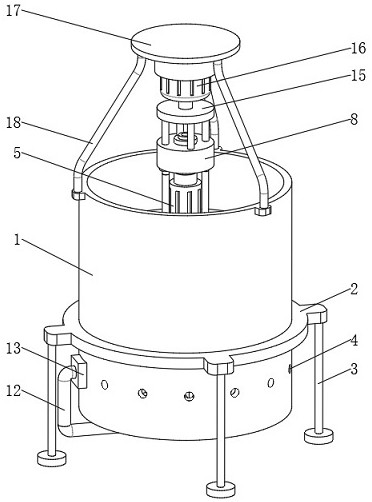

Extraction device for camellia oil processing

An extraction device and camellia oil technology are applied in solvent extraction, solid solvent extraction, cleaning methods and utensils, etc., which can solve problems such as blockage of filter holes, large extraction tank volume, and influence on the processing process, so as to avoid blockage, uniform heating, and non-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

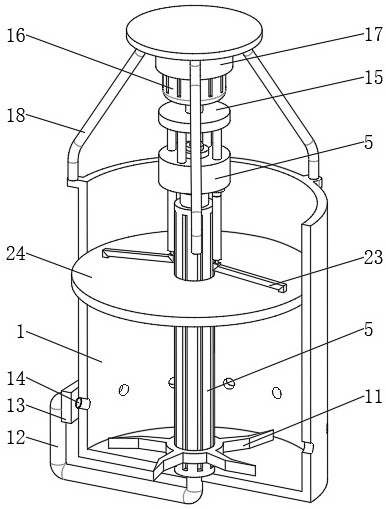

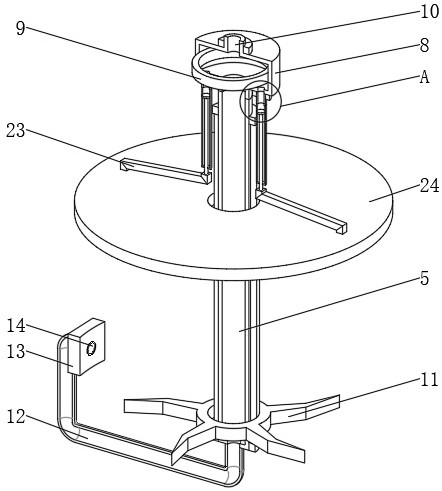

[0021] In this embodiment, specifically: the left and right sides of the bottom end of the oil storage tank 8 are fixedly connected with a fixed sleeve 20, the inside of the fixed sleeve 20 is fixedly installed with a solenoid valve 19, and the piston rod 22 runs through the bottom end of the fixed sleeve 20 and is fixedly installed. There is a piston plate 21, and the movable socket between the piston plate 21 and the fixed sleeve 20 can open the solenoid valve 19 located at the top of the fixed sleeve 20, so that the oil in the oil storage tank 8 can be exported through the fixed sleeve 20 and given to the piston. Plate 21 presses, and drives the piston plate 21 and piston rod 22 to move down, thereby providing downward pressure on the pressure rod 23, and at the same time providing downward pressure on the pressure plate 24, and then pressurizing the extraction raw materials through the pressure plate 24 to increase the extraction efficiency. The use of cylinders for pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com